Method for tracking moving object on production line

A moving target, production line technology, applied in image data processing, instrument, character and pattern recognition, etc., can solve the problems of difficult to meet the high-speed real-time requirements of production line robots, can not meet the needs, high computational complexity, and achieve real-time grasping of scattered motion Targets, avoid double-identified or missed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

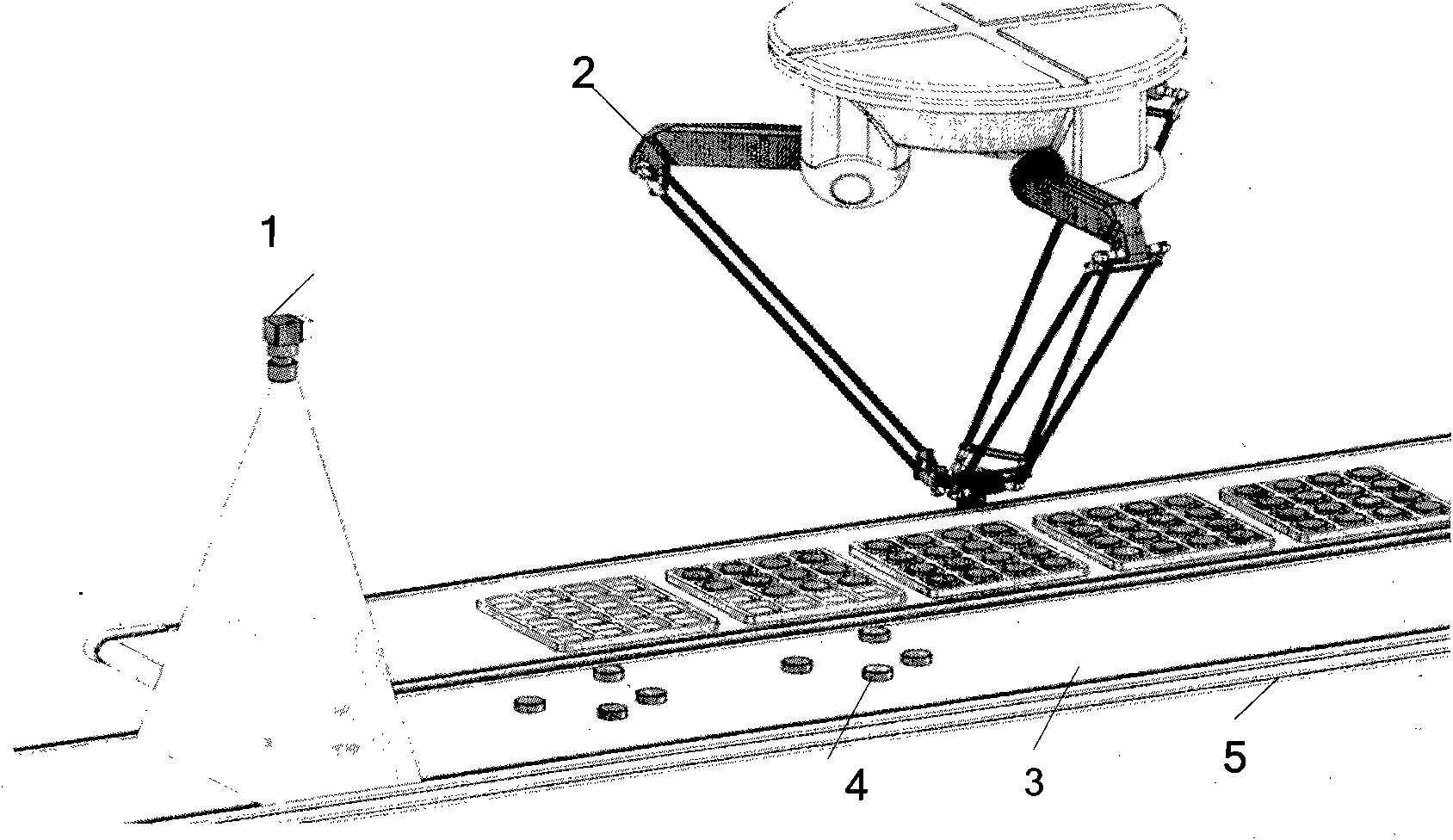

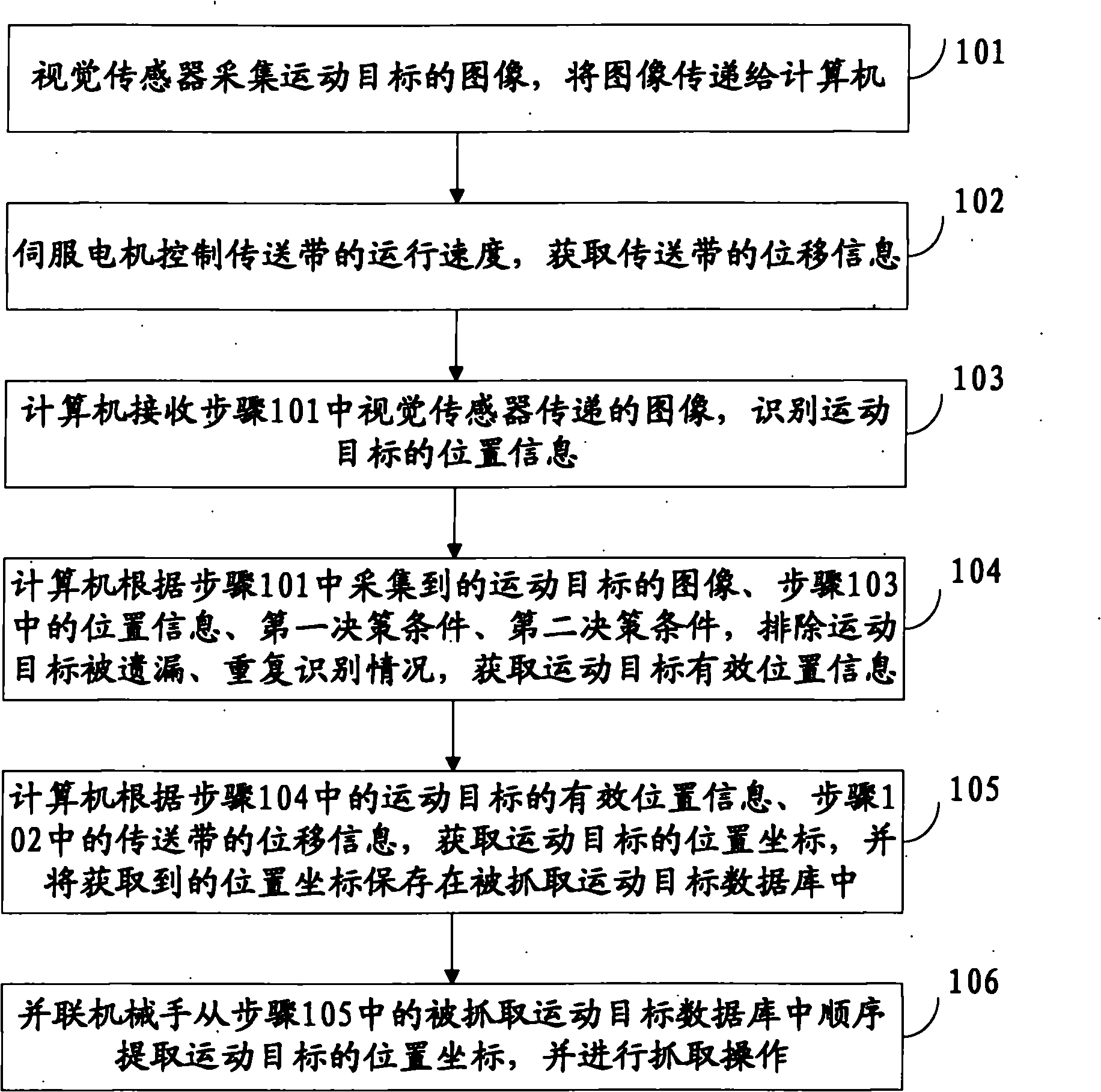

[0043] In order to meet the high-speed and real-time requirements for the production line robot to grab the moving target, the