Rapid shaping automatic powder feeding and spreading device

The technology of powder spreading device and powder feeding device is applied in the field of automatic powder feeding and powder spreading device for rapid prototyping, which can solve the problems of low work efficiency, complex structure, and low powder supply accuracy, and achieves convenient loading and unloading, and solves complex structure and layout. tightening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

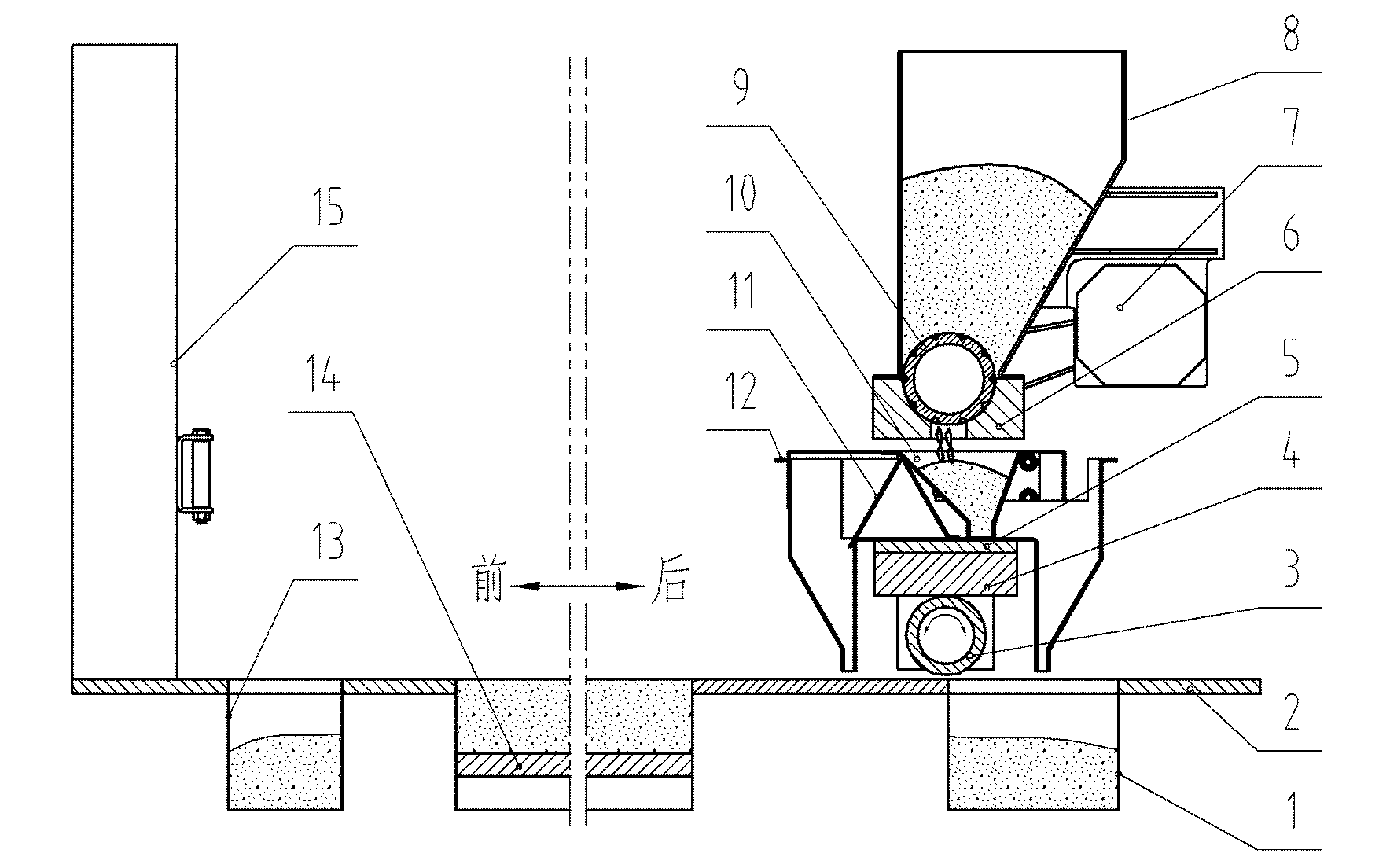

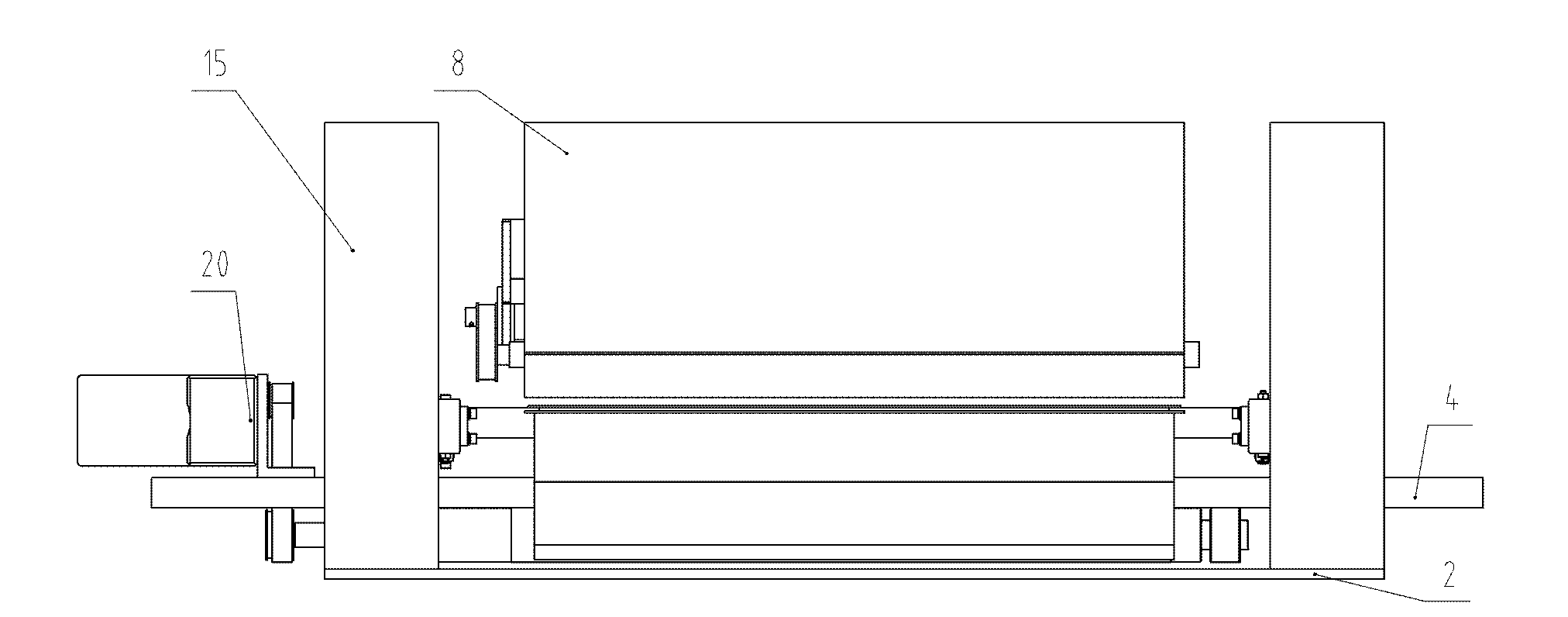

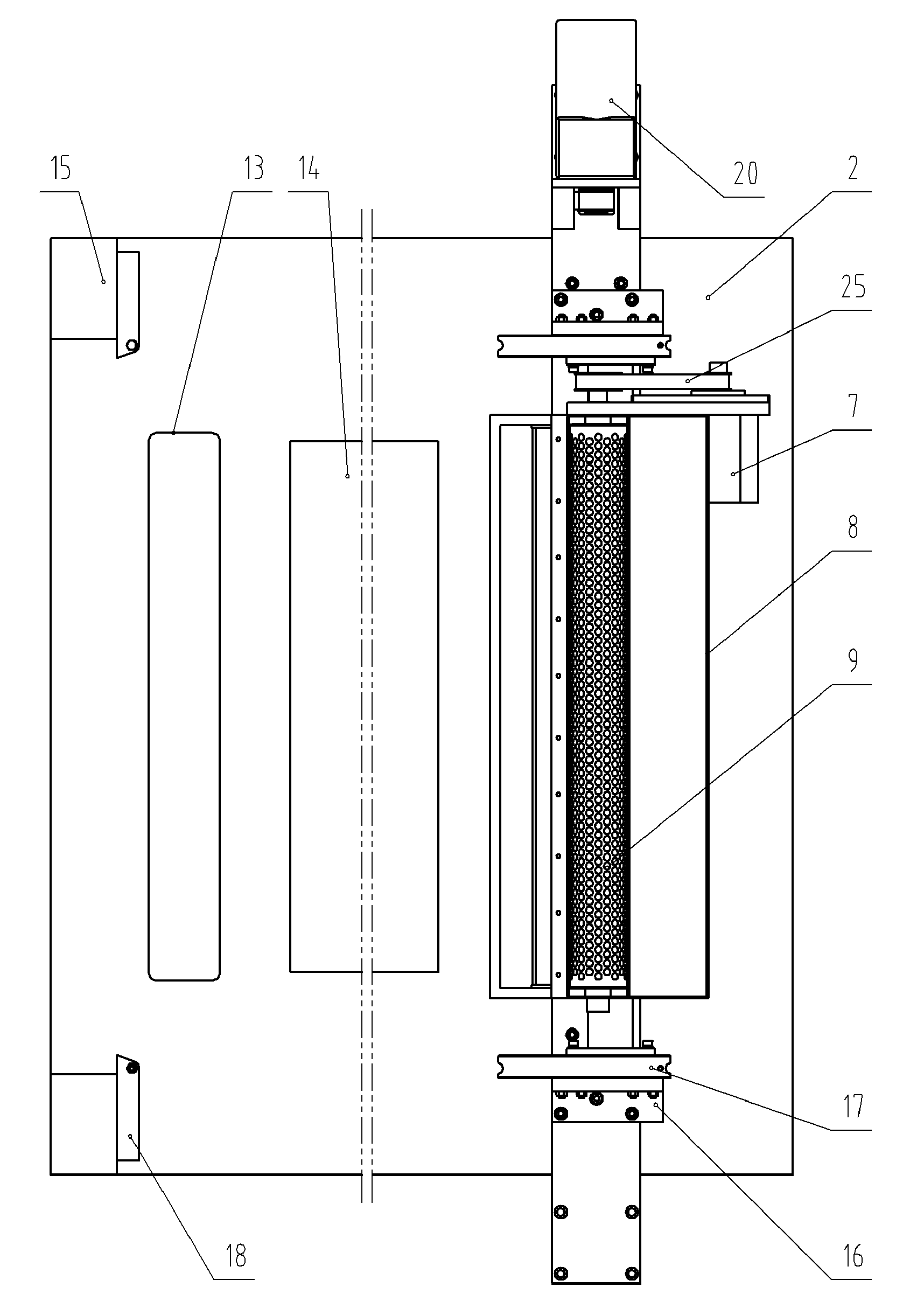

[0030] The front and rear sides of the workbench 2 are equipped with powder receiving buckets 1, 13, and the work plane 14 is arranged in the central area of the workbench. The work plane 14 can move up and down relative to the workbench 2. The powder pressing roller 3 of the powder device is installed under the connecting plate 4 through the powder pressing roller support 22, one end of the powder pressing roller 3 is connected with the powder pressing motor 20 through the belt pulley assembly 21, and the surface of the powder pressing roller 3 is chrome-plated to To increase its wear resistance, the powder spreading funnel 12 is fixed on the connecting plate 4, and an adjusting backing plate 5 is also provided between the powder spreading funnel 12 and the connecting plate 4, so that the distance between the powder spreading funnel 12 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com