Mechanical equipment for collection of pulp fiber and separation of water, ink and sludge

A technology of pulp fiber and mechanical equipment, applied in the field of mechanical equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

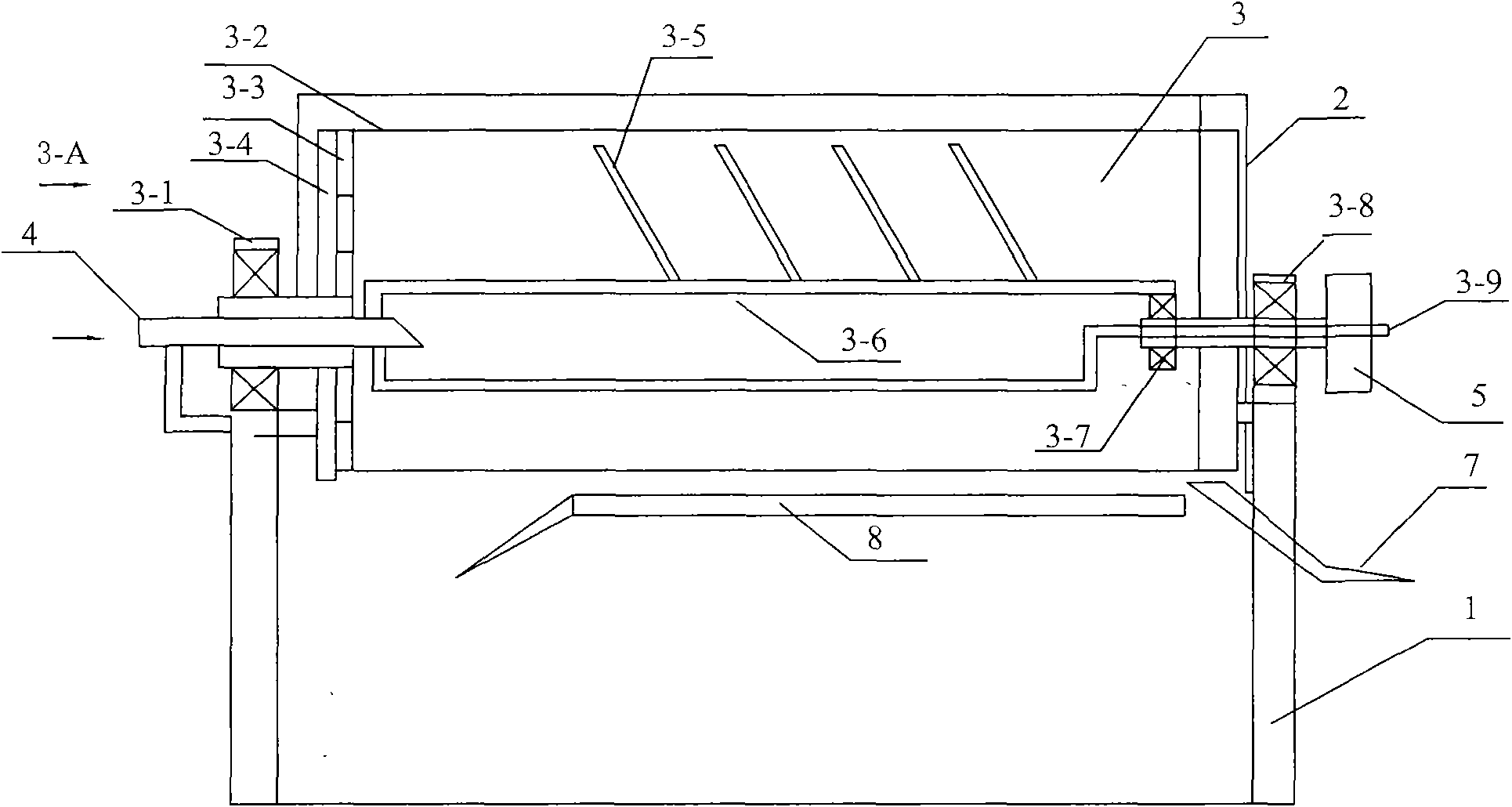

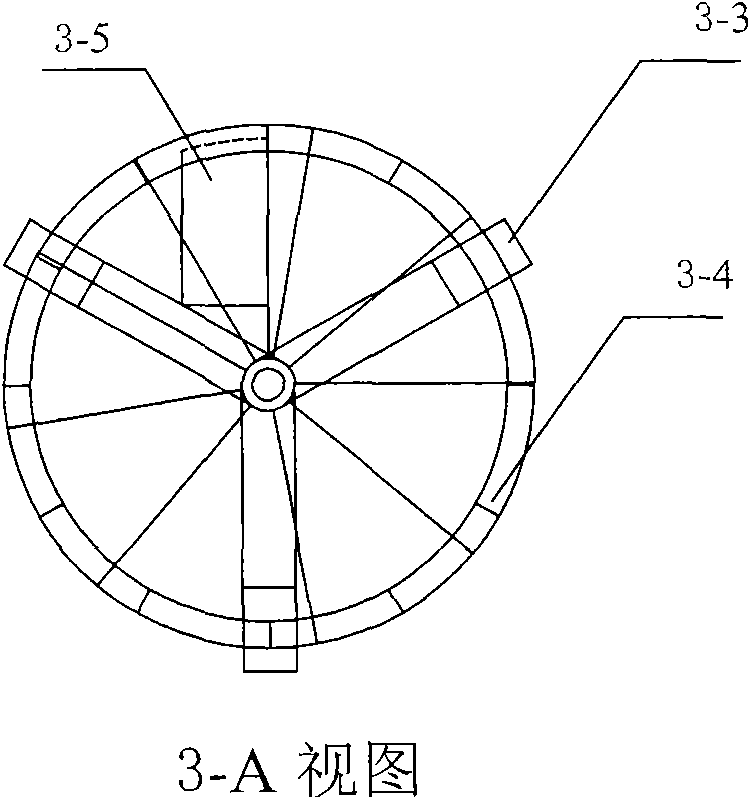

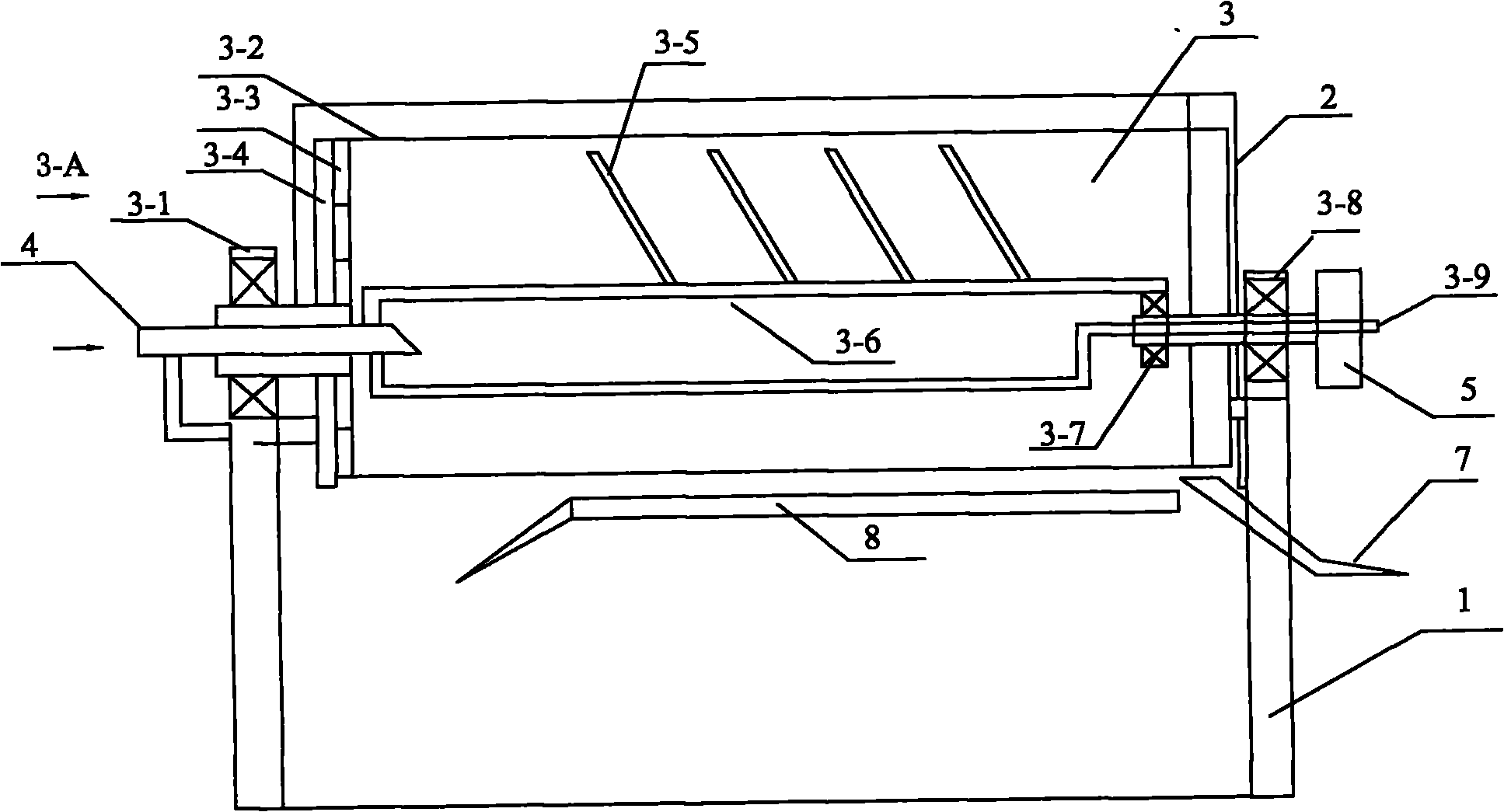

[0008] As shown in the figure: the present invention relates to a mechanical device for collecting pulp fibers and separating water, ink and sludge.

[0009] Including the frame 1, in order to prevent the paddle, water, ink, and sludge from splashing, a protective cover 2 is installed on the frame, so that the paddle inlet pipe 4 can enter the paddle separation barrel 3, we will connect the paddle The shaft of the separation barrel 3 is made into a hollow shaft, and is fixed on the frame 1 through the bearing 3-1 and the bearing seat, and the pulp inlet pipe 4 enters the pulp separation barrel 3 through the hollow shaft of the pulp separation barrel, and The pulp inlet pipe 4 is fixed on the frame 1, when the chemically treated pulp enters the pulp separation barrel 3 from the inlet pipe 4. A screen 3-2 with a mesh size of 0.5-1 mm is installed on the surface of the pulp separation barrel 3 , and the actual installation length of the screen mesh of the pulp separation barrel i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com