Method for fixing gangue dumping platform in process of using permanent derrick to construct well

A fixing method and derrick technology, applied to drilling equipment, earthwork drilling, supporting devices, etc., can solve the problems of high technical requirements, small usable area of the platform, large amount of recovery, etc., and achieve the effect of expanding the usable area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

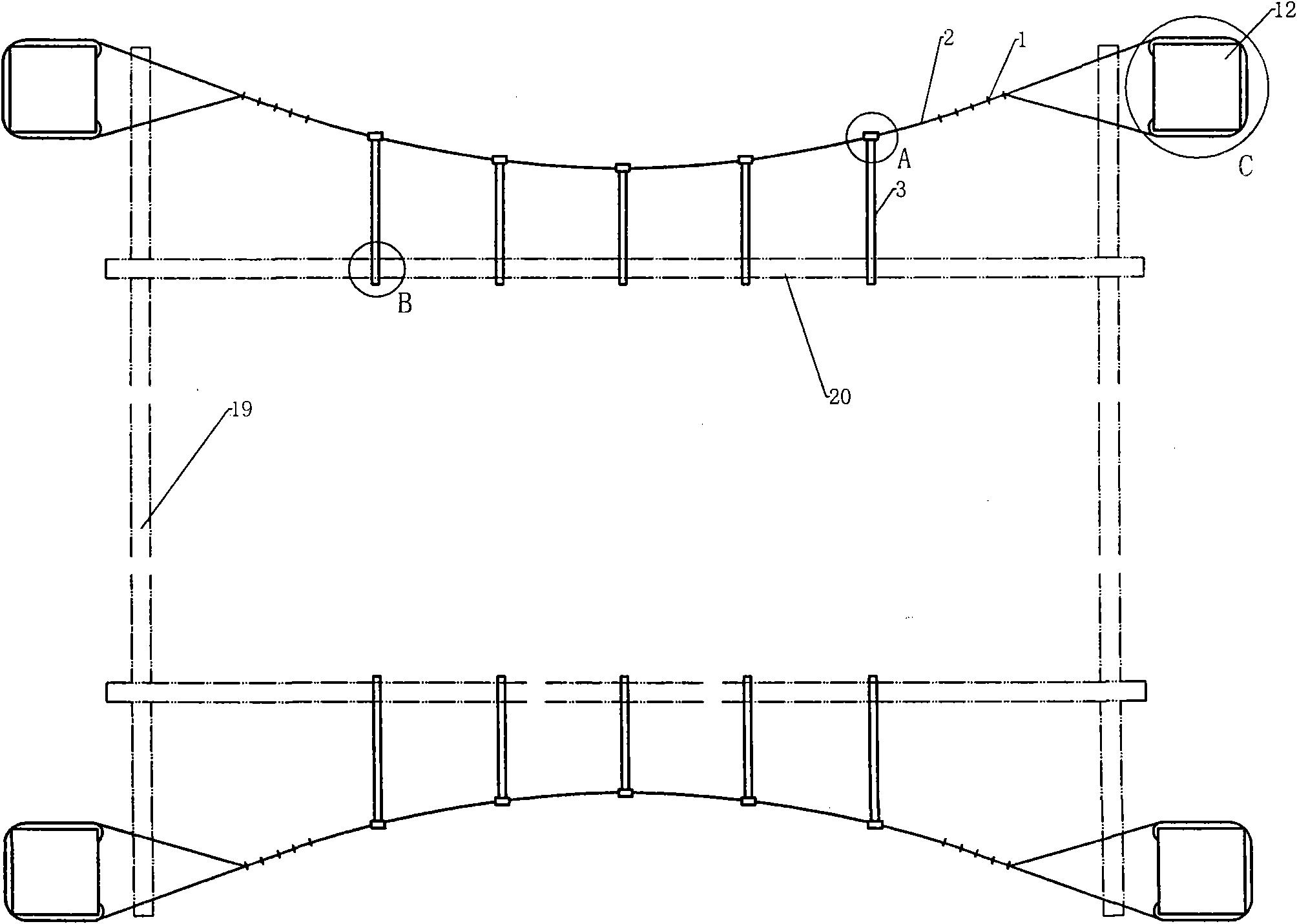

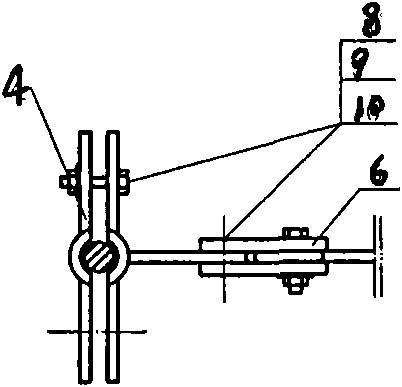

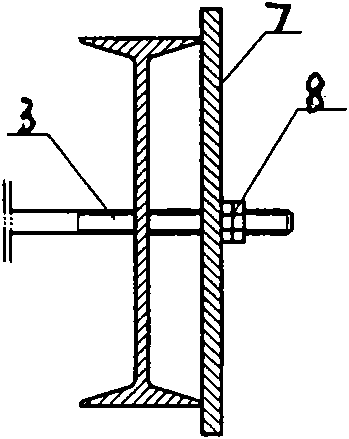

[0014] like Figure 1-Figure 6 As shown, the gangue turning platform is set at the appropriate height of the permanent derrick. The height of the turning gangue platform is determined according to the needs of the site. The corbels 18 are respectively fixed with bolts on each derrick leg 12 of the permanent derrick. The bolt specifications, quantity and design of the corbels are calculated according to depends. Two steel beams are installed on the corbel, that is, steel beam A19. The steel beam section is selected as the objective function. The force of the steel beam is mainly to bear the horizontal load, and the vertical load only considers the initial plane load of the platform before the suspender is set up. Taking the center line of the wellbore as the benchmark, two steel beams, namely steel beam B20, are symmetrically arranged on the steel beam A19. The above structure forms a platform frame, and then a certain number of small beams are supplemented according to the wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com