Method for preparing feldspar powder concentrate by mineral separation of aeolian sand in desert

A technology of desert aeolian sand and feldspar powder, which is applied in the field of industrial utilization of desert aeolian sand, and can solve the problems that cannot be directly used in the ceramic industry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

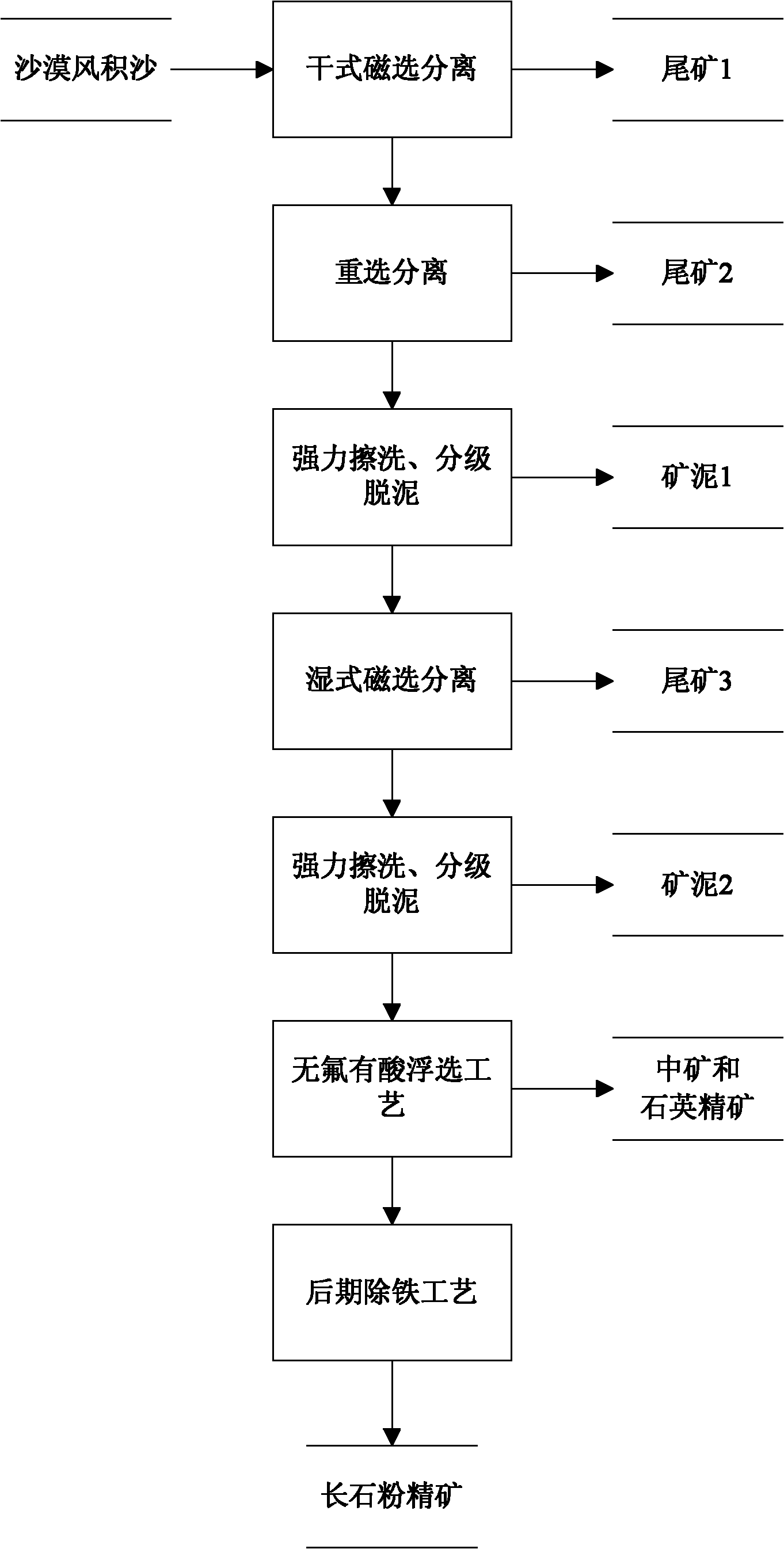

[0040] The Mu Us Desert is located in the intersection area of Inner Mongolia, Shaanxi and Ningxia. The desert covers an area of more than 30,000 square kilometers and is one of the eight major deserts in my country. In this embodiment, the aeolian sand of the Mu Us Desert is used as raw material, by using figure 1 Shown beneficiation method of the present invention prepares and produces the feldspar powder concentrate product (Fe 2 o 3 content≤0.2%), the specific preparation method and process are as follows:

