Punch unit

A technology for discharging holes and punching dies, applied in metal processing, etc., can solve problems such as difficulty in core alignment, increased cost, and increased number of parts, and achieve the effects of improved perforation quality, compact structure, and increased rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

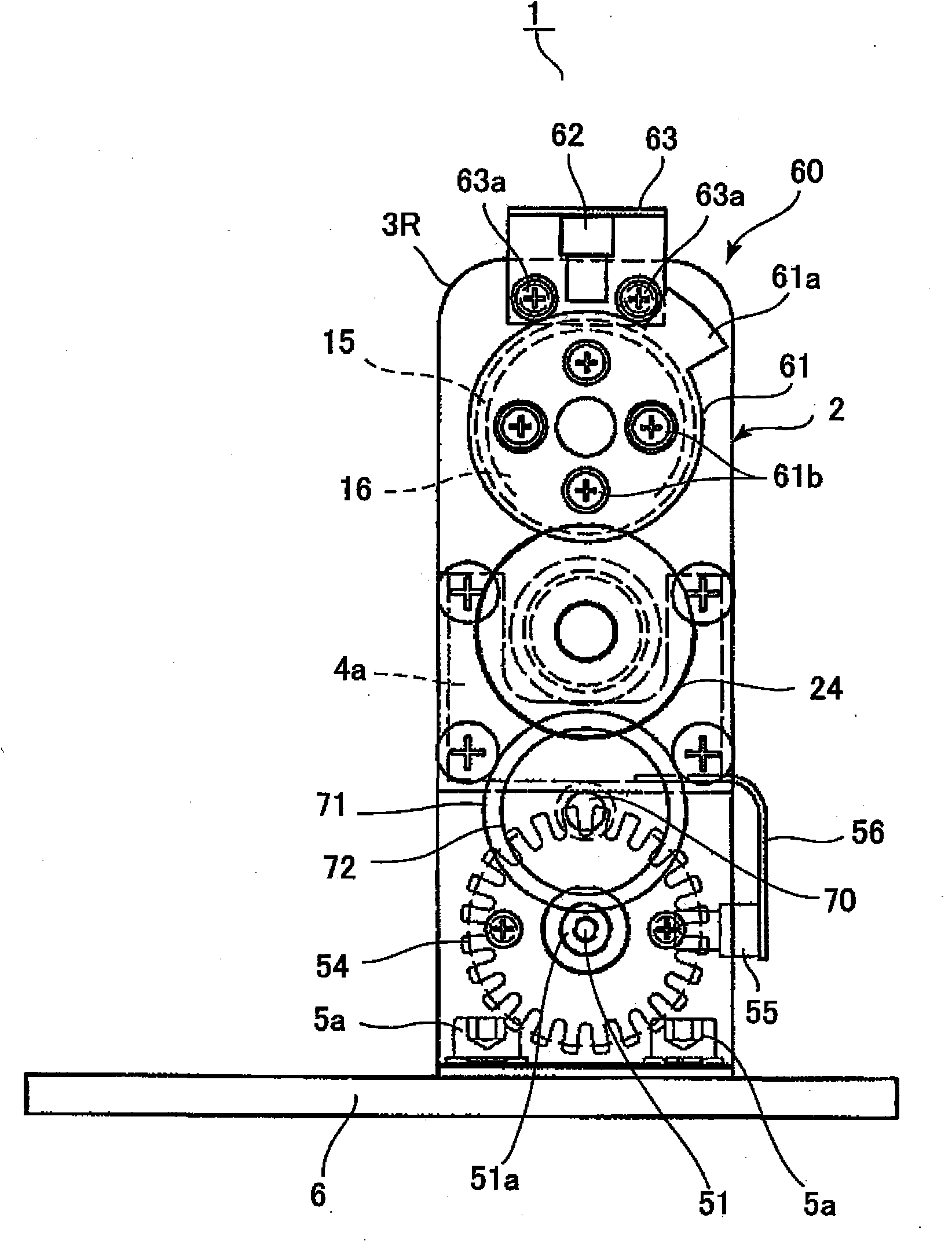

[0033] Perforation unit 1, such as figure 1 image 3 As shown, there is a base 6 fixed to the frame of an image forming apparatus (including a post-processing device) such as a printer, and a bottom plate 4 is fixed to the base 6 with bolts 5 a via a plurality of leg portions 5 . Left and right side plates 3L, 3R are fixed to left and right ends of the bottom plate 4, and the frame 2 is constituted by the above-mentioned integrated bottom plate 4 and side plates 3L, 3R. In addition, the punch shaft 10 and the die shaft 20 are arranged in parallel on the side plates 3L, 3R so that both ends thereof are rotatably supported, and the punch shaft 10 and the die shaft 20 together with the frame 2 form holes. Construction part (strength part) of unit 1. In addition, the punch shaft 10 and the die shaft 20 are supported by the side plates 3L, 3R with a predetermined gap W forming an engagement gap through which a sheet passes.

[0034] The above-mentioned punch shaft 10 is constit...

Embodiment approach 2

[0053] Figure 4 and Figure 7 (b) shows the punching unit according to Embodiment 2 of the present invention. In this embodiment, the chip discharge screw plate 30 fixed in the first embodiment has a structure in which a round bar is made into a helical blade, and is integrally arranged in the hollow portion 21a of the die shaft 20, and the configurations different from those in the first embodiment will be described below. part.

[0054] Such as Figure 4 and Figure 7 As shown in (b), the chip discharge screw rod 80 (guide, screw structure) as the hole chip conveying body is made of a round rod as a helical blade, and is fitted into the hollow part 21a of the die shaft main body 21 to be integrally installed. . Therefore, when the die shaft 20 rotates, the chip discharge screw 80 rotates integrally with the inner peripheral surface of the hollow portion 21a of the die shaft main body 21, and the hole chips flow along the edge of the chip discharge screw 80 based on the...

Embodiment approach 3

[0059] Figure 5 , Figure 6 as well as Figure 7 (c) is a diagram showing a punching unit according to Embodiment 3 of the present invention. In this embodiment, the fixed chip discharge spiral plate 30 in the first embodiment is changed to a coil-shaped member, and the coil member is driven by a motor. The parts different from the configuration of the first embodiment will be described below.

[0060] Such as Figure 5 , Figure 6 as well as Figure 7 As shown in (c), the chip discharge coil (guide, screw member) 90 as the hole chip conveying body is formed by winding a metal wire or a plastic flexible member into a cylindrical shape, and is installed on one end thereof. There is a drive gear 94 . The chip ejection coil 90 from the Figure 5 The direction of arrow A indicated by arrow A is arranged in the hollow portion 21a of the die shaft main body 21 toward the direction B, and the drive gear 94 is rotatably supported on the side of the left side plate 3L.

[0061...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com