Magnetic check valve

A check valve and magnetic technology, applied in the field of magnetic check valve, can solve the problems of inability to be directly applied, unable to guarantee the automatic re-suction of the valve plate and the valve core, small suction force, etc., to achieve low cost, stable and good guiding effect, The effect of good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

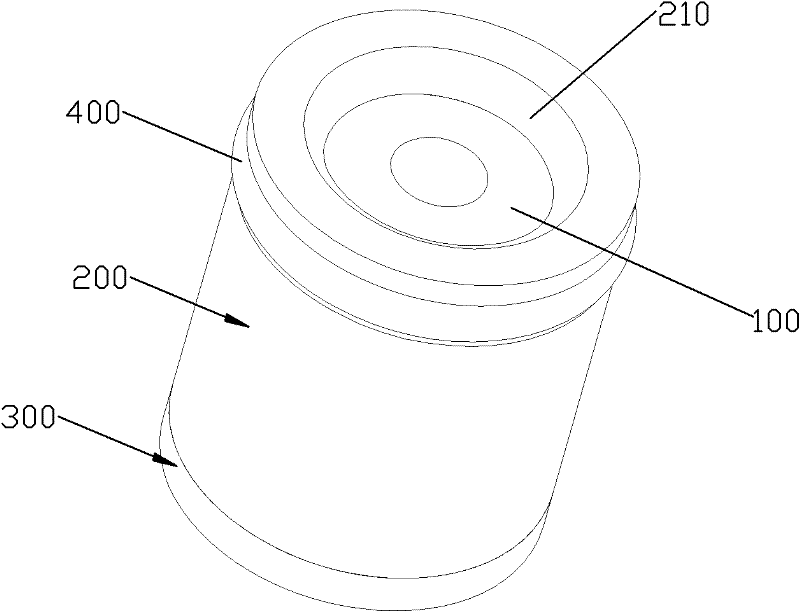

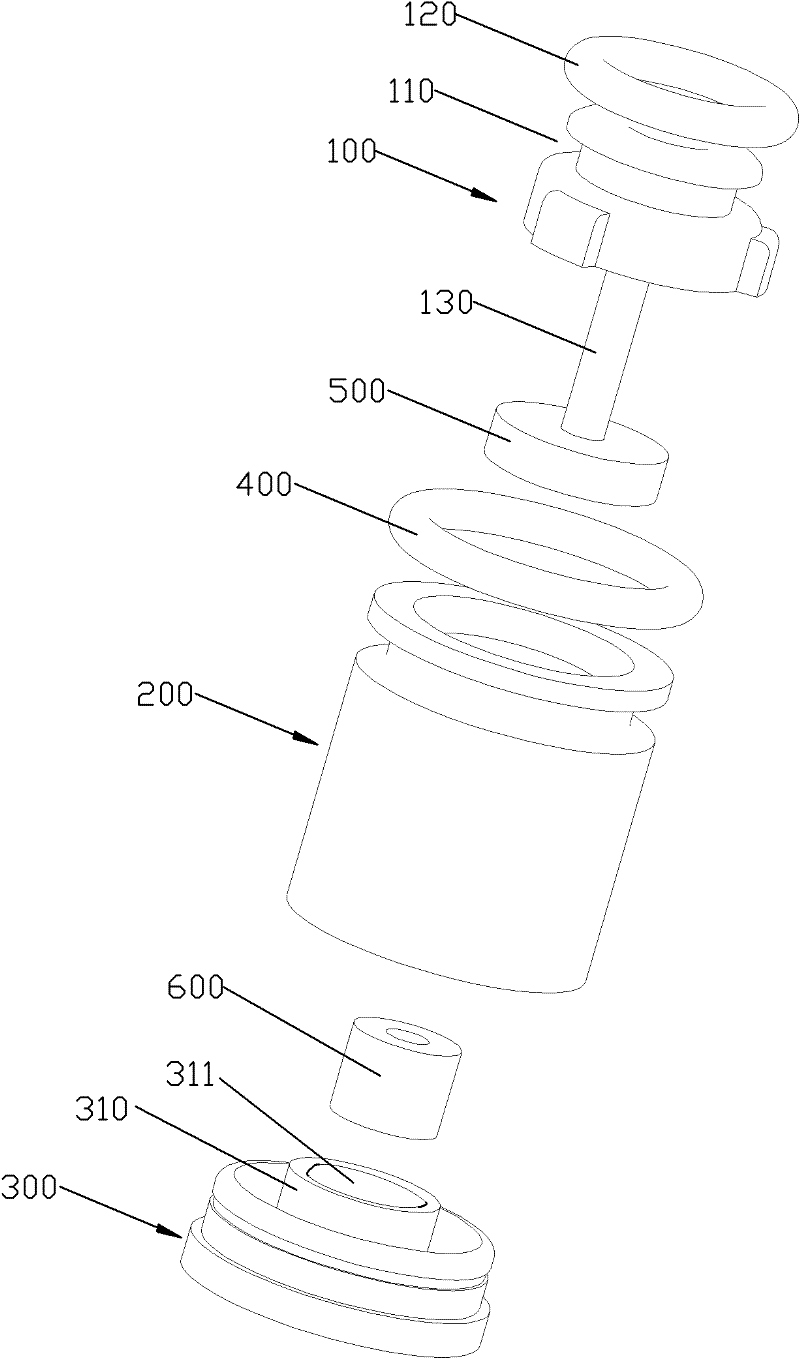

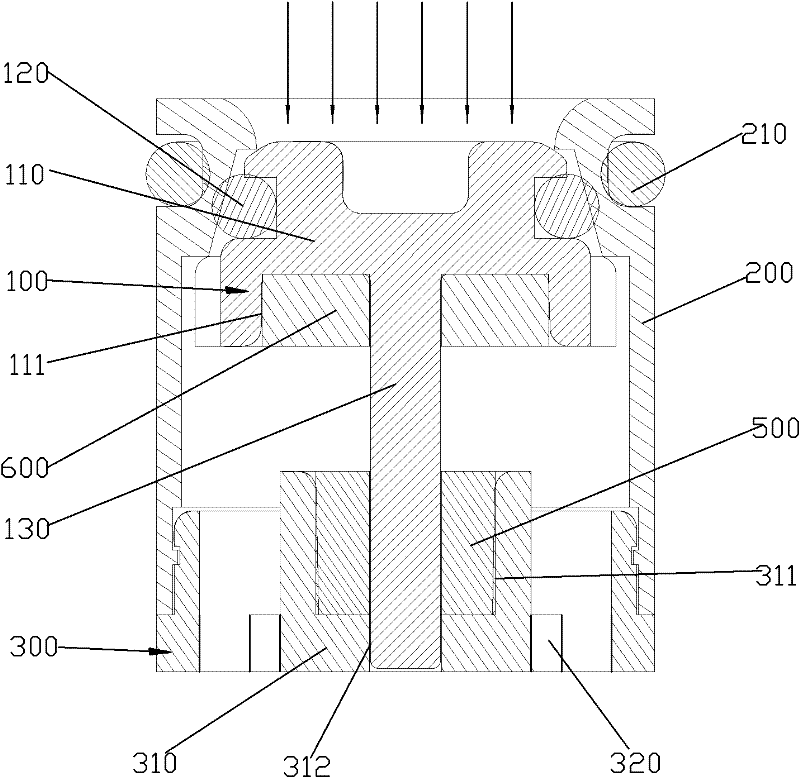

[0037] Please check Figure 1 to Figure 5 , a magnetic check valve, which includes a fixed unit and a spool 100.

[0038] The fixing unit includes a valve body 200 , a valve seat 300 and an outer sealing ring 400 . The outer sealing ring 400 is sleeved on the outer rotating surface of the valve body 200 . The tail of the valve body 200 is concavely provided with a card slot on the inner turning surface, and the outer turning surface of the valve seat 300 is provided with a card edge, and the card edge and the card slot are fitted together to lock the valve body. 200 and valve seat 300 are affixed together. In this embodiment, the valve body 200 and the valve seat 300 form a water inlet channel, the head of the valve body 200 becomes the water inlet end of the water inlet channel, and the valve seat 300 becomes the water inlet channel. Outlet. The inner rotary surface of the valve body 200 is provided with an annular flange 210 protruding inward. The annular flange 210 has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com