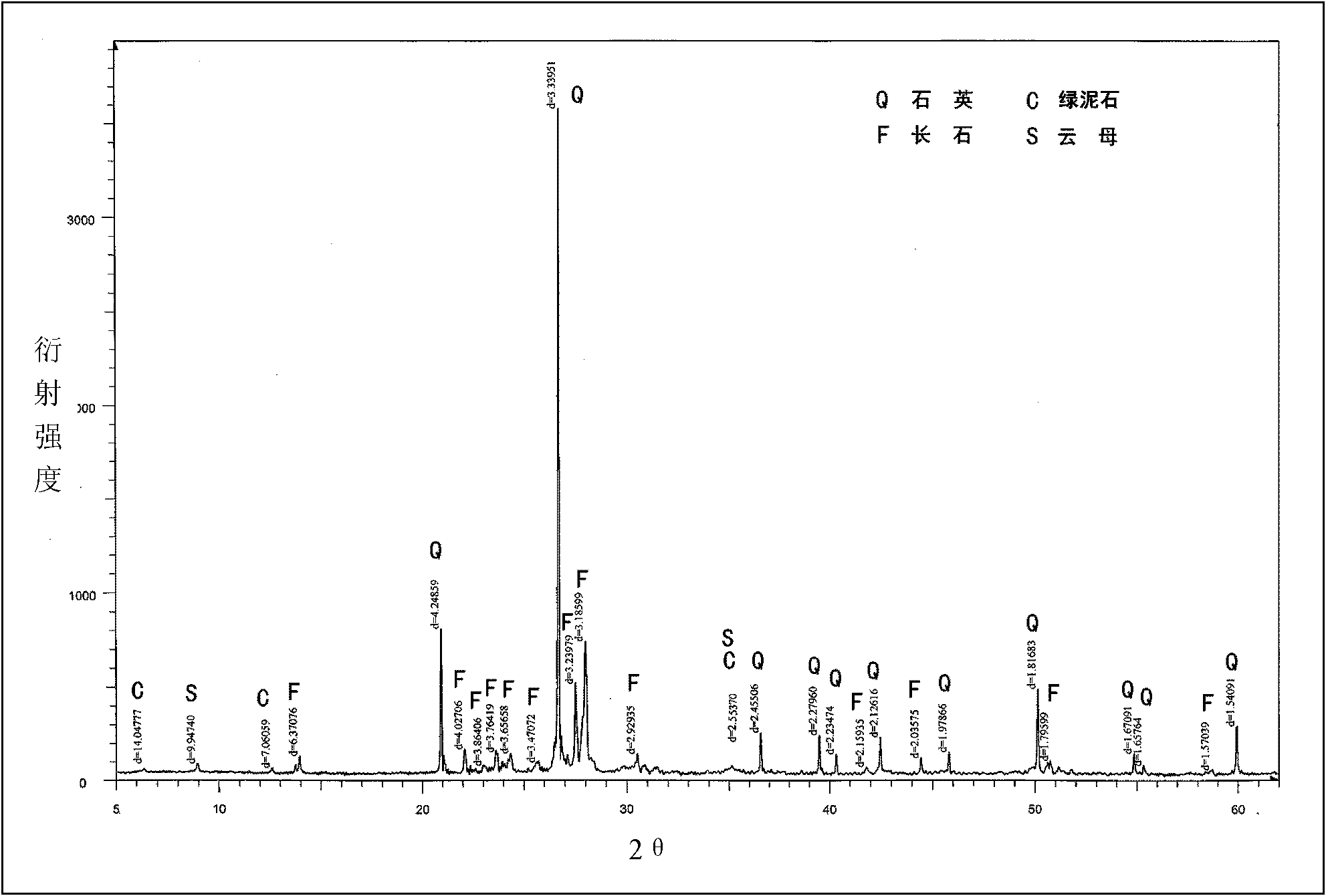

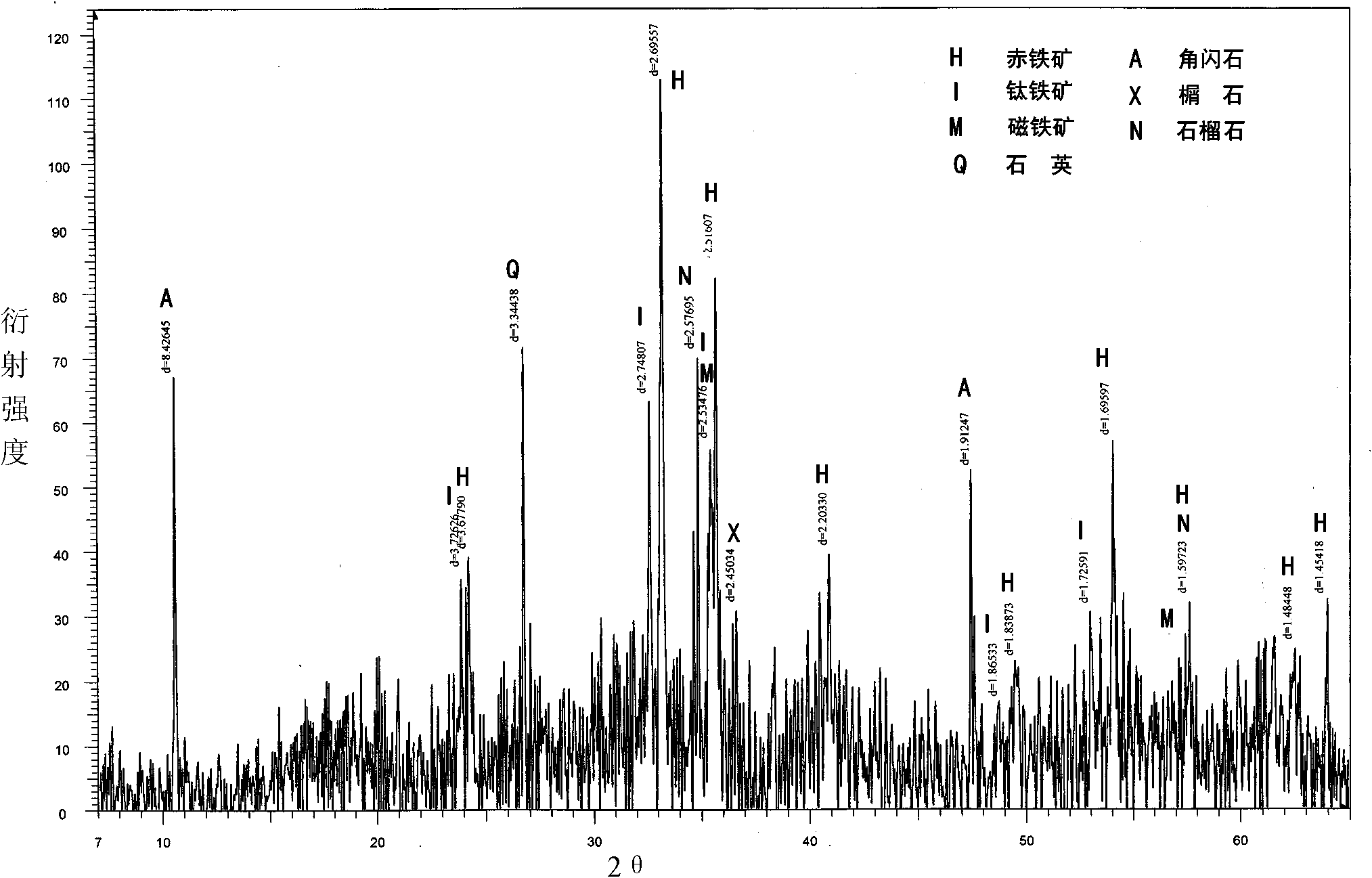

[0041] 1. Raw ore sample analysis

[0042] The desert aeolian sand raw ore sample selected in this example is in the shape of fine sand, and the particle size of the sand is mostly below 0.5 mm, which is relatively uniform; the overall color is earthy yellow to the naked eye, and a small amount of black particles can be seen in it.

[0043] 1.1 Chemical composition analysis of raw ore samples

[0044] The results of multi-element chemical composition analysis o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com