Slag discharging device and pulverized coal burner using same

A pulverized coal burner and combustion chamber technology, which is applied in the direction of the burner, burner, and combustion method of burning powder fuel, can solve the problems of affecting the combustion efficiency of the pulverized coal burner, the slag removal effect is not obvious, and the operation is troublesome. Achieve the effect of high degree of automation, convenient operation and saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

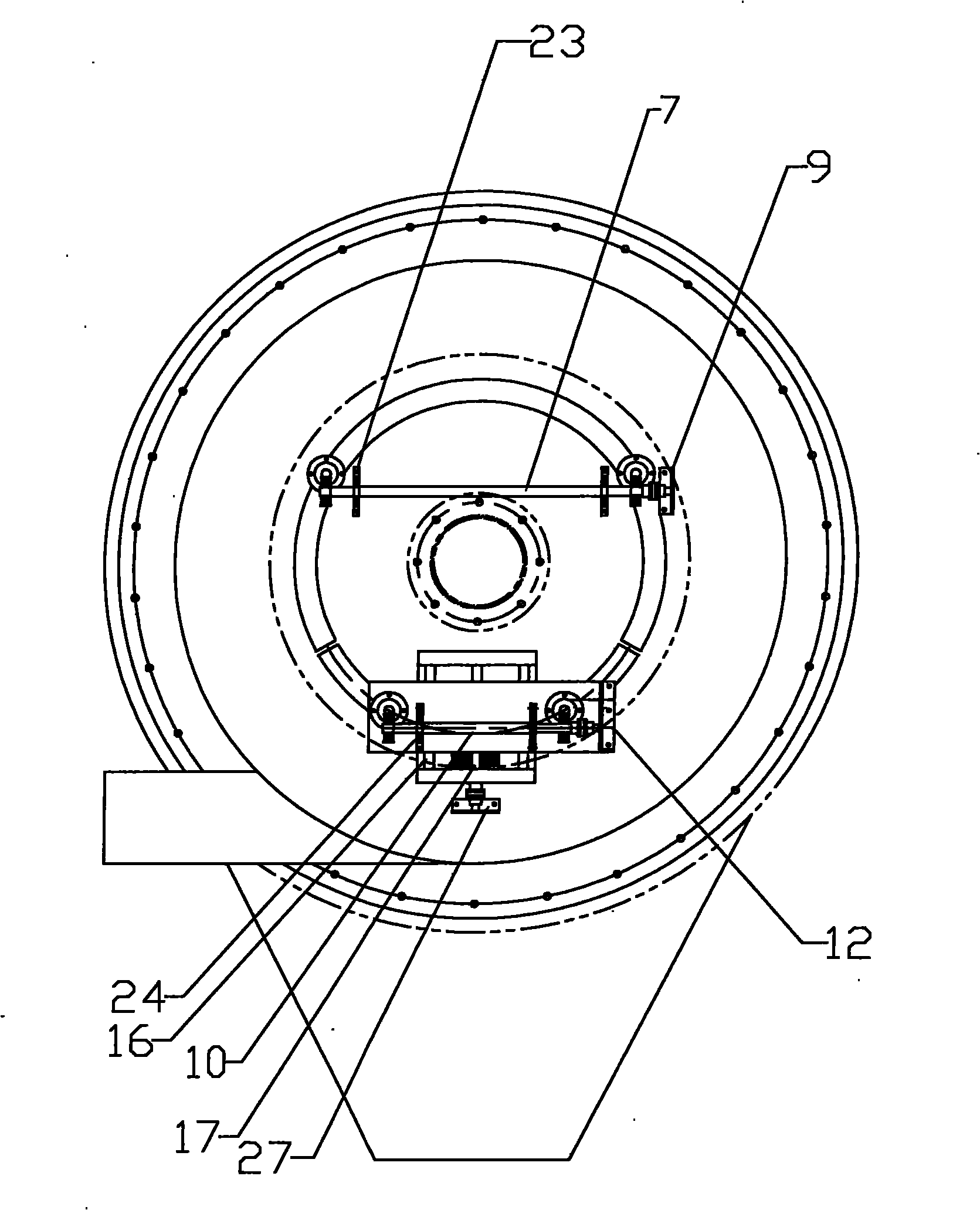

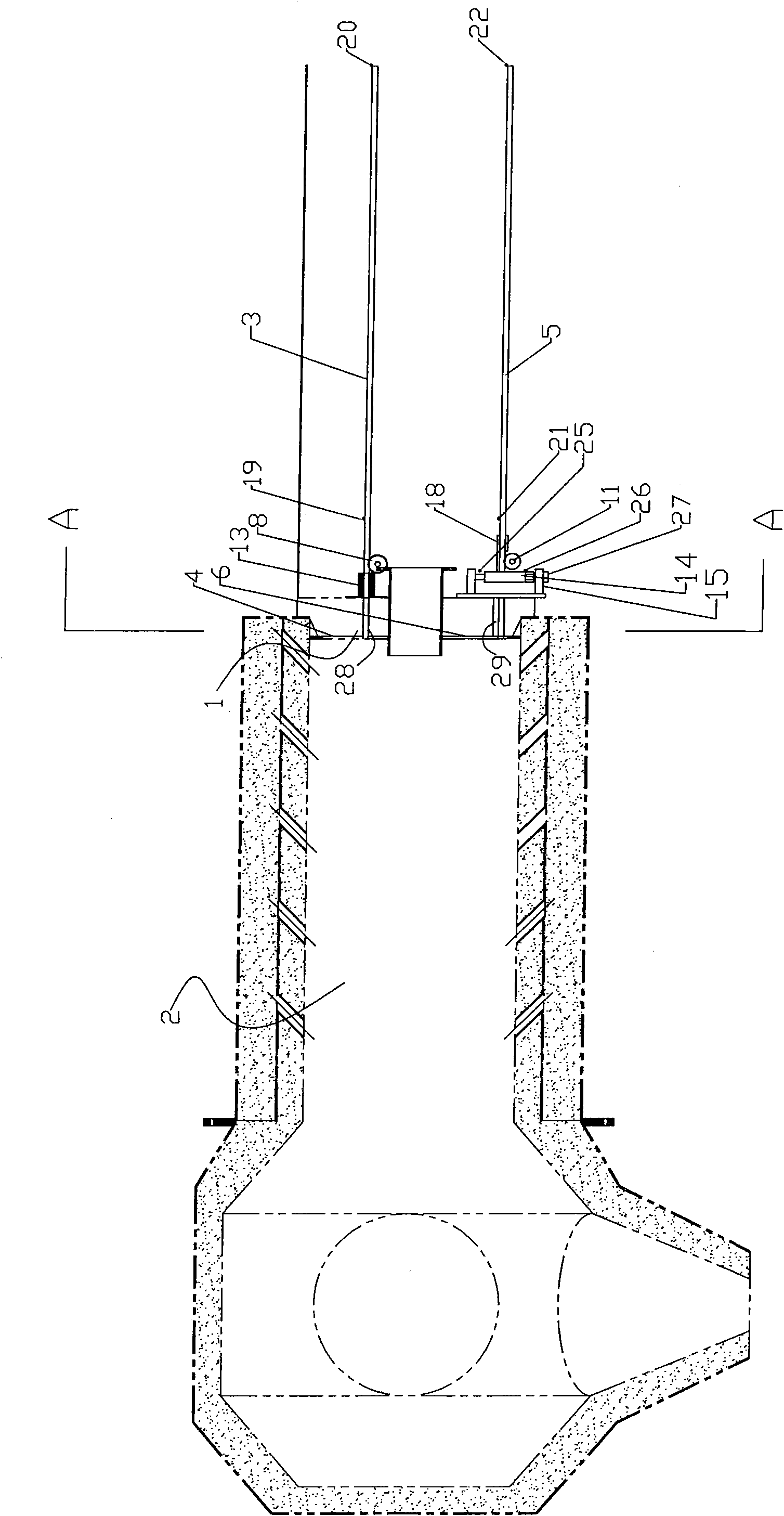

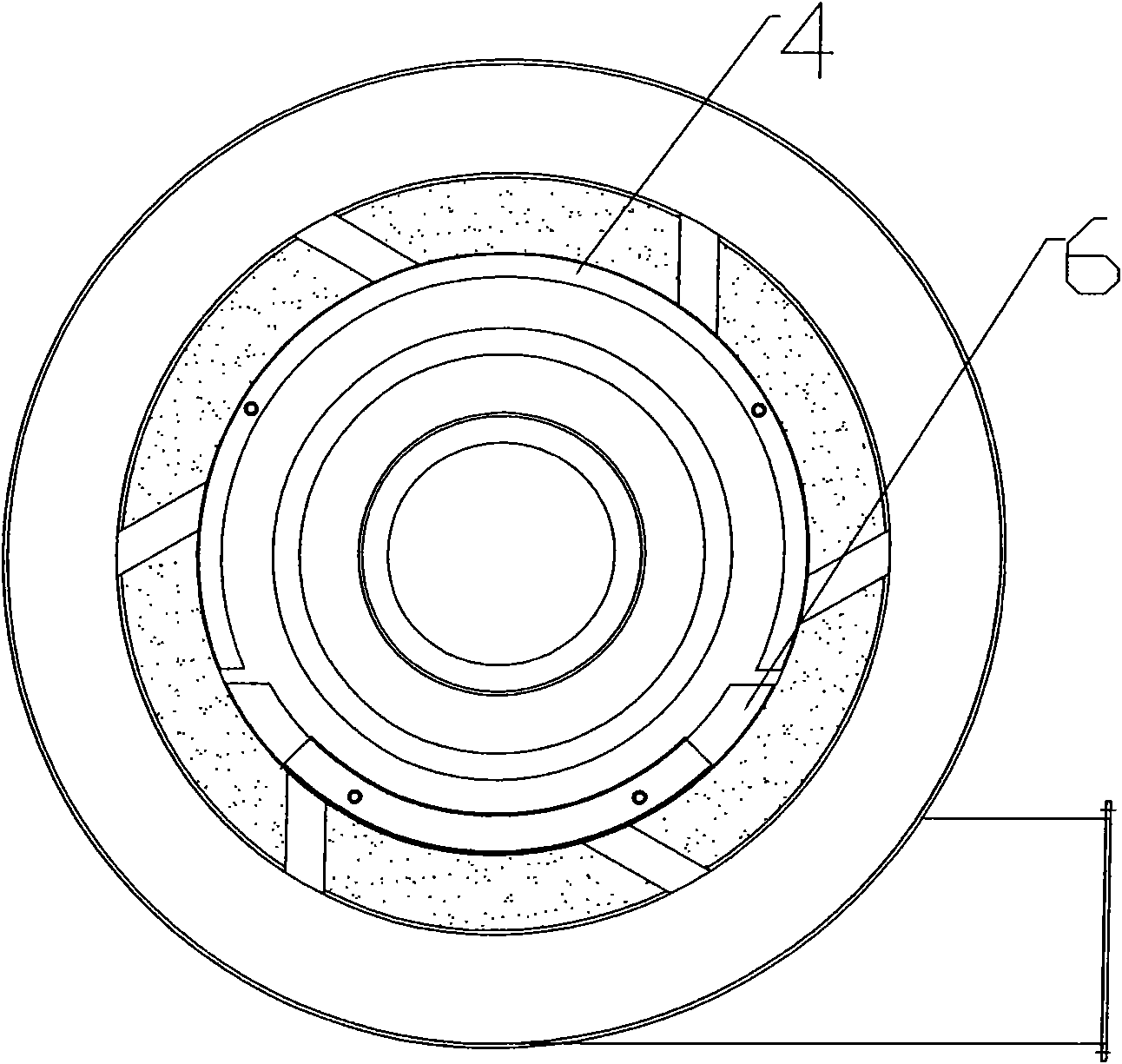

[0035] Such as Figure 1 to Figure 3 As shown, the slagging device of the present invention is used to be installed on a pulverized coal burner to realize real-time slagging, and includes an upper slagging structure and a lower slagging structure, and the upper slagging structure includes an upper push rod 3 and an upper slag pushing plate 4 And driving power unit I, the front end of the upper push rod 1 enters the interior of the combustion chamber 2 through the sliding hole I 28 arranged on the upper half of the combustion chamber door 1, and the outer edge of the upper slag pushing plate 4 is connected to the inner cavity wall of the combustion chamber The upper tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com