Metal sheet molding die

A metal sheet, forming mold technology, applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of high mold cost, high mold precision, complex processing, etc., to achieve low mold manufacturing cost, smooth and round surface, use handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

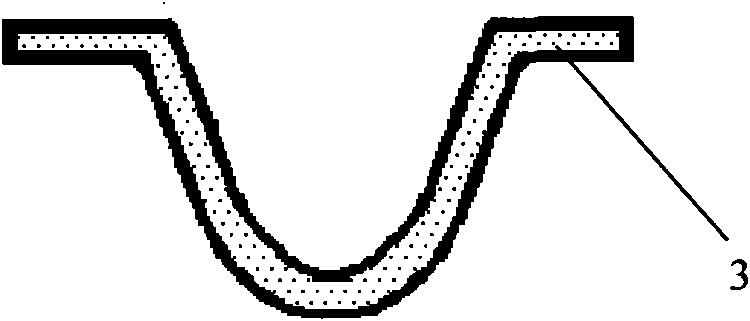

[0016] Such as figure 1 Shown is a schematic diagram of a 3-diameter cross-section of a metal sheet.

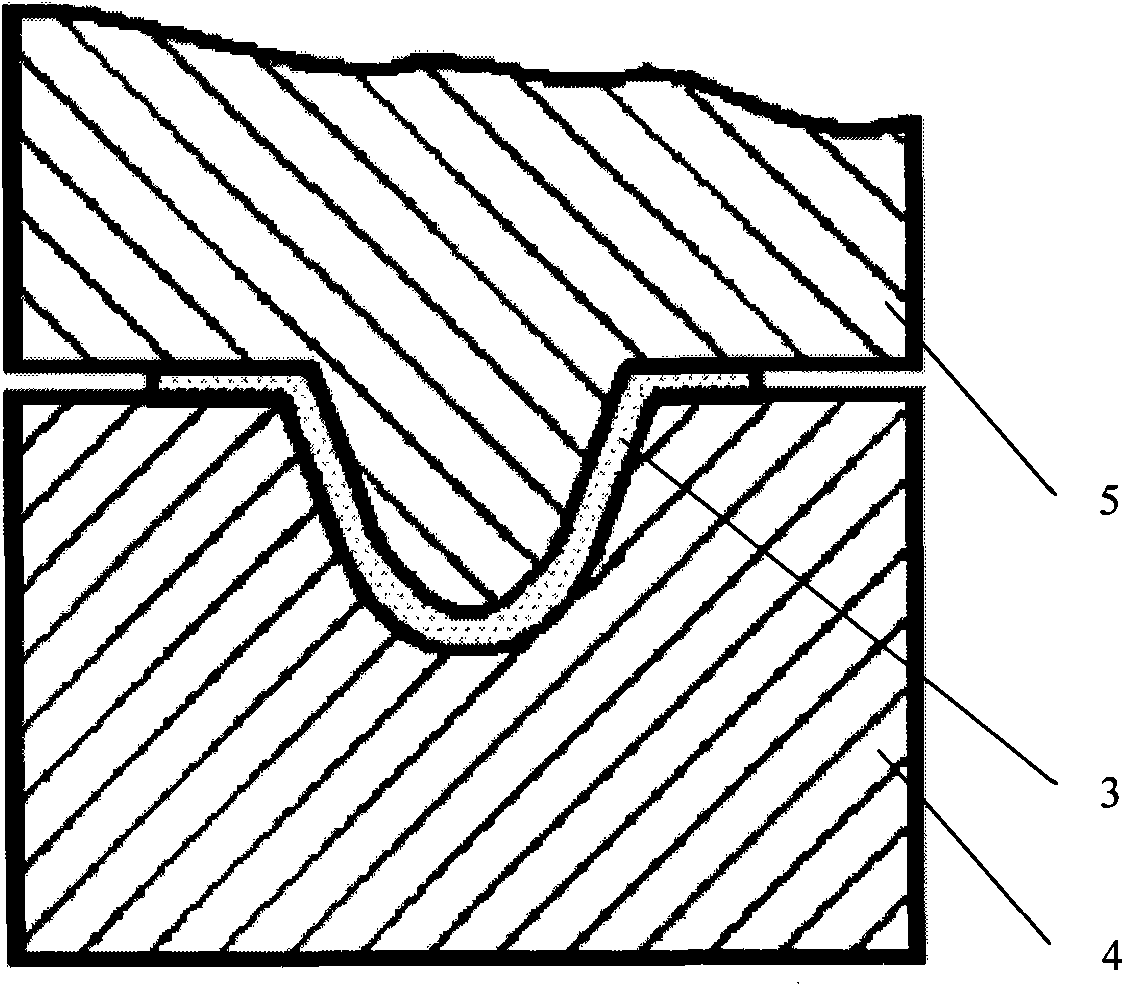

[0017] figure 2 Shown is the mold processing diameter section of adopting prior art such as figure 1 The schematic diagram of shown metal sheet 3, this mold comprises die 4 and punch 5, the concave surface of die 4 and the protruding surface shape of metal sheet 3 aperture section, size are consistent, the convex face of punch 5 and metal sheet The shape and size of the concave surface of the 3-diameter cross-section are consistent. When the mold is processed, the dimensions of the die 4 and the punch 5 must be matched very accurately, and the processing is difficult; at the same time, when the protruding part of the metal sheet 3 is When the U-shaped ring is in shape, it is more difficult to guarantee the processing of the mold; and duri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com