Submersible servodrive system

A technology of dragging system and submersible oil, applied in the field of dragging system, can solve the problems of reducing oil production cost, system efficiency, low motor efficiency and power factor, unable to realize flexible control, etc., to achieve effective control, reduce operation cost, attenuation small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings, so that those skilled in the art can understand and easily implement the present invention.

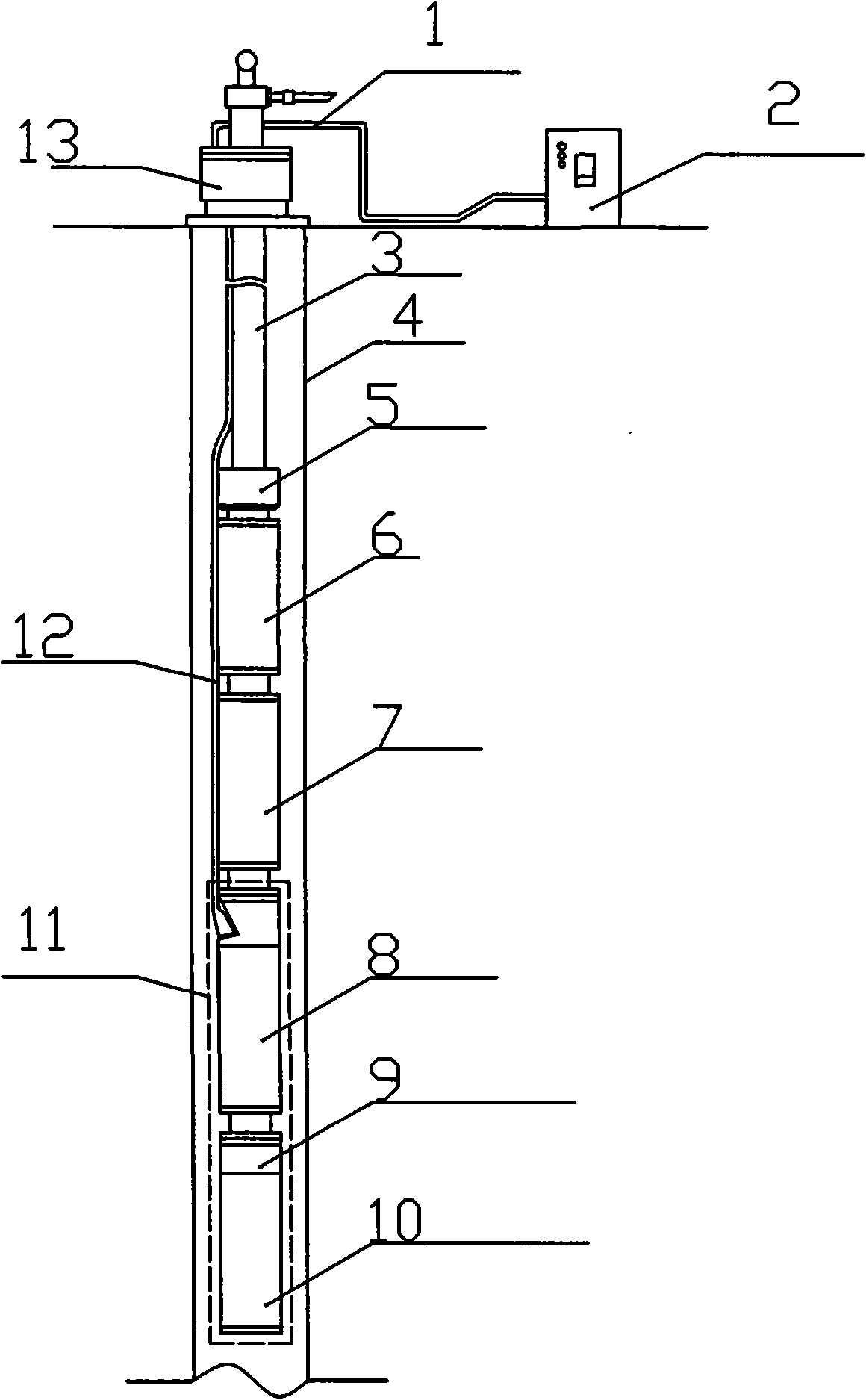

[0043] figure 1 It is a schematic diagram of the installation of the submersible servo pumping system. The submersible electric pump unit is generally placed more than 2,000 meters underground. The entire servo submersible electric pump unit is mainly composed of the ground control box 2, the submersible electric pump 6, the separator (not marked), the protector 7, and the submersible permanent magnet synchronous servo motor. The motor 8, the downhole servo control box, the leading cables 12, 1, etc. are composed, and each part is connected by connecting pieces such as relevant flanges. Other reference numerals represent: tubing 3 , casing 4 , outlet joint 5 , encoder and sealing assembly 9 , submersible servo system 11 and wellhead device 13 . figure 1 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com