embodiment of the present invention provides a method for tracking the moving target on the production line, see figure 1 , figure 2 , the content of the method is as follows:

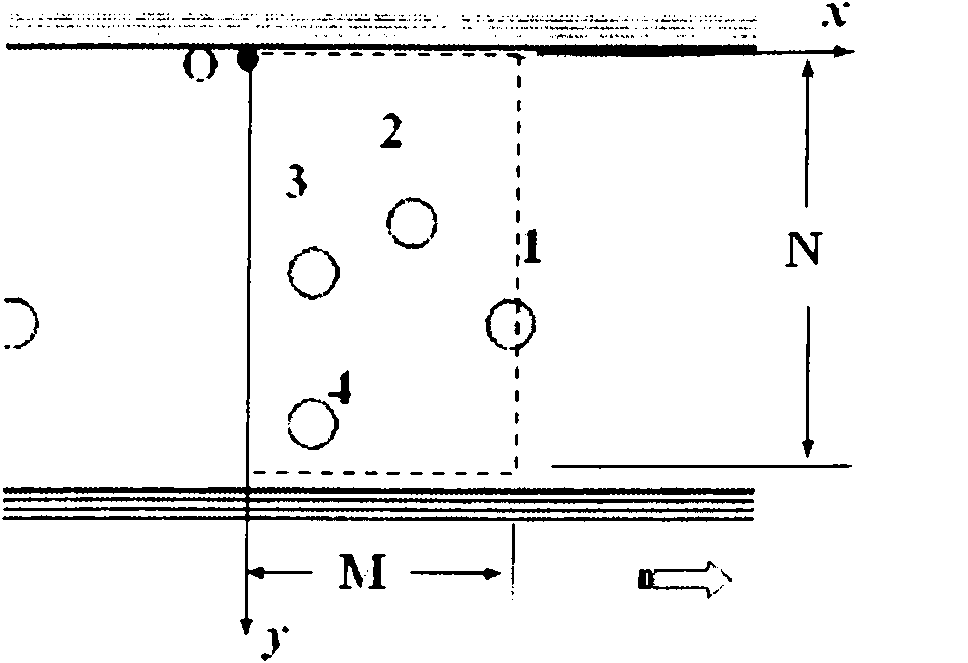

[0044] figure 1 Including: visual sensor 1, parallel manipulator 2, conveyor belt 3, several moving targets 4, servo motor 5. The visual sensor 1 and the parallel manipulator 2 are arranged above the conveyor belt 3 , and several moving objects 4 are scattered on the conveyor belt 3 and move in the direction of the parallel manipulator 2 along with the conveyor belt 3 .

[0045] Two-way feedback control is formed between the servo mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com