Copper matte processing method and device thereof

A processing method and processing equipment technology, applied in the field of copper matte, can solve problems such as poor operating environment, high construction costs, and large equipment investment, and achieve the effects of simple structure, low equipment investment, and high batching accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

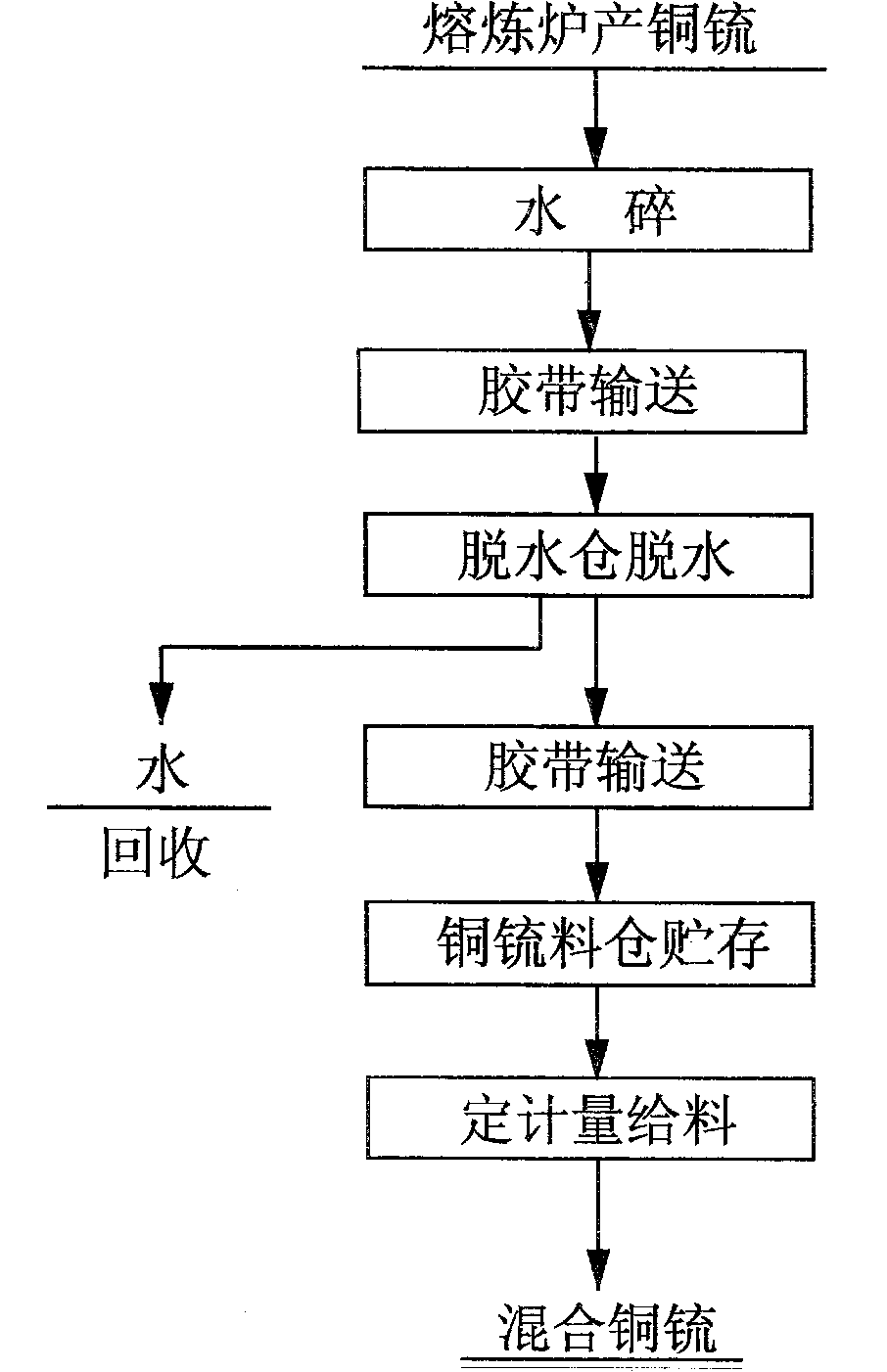

[0035] The present invention will be further described below with reference to the accompanying drawings and in conjunction with specific embodiments.

