Roller-type hay cutter

A lawnmower and roller-type technology, applied in the field of roller-type lawnmowers, can solve problems such as unfavorable transportation, incomplete cutting, unfavorable fuel full combustion, etc., and achieve the effect of improving power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

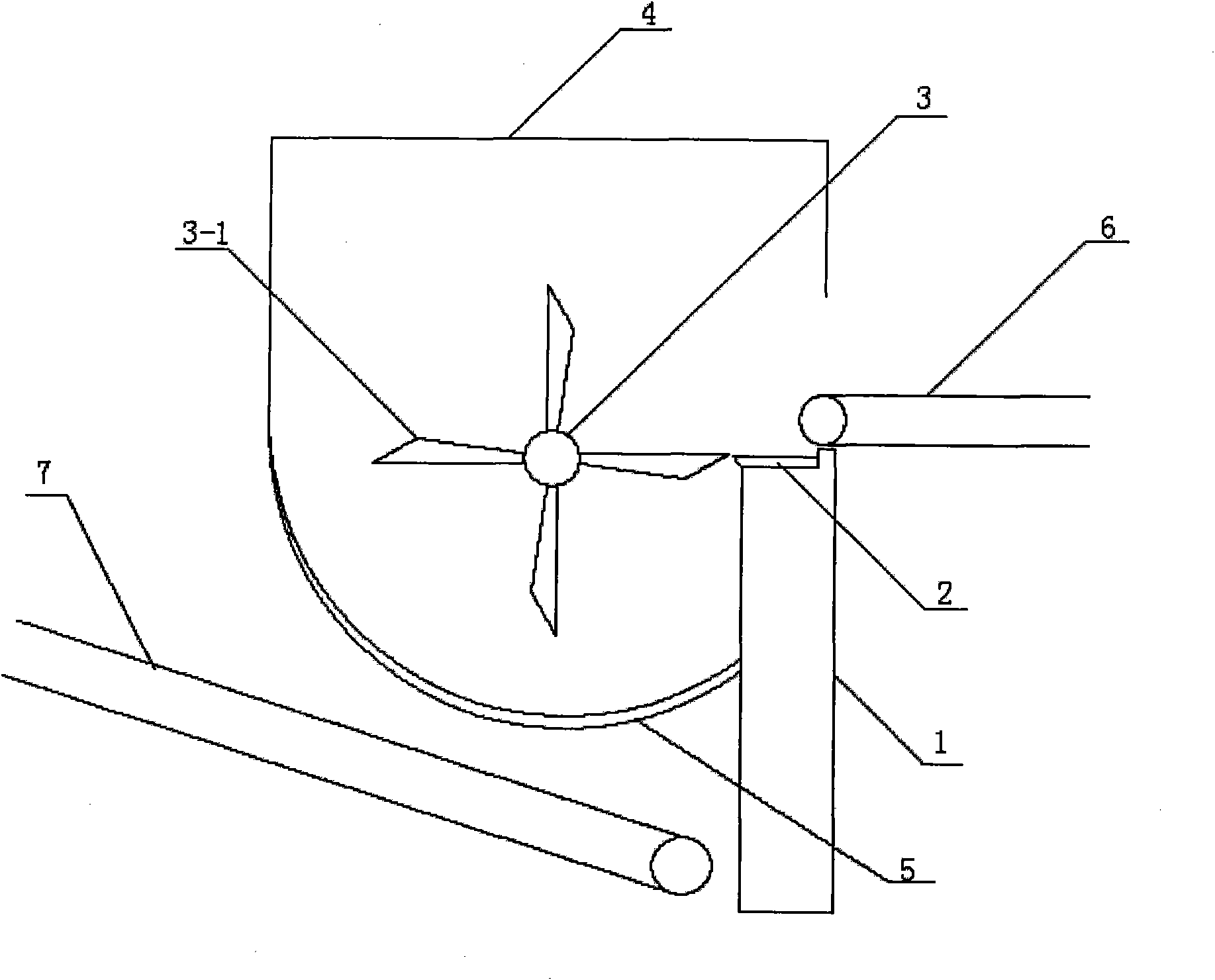

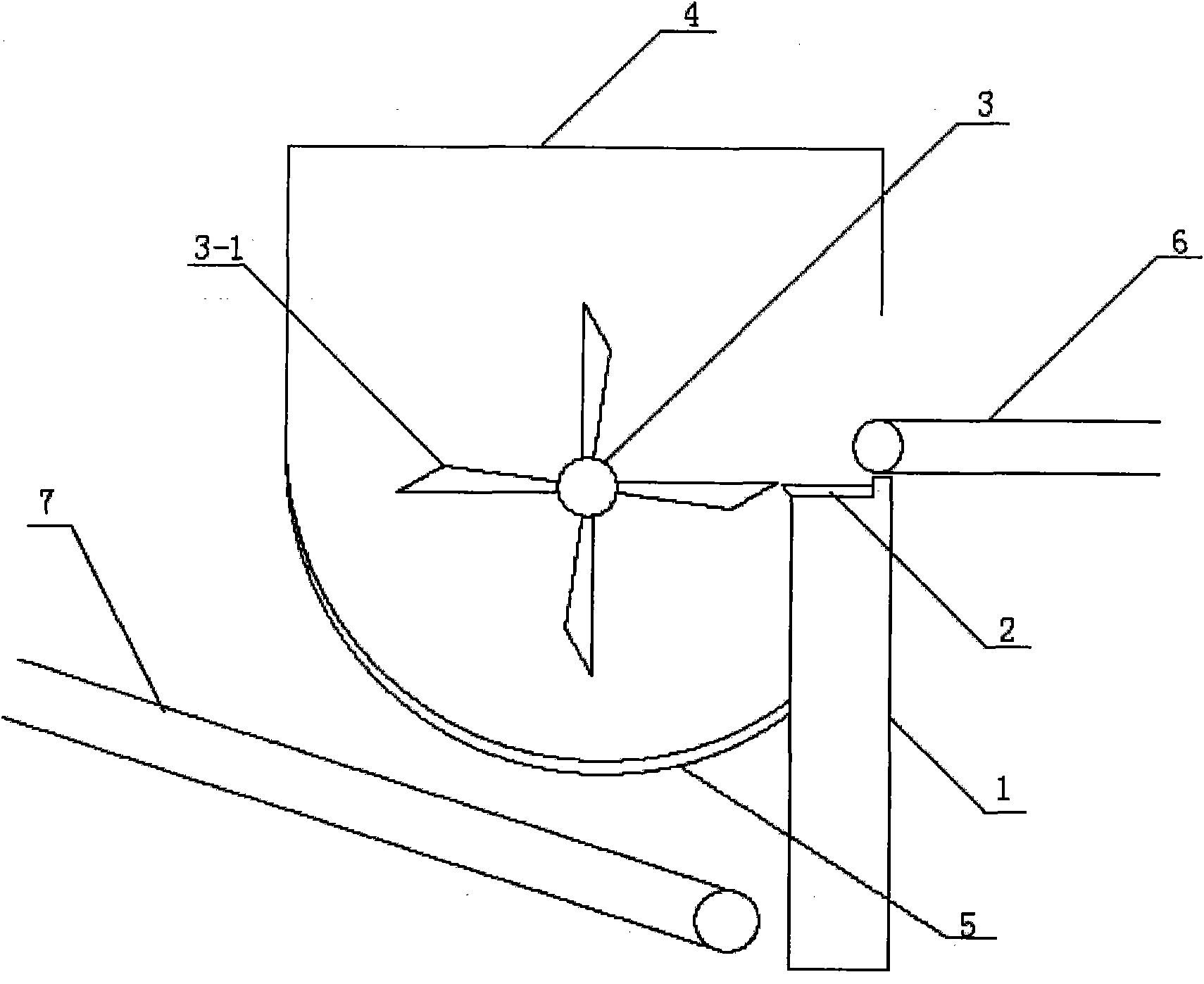

[0010] As shown in the figure: the bottom knife 2 is set on the upper part of the frame 1, the sealing cover 4 covers the knife roller 3 equipped with the flying knife 3-1, and a sieve plate is installed under the side of the knife roller 3 and directly above the discharge belt 7 5. The sieve plate 5 is connected with the sealing cover 4 and the base 5 . A feeding belt 6 is installed above the frame 1 . The knife roller 3 is connected with the motor through a transmission device (not shown in the figure)

[0011] Specific working process:

[0012] Fuel such as straw and fodder to be processed is transported to the inside of the sealing cover 4 through the feeding belt 6. At this time, the knife roller 3 equipped with the flying knife 3-1 rotates at a high speed. Due to the gap between the flying knife 3-1 and the bottom knife 2 The adjustment is between 0.1mm and 0.3mm, so the fuel such as straw and forage entering the inside of the sealing cover 4 is chopped by the flying k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com