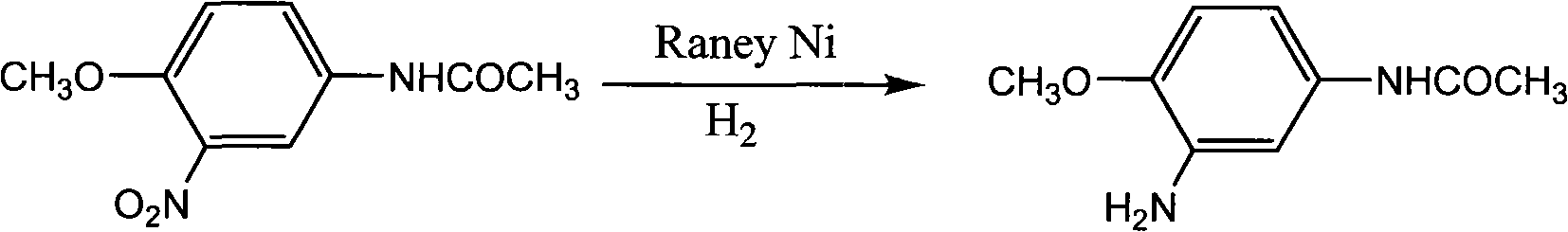

Method for preparing 3-amino-4-methoxyacetanilide by taking Raney nickel as catalyst

A technology of methoxyacetanilide and Raney nickel, which is applied in the direction of Raney catalysts, chemical instruments and methods, and the preparation of organic compounds, can solve environmental pollution and other problems, and achieve a green reaction process, high catalyst activity, Effect of high feedstock conversion and product selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Add the Ni-Al alloy with a mass ratio of 1:1 to 150mL of 20wt.% sodium hydroxide solution at 50°C within 5min, heat to 80°C after the addition, and keep it at 80°C for 90min, the whole process maintains Stirring state. After the reaction, cool down, filter, wash the filter cake with ethanol three times and then wash with distilled water until pH = 7, and finally store the prepared Raney nickel in absolute ethanol for future use. Weigh 1.0 g of the Raney nickel catalyst prepared above, 10 g of 3-nitro-4-methoxyacetanilide, that is, the mass ratio of the catalyst to the raw material is 1:10, add them to a 1000 mL reactor, add 200 mL of methanol, and start Stir. Nitrogen was introduced for 10 minutes to fully replace the oxygen in the reactor, and hydrogen was added to make the pressure 0.8MPa. Then, gradually raise the temperature to 80°C and react for 2h. After the reaction, the reactor was cooled to about 30°C, and samples were taken for liquid chromatography detecti...

Embodiment 2

[0019] Add the Ni-Al alloy with a mass ratio of 1:2 to 150mL of 20wt.% sodium hydroxide solution at 50°C within 20min, heat it to 80°C after the addition, and keep it at 80°C for 120min, the whole process maintains Stirring state. After the reaction, cool down, filter, wash the filter cake with ethanol three times and then wash with distilled water until pH = 7, and finally store the prepared Raney nickel in absolute ethanol for future use. Weigh 1.0 g of the Raney nickel catalyst prepared above, 10 g of 3-nitro-4-methoxyacetanilide, that is, the mass ratio of the catalyst to the raw material is 1:10, add them to a 1000 mL reactor, add 200 mL of methanol, and start Stir. Nitrogen was introduced for 10 minutes to fully replace the oxygen in the reactor, and hydrogen was added to make the pressure 2.0 MPa. Then, gradually raise the temperature to 100°C and react for 2h. After the reaction, the reactor was cooled to about 30°C, and samples were taken for liquid chromatography ...

Embodiment 3

[0021] Add the Ni-Al alloy with a mass ratio of 1:4 to 150mL of 20wt.% sodium hydroxide solution at 50°C within 5min, heat to 80°C after the addition, and keep it at 80°C for 100min, the whole process maintains Stirring state. After the reaction, cool down, filter, wash the filter cake with ethanol three times and then wash with distilled water until pH = 7, and finally store the prepared Raney nickel in absolute ethanol for future use. Weigh 1.0 g of the Raney nickel catalyst prepared above, 10 g of 3-nitro-4-methoxyacetanilide, that is, the mass ratio of the catalyst to the raw material is 1:10, add them to a 1000 mL reactor, add 200 mL of methanol, and start Stir. Nitrogen was introduced for 10 minutes to fully replace the oxygen in the reactor, and hydrogen was added to make the pressure 1.5 MPa. Then, gradually raise the temperature to 110°C, and react for 2h. After the reaction, the reactor was cooled to about 30°C, and samples were taken for liquid chromatography det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com