Rice seed turning and mixing system

A technology for rice seeds and turning mixing, applied in mixers, mixing methods, fluid mixers, etc., can solve the problems of difficult to achieve uniform mixing, uneven seed quality, serious dust pollution, etc., and achieve uniform seed quality and mixing. Good effect and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

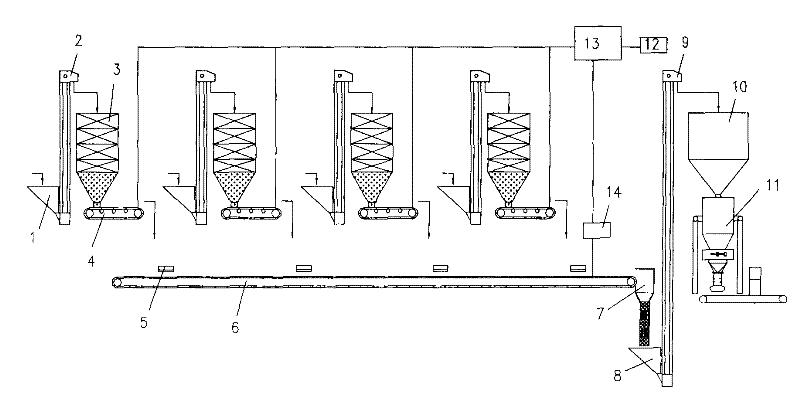

[0019] The rice seed mixing system of the present invention is as figure 1 As shown, it includes a number of feeding hoppers 1 arranged sequentially from left to right, and the feeding hoppers 1 are mounted on the No. On the material side, a belt scale 4 is provided below the discharge port of the storage bin 3, and the belt scale 4 corresponds to the deflector 5 arranged on the upper surface of the stratified conveyor 6 one by one, and the discharge end of the stratified conveyor 6 Connect the feed port of the mixer 7, the outlet of the mixer 7 is set above the lifting bucket 8, the lifting bucket 8 is mounted on the No. On the loading side, the discharge port of the temporary storage bin 10 is connected to the feed port of the measuring and packaging scale 11 .

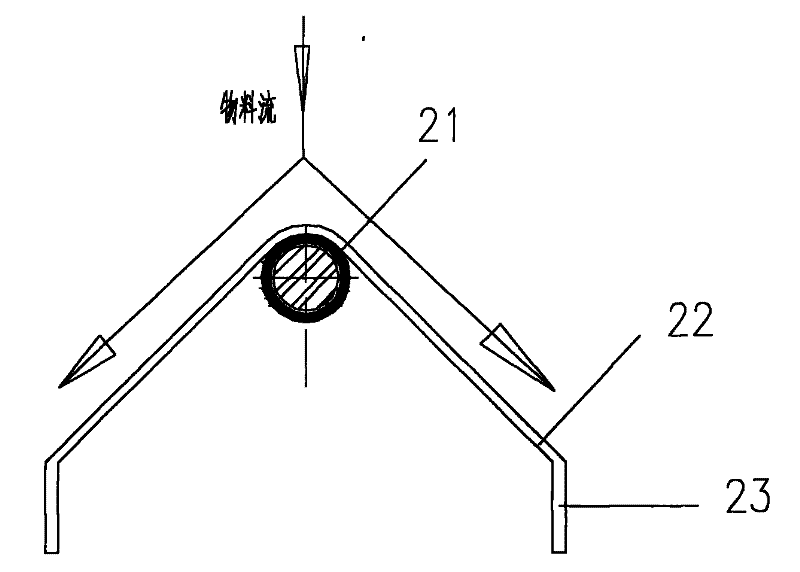

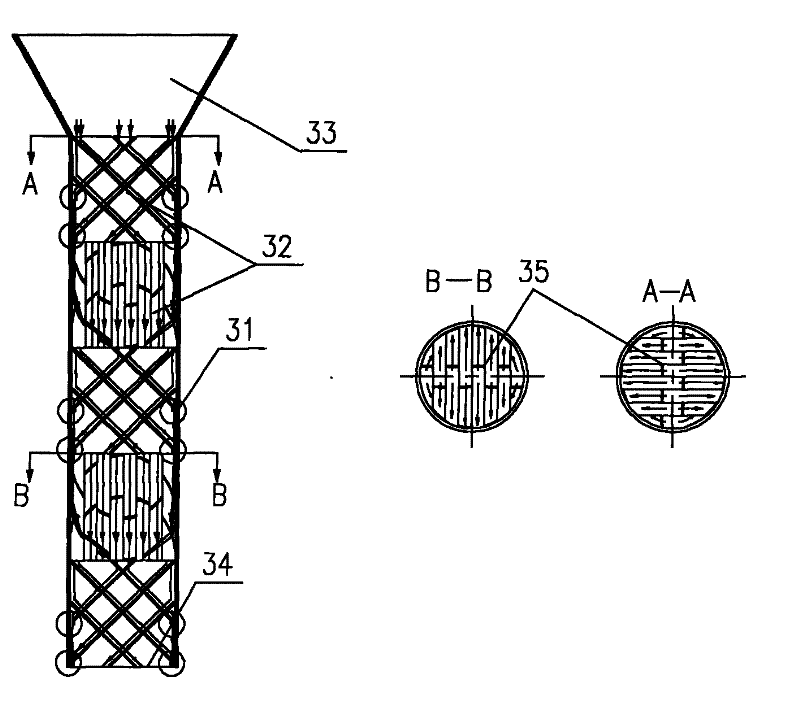

[0020] On the basis of the above technical solution, ribs are provided on both sides of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com