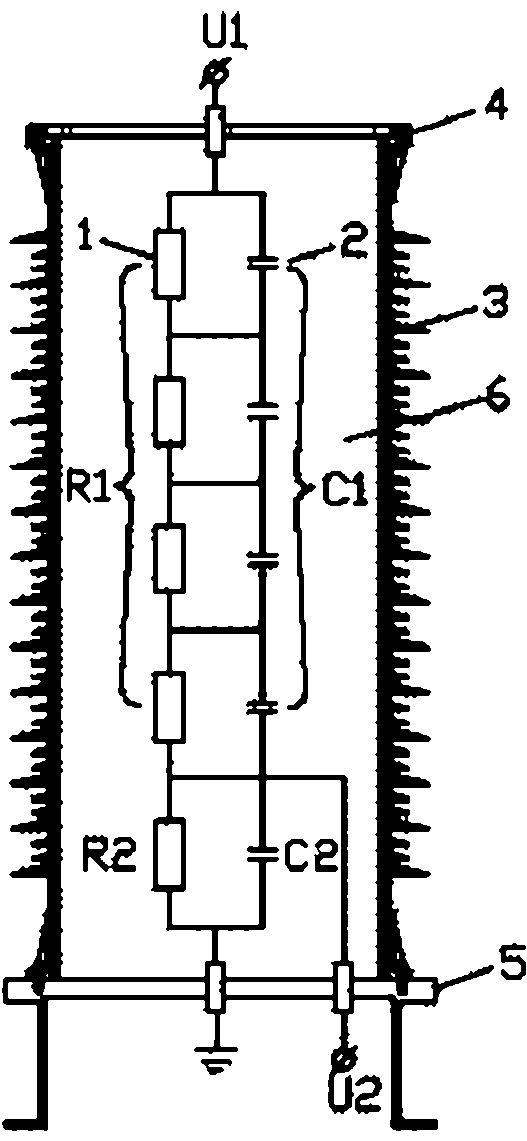

Method for improving pollution flicker-resisting capability of DC voltage transformer

A DC voltage and transformer technology, applied in the direction of inductors, transformers, circuits, etc., can solve the problems of easy breakdown and contamination on the external surface of the voltage transformer, and achieve the effect of improving the anti-pollution flickering ability and balancing the internal temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

[0029] 2. Example 2, using a multi-stage compartment structure to form multiple independent drying areas radially on the outer surface of the DC voltage transformer

[0030] In this instance (see Figure 5), inside the hollow insulator, the inner space of the insulator is divided into a number of relatively independent multi-level compartments 9 by insulating plates 8 from top to bottom, and the heating element resistance elements are evenly placed in each compartment. Since each compartment is relatively independent, the heat generated by the resistance of the heating element in each compartment gathers at the upper end of each compartment. Under humid environmental conditions, multiple relatively dry areas 10 are likely to appear on the outside of the hollow insulator. The hollow insulator corresponding to each compartment The outer side forms a state where the upper electric field distribution is strong and the lower electric field distribution is weak, so that the electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com