Device and method for continuously preparing active carbon by biomass in bulk

A technology for preparing activated carbon and biomass, which is applied in the direction of climate sustainability, chemical instruments and methods, sustainable manufacturing/processing, etc., and can solve low heat utilization efficiency, low drying/carbonization/activation efficiency, discontinuous production process, etc. problems, to achieve high heat utilization efficiency, continuous production, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

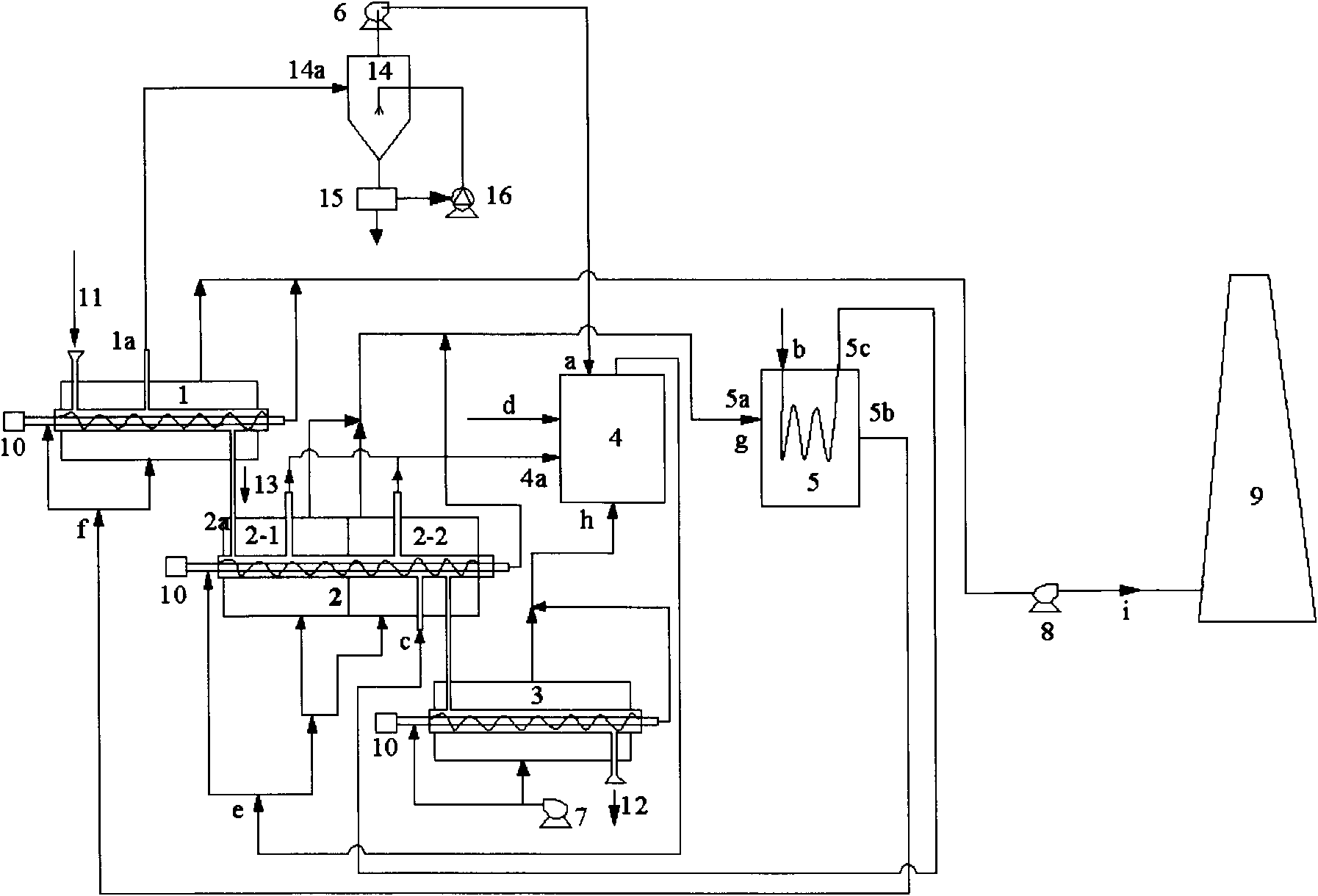

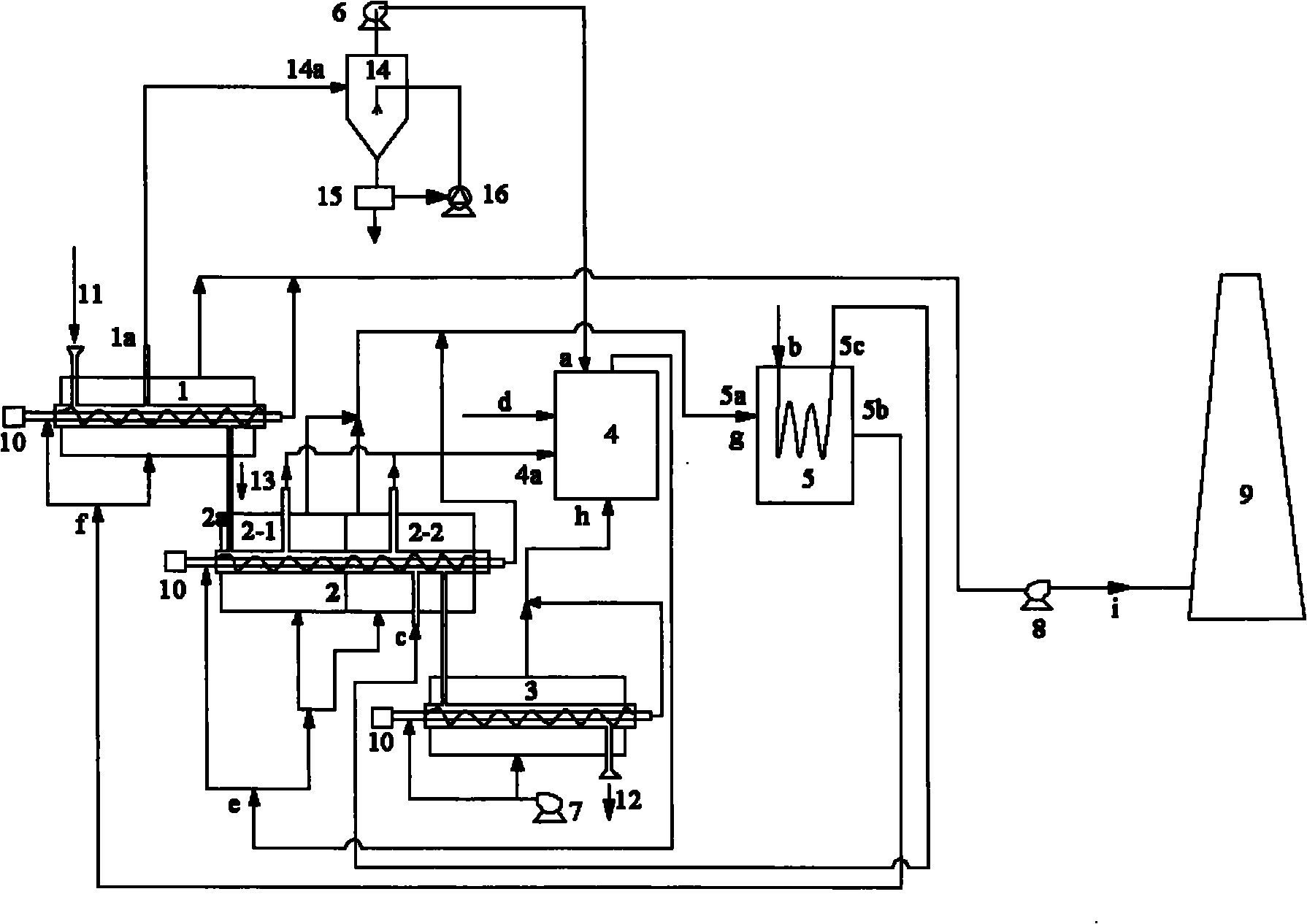

[0031] The present invention will be further described below in conjunction with the drawings.

[0032] The invention is a device and method for continuously preparing activated carbon in batches using biomass. The drying, carbonization, activation and cooling of biomass all adopt a spiral coil structure with internal and external heating methods, which can be carried out in continuous and uninterrupted conditions. Can realize continuous production. The time and temperature required for biomass drying, carbonization and activation can be easily adjusted by adjusting the rotating speed of the coil shaft and the heating flue gas temperature. The non-condensable gas, combustible gas and tar produced during the production process are all sent to the waste heat boiler for heat utilization. The entire system has high heat utilization efficiency, low energy consumption per unit product, and no secondary pollution.

[0033] See figure 1 The device for continuously preparing activated ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com