Magnetic tensile machine

A tensioner and magnetic technology, applied in the direction of wind power engine, machine/engine, wind power motor combination, etc., can solve problems such as no satisfactory technical solutions, no mature products, etc., achieve simple structure, improve power generation efficiency, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

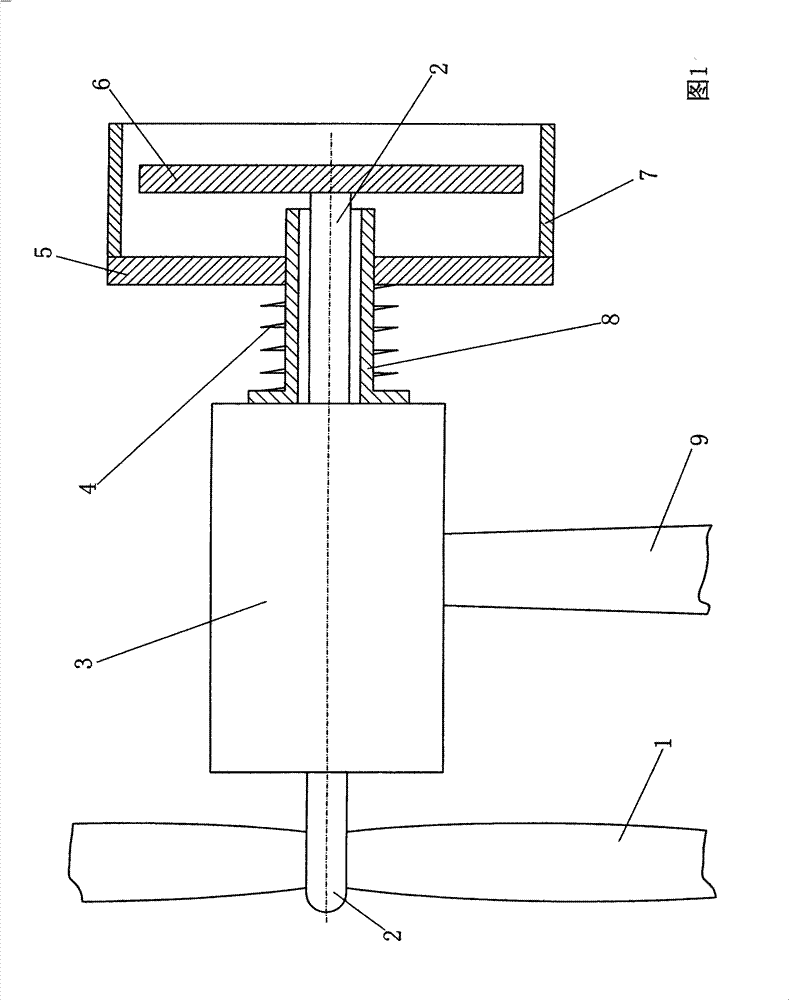

[0014] Embodiment 1: as shown in Figure 1. Described magnetic puller is constituted like this: from the non-magnetic sleeve 8 on the left side band edge of coaxial sleeve left side of the rotating shaft 2 tail (right) end of generator 3, the inner circle of non-magnetic sleeve 8 does not contact the outer circle of shaft 2, non-magnetic The left end surface of the sleeve 8 is connected with the right end surface of the stator of the generator 3 or other static structural parts, and the right end surface of the shaft 2 protrudes from the right end surface of the non-magnetic sleeve 8; , the middle hole of the magnetic circular plate 5 and the small outer circle of the non-magnetic sleeve 8 form a sliding fit, and the left end of the tension spring 4 is connected with the surface of the non-magnetic sleeve 8 or the right end of the stator of the generator 3 or other static structural parts 1. The right end of the tension spring 4 is connected with the left end face of the magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com