High-frequency copper tube pulling-casting process

A copper tube and high-frequency technology, applied in the high-frequency drawing and casting process of copper tube processing, can solve the problems of unstable tensile strength of products, short life of graphite molds, and high unit power consumption of products, and achieve uniform and stable mechanical properties. , improve the service life, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

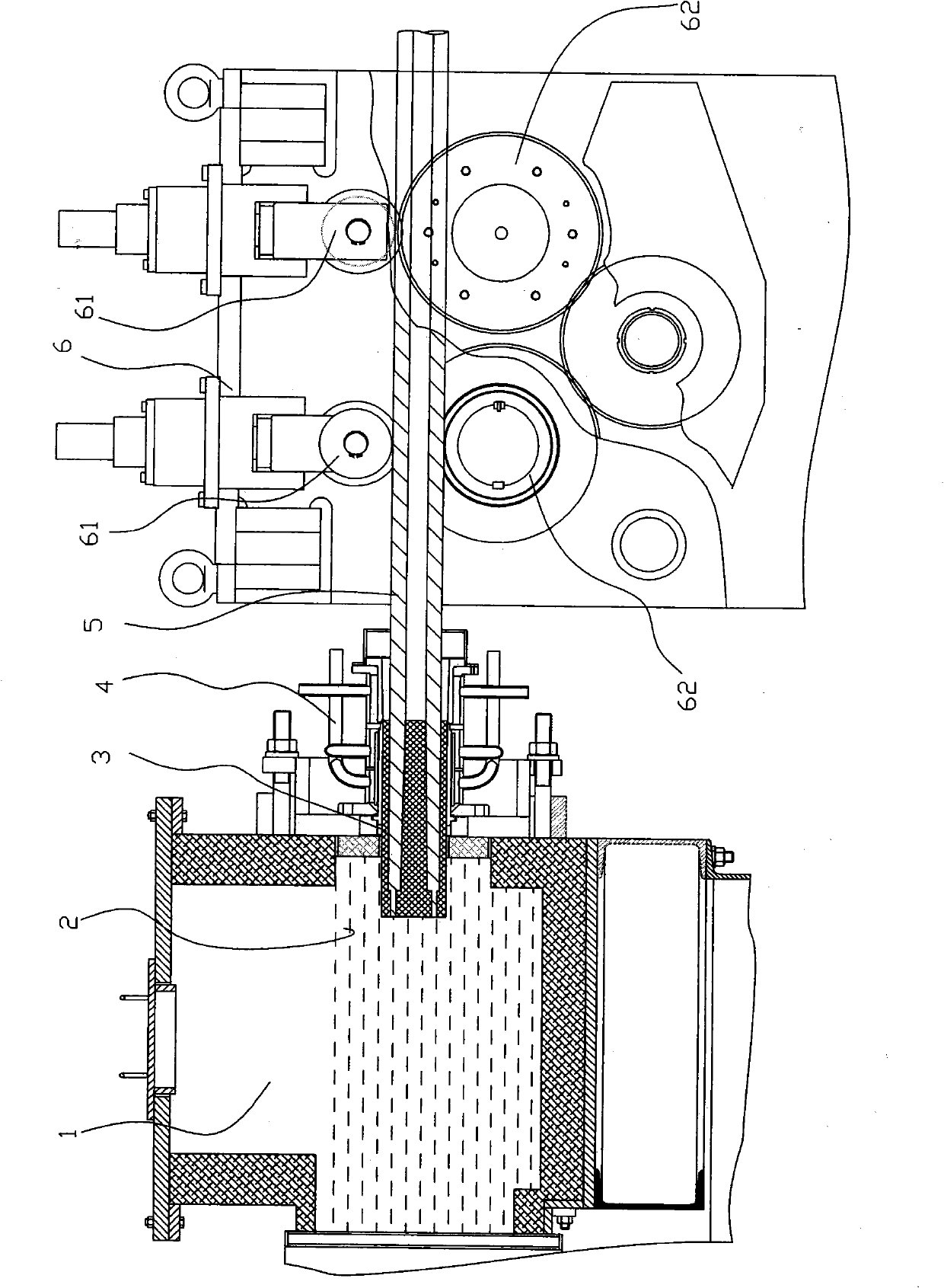

Image

Examples

Embodiment 1

[0011] Example 1: pull forward, speed 26.39mm / S, process 6mm—stop for 0.25 seconds—push backward, speed 22.99mm / S, retreat 0.89mm—stop for 0.3 seconds—and then move backward Push, speed 13.32mm / S, retreat 0.43mm—stop for 0.01 second, one process unit ends, and the cycle of the next process unit starts. The casting temperature is 1160°C, the mold cooling water pressure is 0.7MPa, and the cooling water flow rate is 22m 3 / h. The casting speed reaches 327mm / min.

Embodiment 2

[0012] Example 2: pull forward, speed 26.39mm / S, process 6mm—stop for 0.2 seconds—push backward, speed 22.99mm / S, retreat 0.89mm—stop for 0.3 seconds—and then move backward Push, speed 13.32mm / S, retreat 0.39mm—stop for 0.01 second, one process unit ends, and the cycle of the next process unit starts. The casting temperature is 1155°C, the mold cooling water pressure is 0.7MPa, and the cooling water flow rate is 25m 3 / h. The casting speed reaches 351mm / min.

Embodiment 3

[0013] Example 3: pull forward, speed 26.39mm / S, process 5.67mm—stop for 0.1 seconds—push backward, speed 22.99mm / S, retreat 0.89mm—stop for 0.3 seconds—go back Push back, speed 13.32mm / S, retreat 0.39mm—stop for 0.02 seconds, one process unit ends, and the cycle of the next process unit starts. The casting temperature is 1150°C, the mold cooling water pressure is 0.8MPa, and the cooling water flow rate is 26m 3 / h. The casting speed reaches 375mm / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com