Marine engineering large thick steel plate submerged arc welding process method in low-temperature environment

A process method, marine engineering technology, applied in arc welding equipment, welding media, manufacturing tools, etc., can solve problems such as increasing production costs, and achieve the effect of reducing labor intensity, reducing costs, huge economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

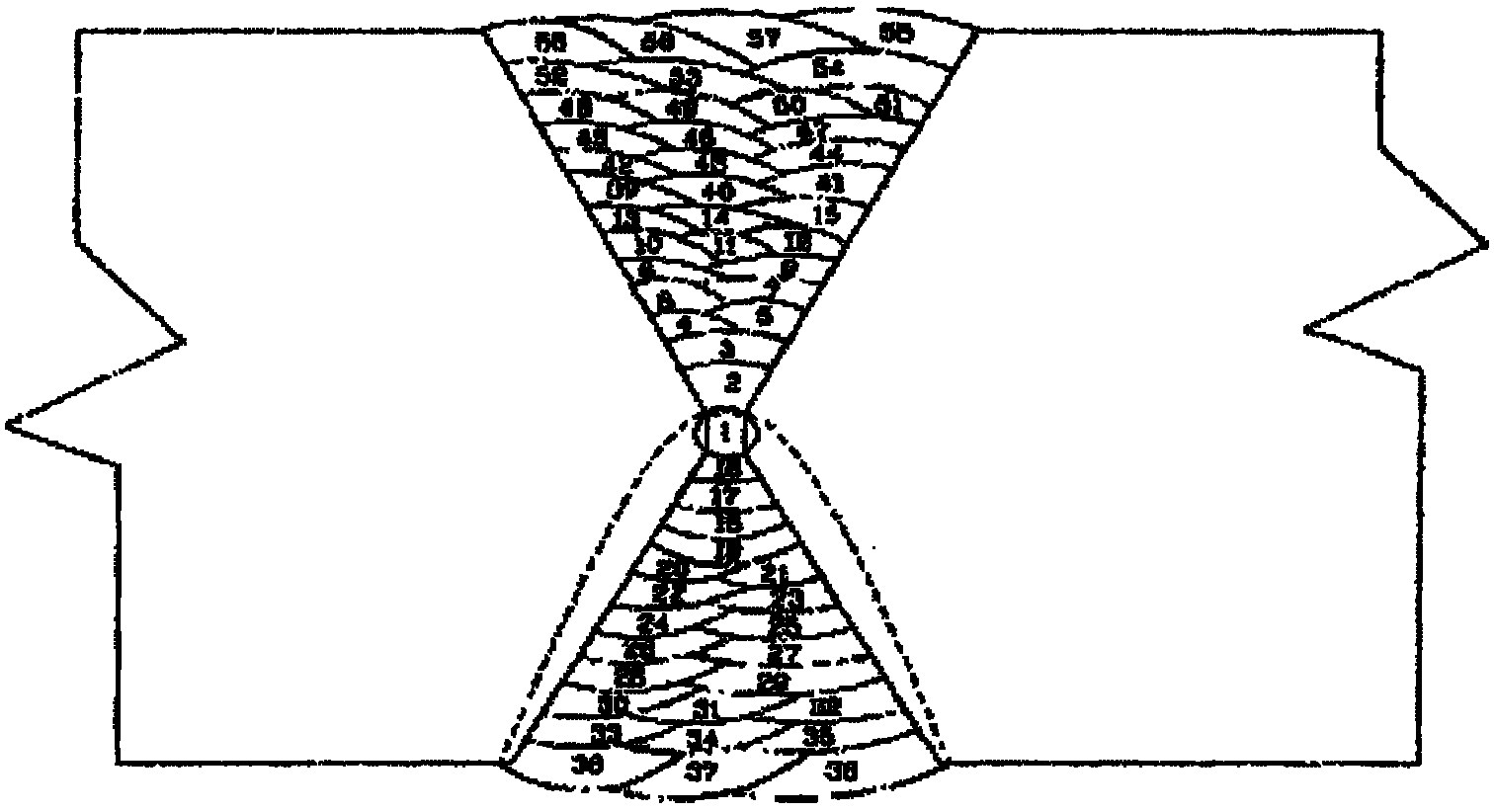

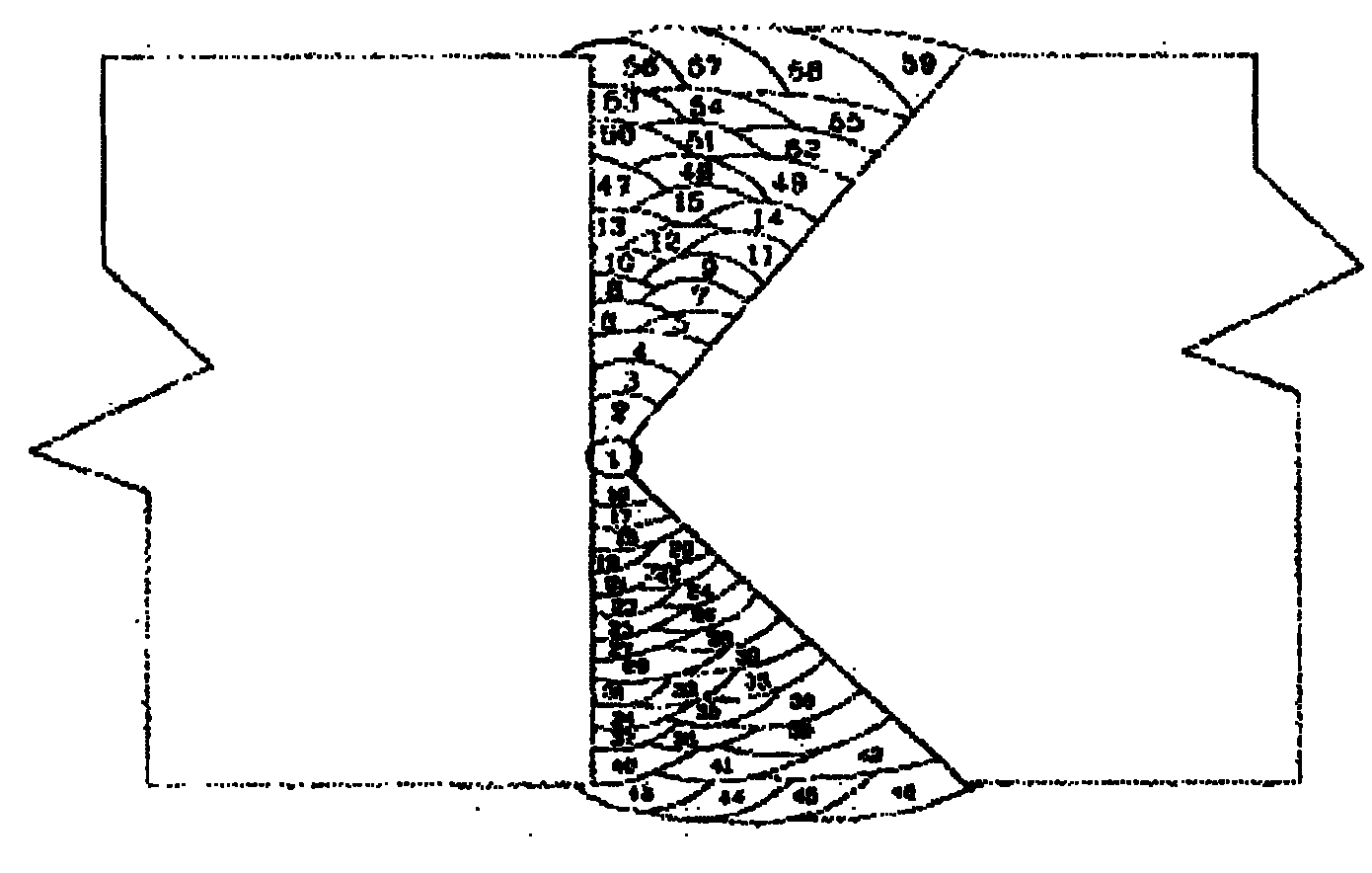

[0024] Embodiment: refer to attached Figure 1-Figure 5 In this process, the base material is 70mm thick E36 steel plate, X-type and K-type grooves are selected for welding, carbon dioxide gas shielded welding is used for backing, and submerged arc automatic welding is used for filling and covering. Stop after reaching two-thirds of the thickness of the large groove, carry out back cleaning and start welding on the other side, complete the small groove weld, and then complete the welding of the large groove surface; strictly control the interlayer temperature of the welding during the welding process , Strictly control welding voltage, current, welding speed and other parameters to obtain appropriate heat input.

[0025] The welding materials are LW-81Ni and Lincoln L-S3 (8500) produced by Lincoln Company of the United States, and the welding machine adopts the single-wire submerged arc welding machine of Lincoln Company of the United States. The welding consumables use flux-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com