Pulsating cleaning method

A cleaning cycle and front-washing technology, applied in the field of water treatment, can solve the problems of complex cleaning methods, difficult cleaning, and difficulty in obtaining ideal results from pulsed hydraulic backwashing, saving flushing time and flushing water volume, and improving cleaning effects. , to solve the effect of hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below in conjunction with the embodiments shown in the accompanying drawings.

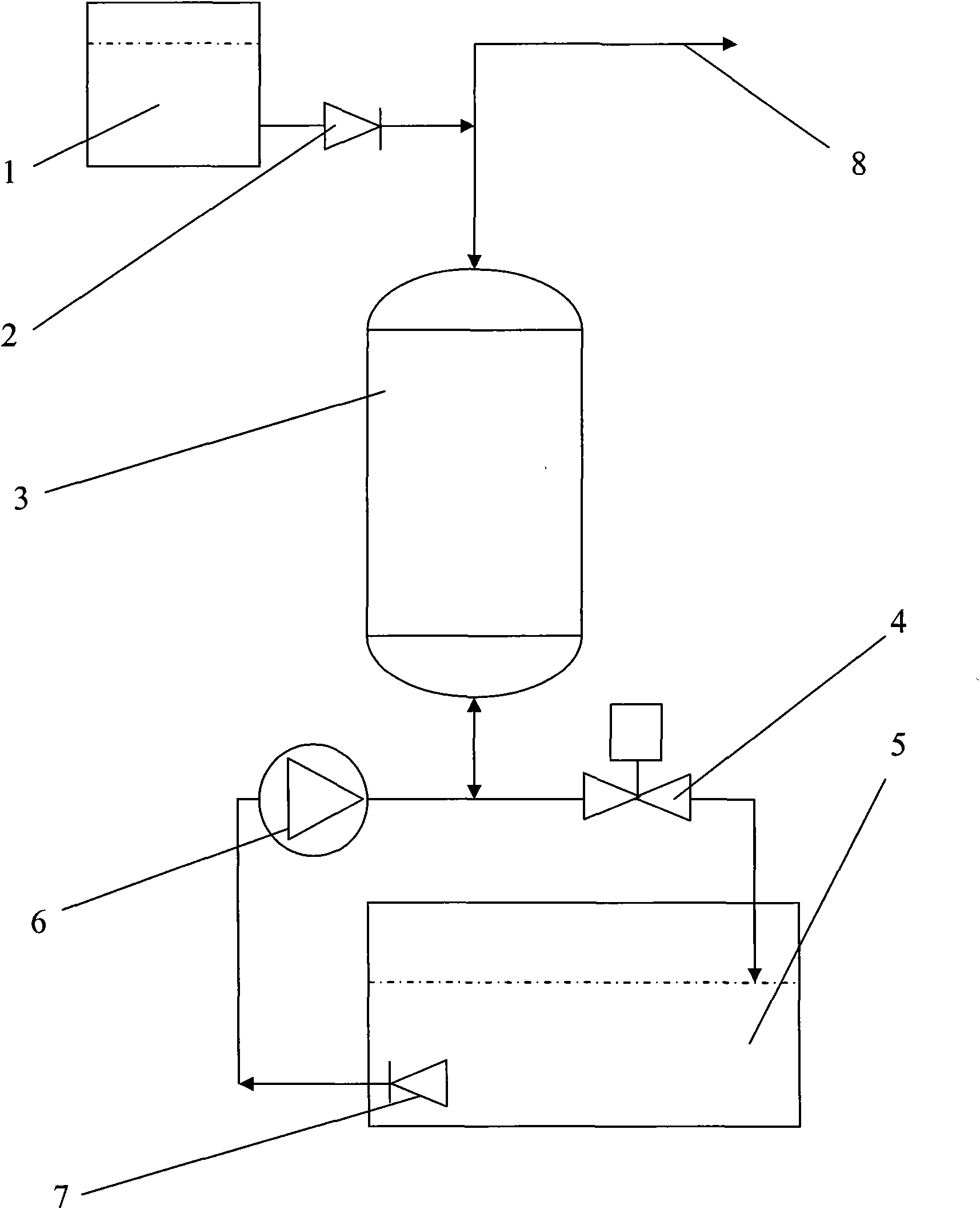

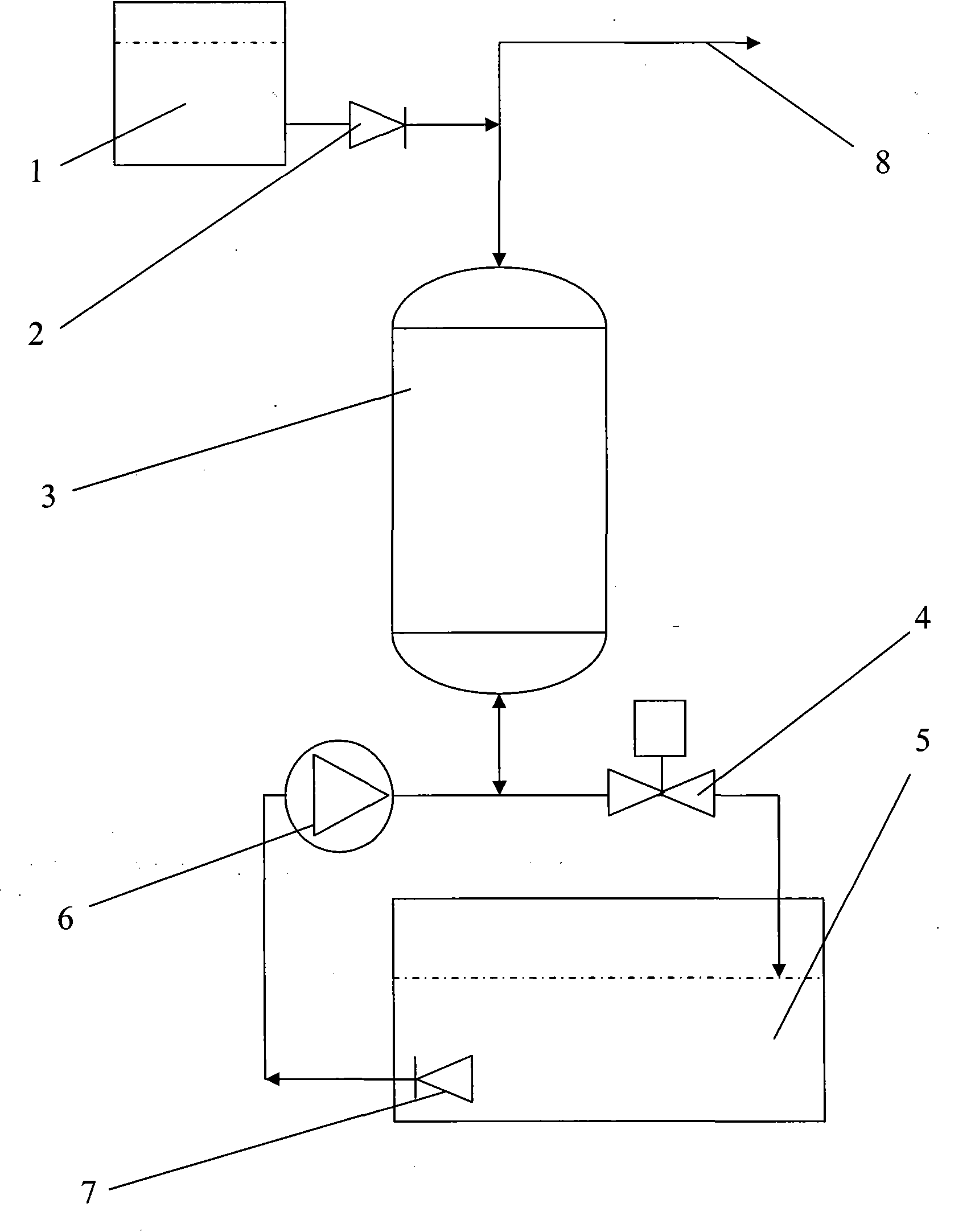

[0010] as attached figure 1 A pressure-type mechanical filtration system is formed, and the main equipment includes a high-level raw water tank (1), a check valve (2), a mechanical filter (3), a solenoid valve (4), a low-level clean water tank (5), and a backwash pump (6) and check valve (7) constitute. (8) is backwashing sewage pipe.

[0011] During forward filtration, the raw water enters the mechanical filter (3) from the high-level raw water tank (1) through the check valve (2) for filtration, and the filtered clean water flows into the low-level clean water tank ( 5). Due to the effect of the check valve (7), clear water will not pass through the backwash water pump (6).

[0012] When the filter system is cleaning the filter, the electric control system controls the solenoid valve (4) and the backwash water pump (7) to perfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com