Carbon fiber upper pin assembly adopting pressure bars with combined structure and manufacturing method thereof

A combined structure and pressure bar technology, used in textiles and papermaking, drafting equipment, spinning machines, etc., can solve the complex surface cutting, grinding and electroplating processes, and the front jaws are prone to wear, damage, deformation, etc. The metal pressure bar is easy to absorb dust and other problems, so as to improve the quality of the yarn, avoid slack or slippery, and facilitate the connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

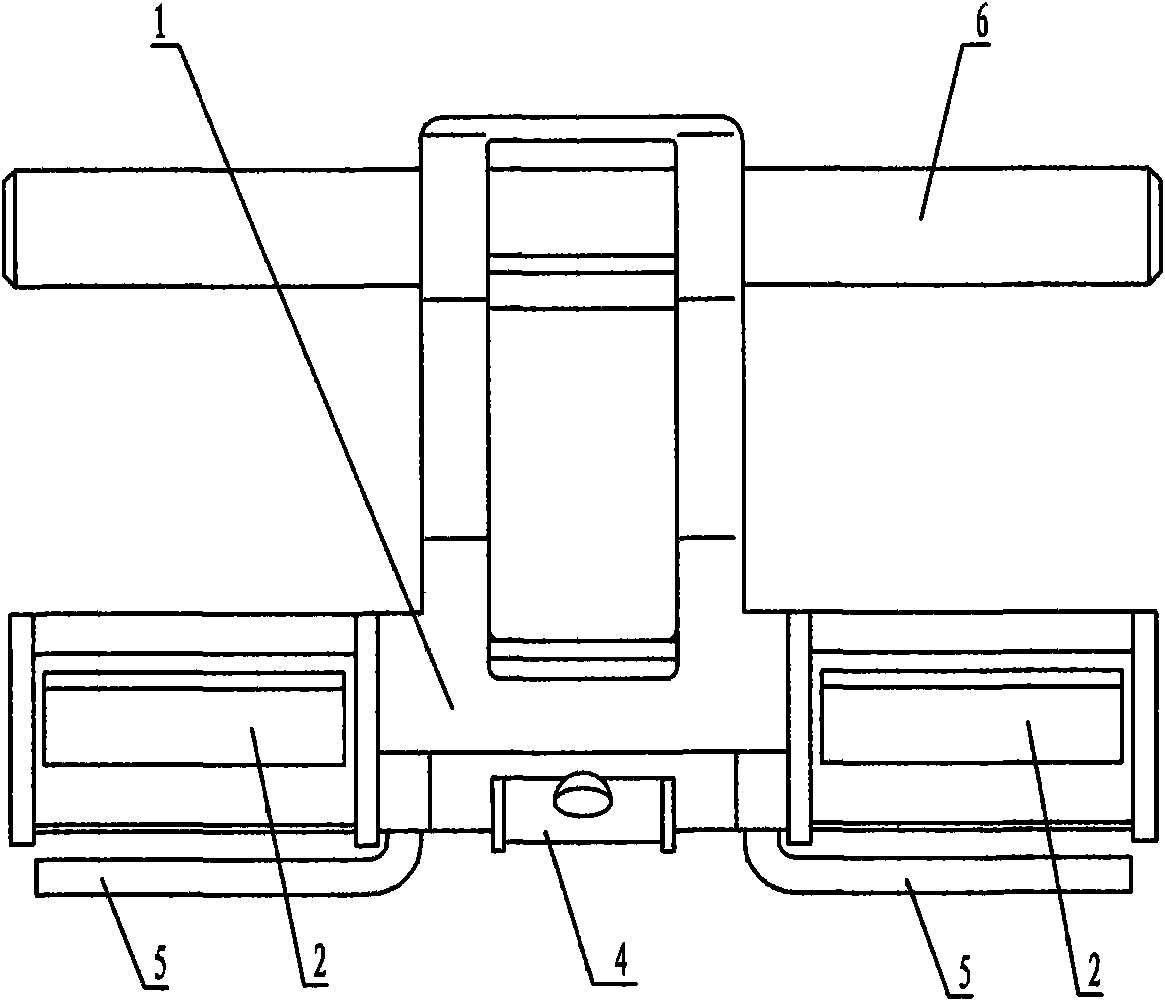

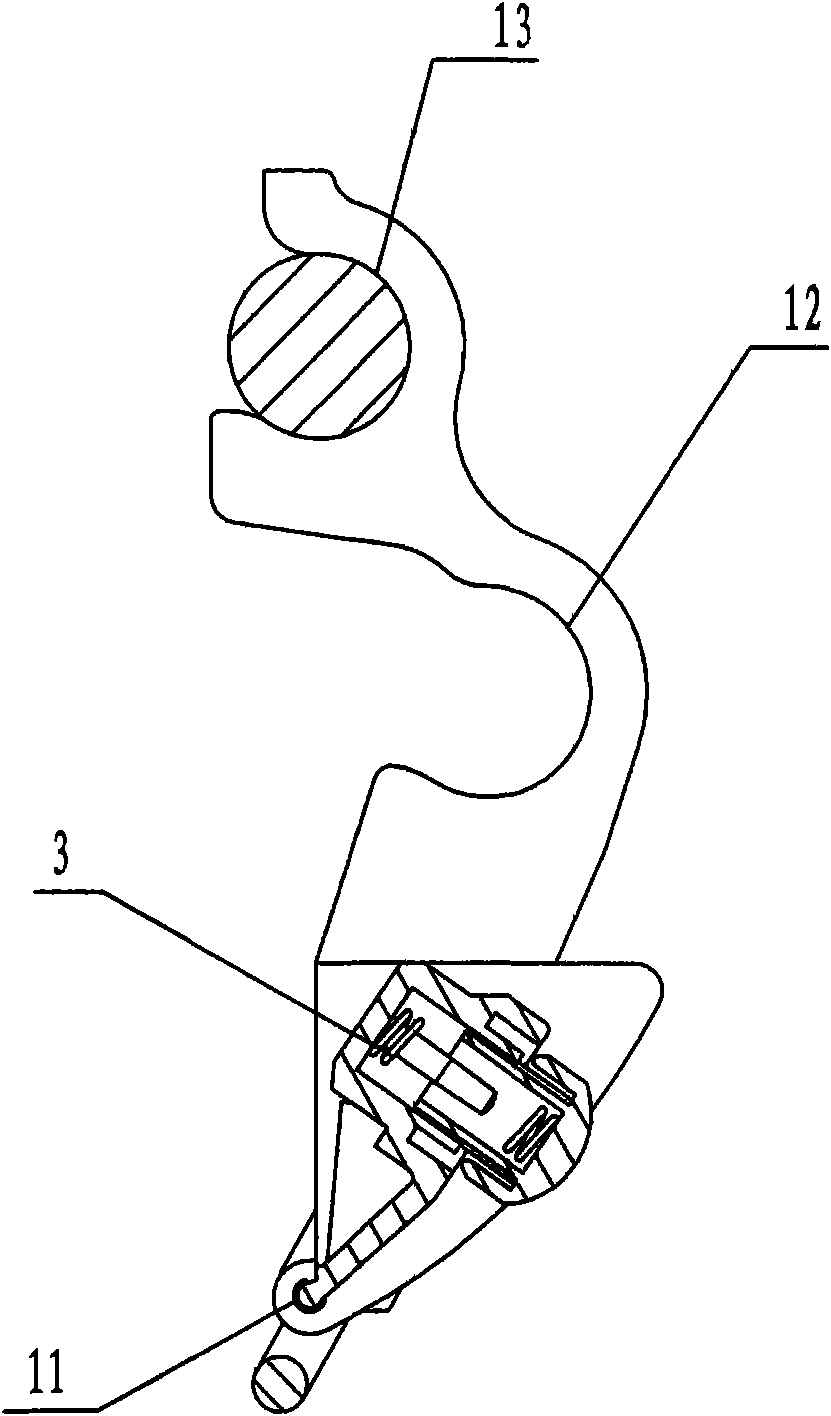

[0043] like Figure 1(A) , 1(B), 3-5(B), 7(A), and 7(B), a carbon fiber upper pin assembly adopting a combined structural pressure rod is a vertical tension elastic upper pin, including the upper pin frame main body 1, left 1. Right tensioning support plate 2, left and right telescopic spring 3, distance block 4, left and right pressure rods 5 in the front area, and 6 pressure rods in the rear area, which is a single rod type; the main body of the upper pin frame 1 includes the front left , the right jaw 11, the top roller bearing grip 12 and the clamping bayonet 13, the clamping bayonet 13 is located at the rear end of the top roller bearing grip 12, and is single-claw or double-claw; the front area is left and right The pressure bar 5 is 2 right-angled sides of a right-angled triangle, one side is long, and the other side is short, forming an angle of 90 degrees. The long side is in front of the front left and right jaws 11, parallel to the left and right jaws 11; the left...

