Thin coal bed fully-mechanized mining scraper conveyor

A scraper conveyor, thin coal seam technology, used in conveyors, earthwork drilling, slitting machinery and other directions to achieve the effect of improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

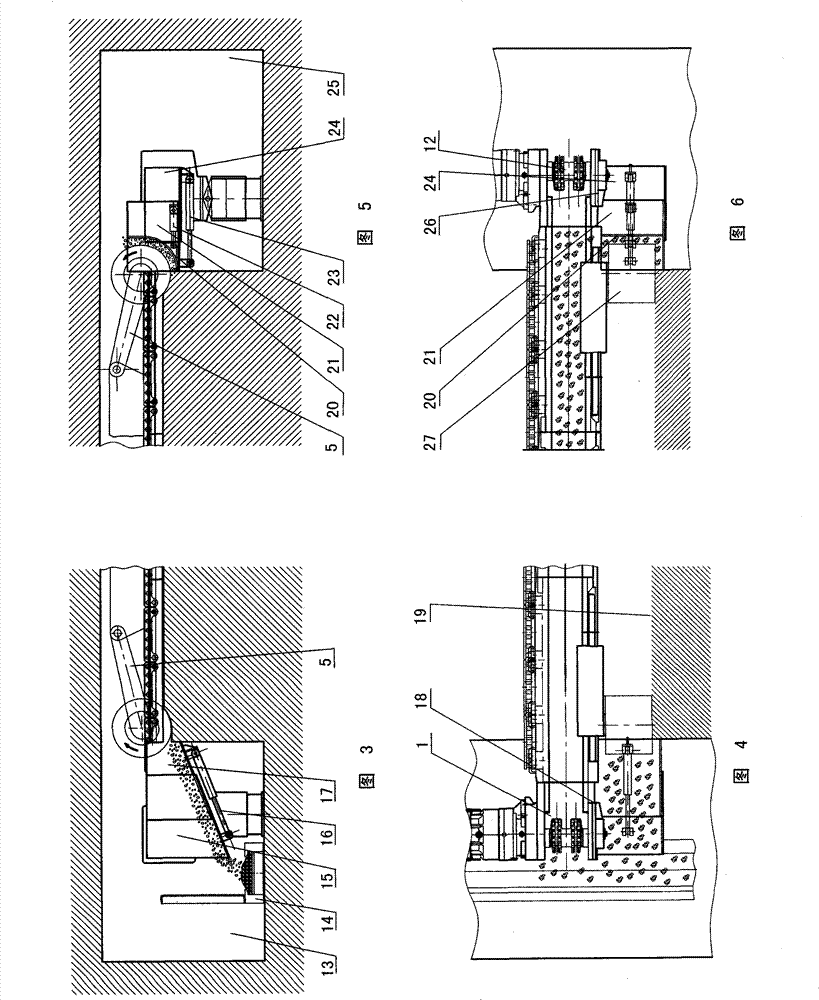

[0023] The present invention will be further described below in conjunction with drawings and embodiments.