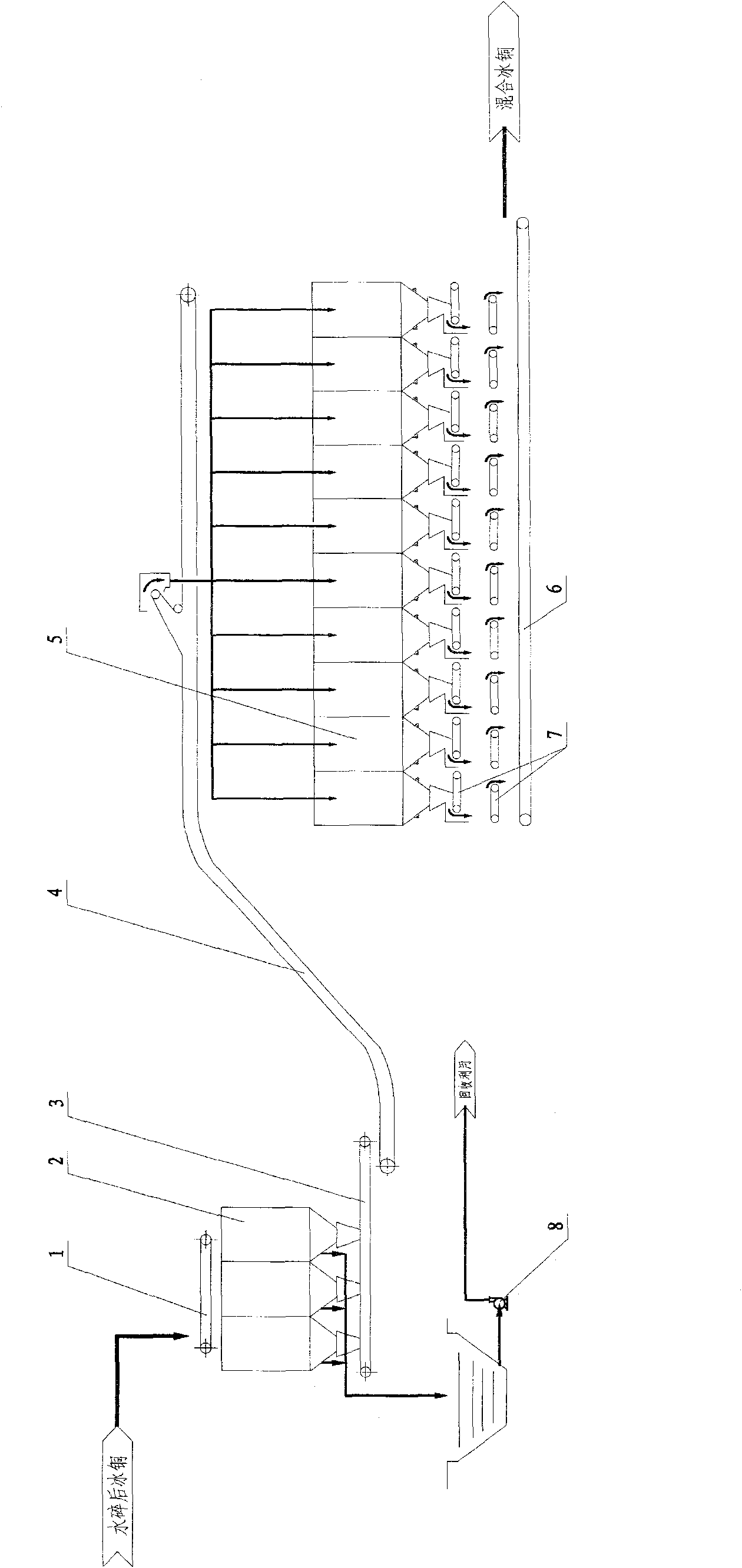

[0036] A copper matte treatment equipment for copper continuous blowing process with fluctuating raw material composition, including three volumes of 70m 3 The bottom of is provided with the dehydration bin 2 of dehydrator, ten storage bins 5 and the belt conveyor that is arranged between dehydration bin 2 and storage bin 3, all is existing equipment.

[0037] The belt conveyor includes a reversible belt 1, a transfer belt 3, a storage bin top unloading belt 4, a mixed copper matte conveying belt 6 and a fixed metering feeding belt 7, and the fixed metering feeding belt 7 is arranged on each storage bin 5 for discharging The running speed of the constant metering tape is 0.1-0.5m / s, controlled by the computer control system to control the copper matte feeding amount of each storage bin 5 respectively.

[0038] The ten storage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com