Embodiment 2

[0052] like Figure 1(A) , 1(B) , 3, 4, 6 (A)-7 (B), a carbon fiber upper pin assembly using a combined structure pressure bar, the left and right jaws 11 at the front end of the upper pin frame main body 1 are left and right hoops, It is a metal needle 8, which is connected with the upper pin frame main body for injection and embedding. The rest are the same as embodiment 1.

Embodiment 3

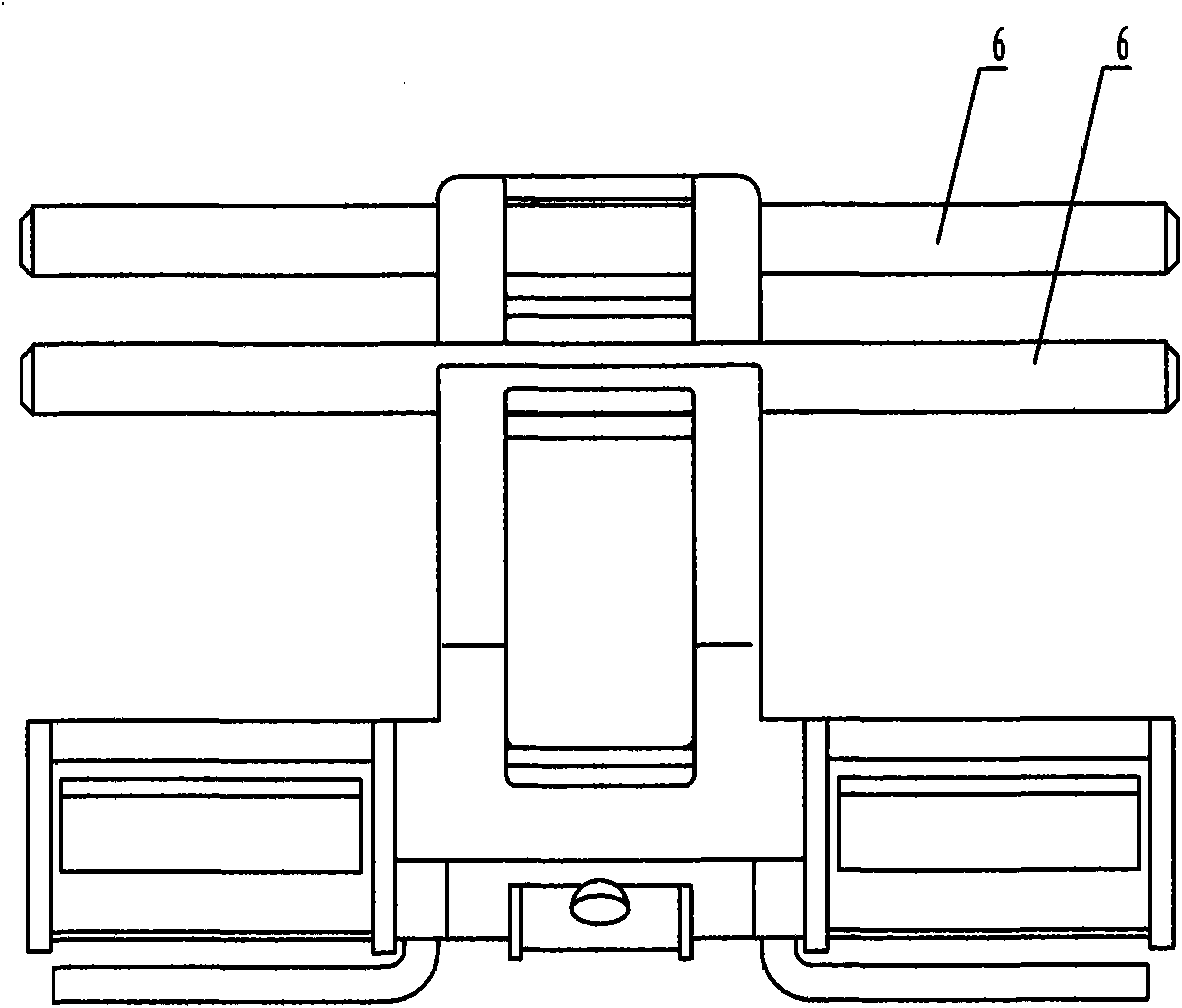

[0054] like Figure 2(A)-5(B) , 7(A), shown in 7(B), a carbon fiber upper pin assembly that adopts a combined structure pressure rod, and the rear area pressure rod 6 is 2 double rods, the rest is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com