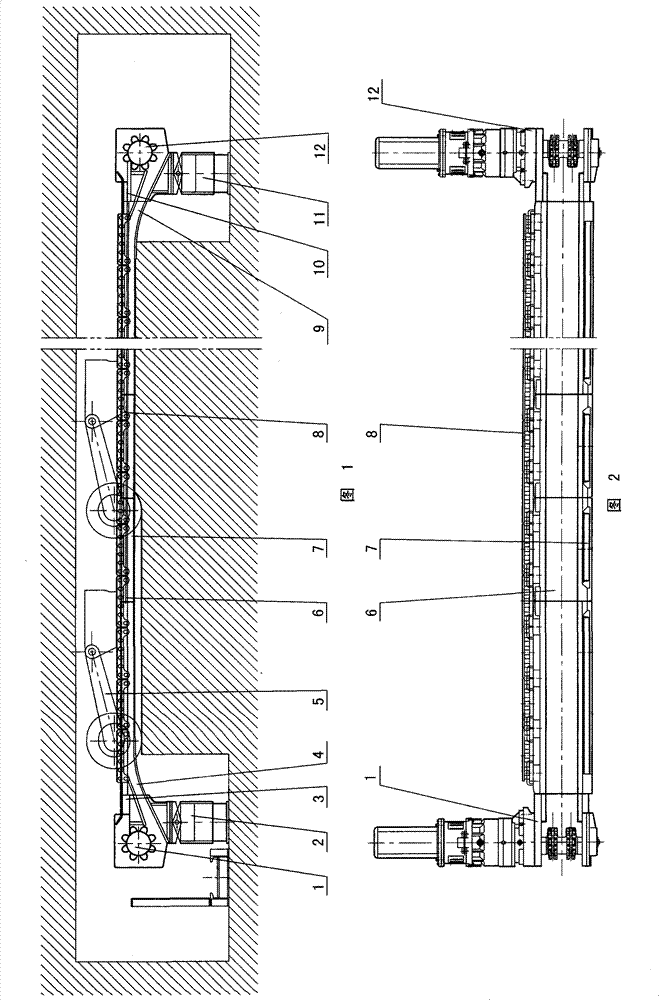

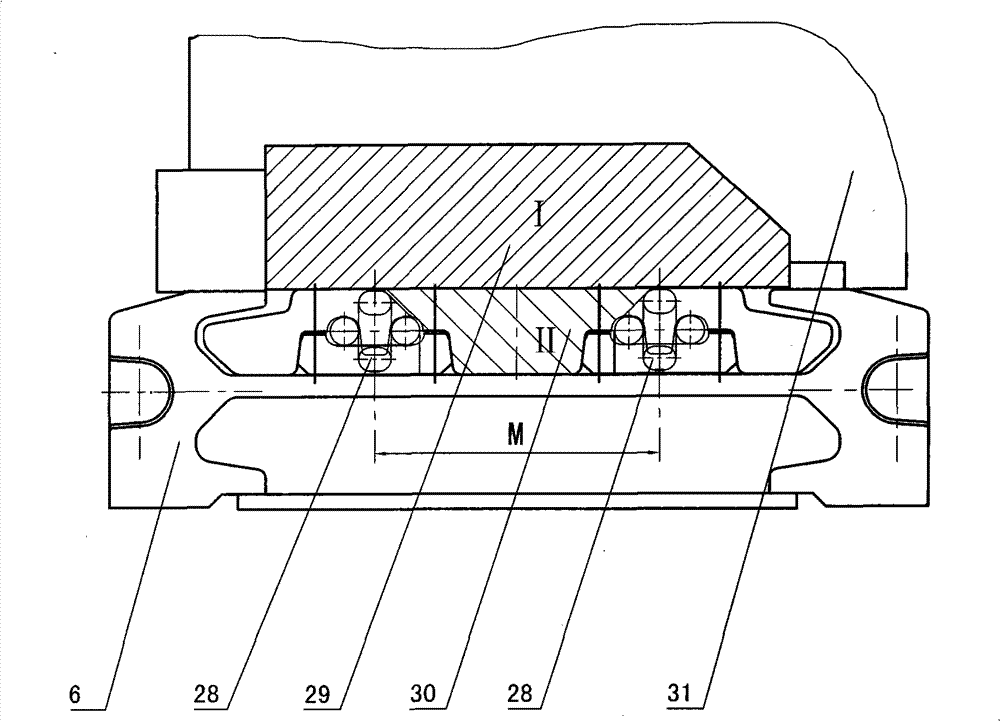

[0024] exist figure 1 , 2 The composition of the thin coal seam fully mechanized scraper conveyor of the present invention is shown in the figure. It is a scraper conveyor with straight arrangement of head and tail middle plate, mainly composed of head 1, tail 12, middle groove 6, scraper chain and so on.

[0025] 1. The middle plate of the head and tail of the scraper conveyor is arranged in a straight line:

[0026] ①In the entire laying length of the scraper conveyor, the middle plates of the head 1 and tail 12 and the middle plate of the middle groove 6 are arranged horizontally and at the same height, and they are always arranged in a consistent manner. The angle between the middle plate of the nose 1, the tail 12 and the middle plate of the middle groove 6 is preferably about zero degree, and there can be an upwarping angle of +6 degree to a descending angle o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com