Flexible rope light

A flexible light strip and flexible technology, applied in lighting and heating equipment, semiconductor devices of light-emitting elements, point light sources, etc., can solve the problems of high production cost, short size, unsuitable high-voltage drive, etc., and reduce production and manufacturing costs , extend the length, and solve the effect of shorter lamp body size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

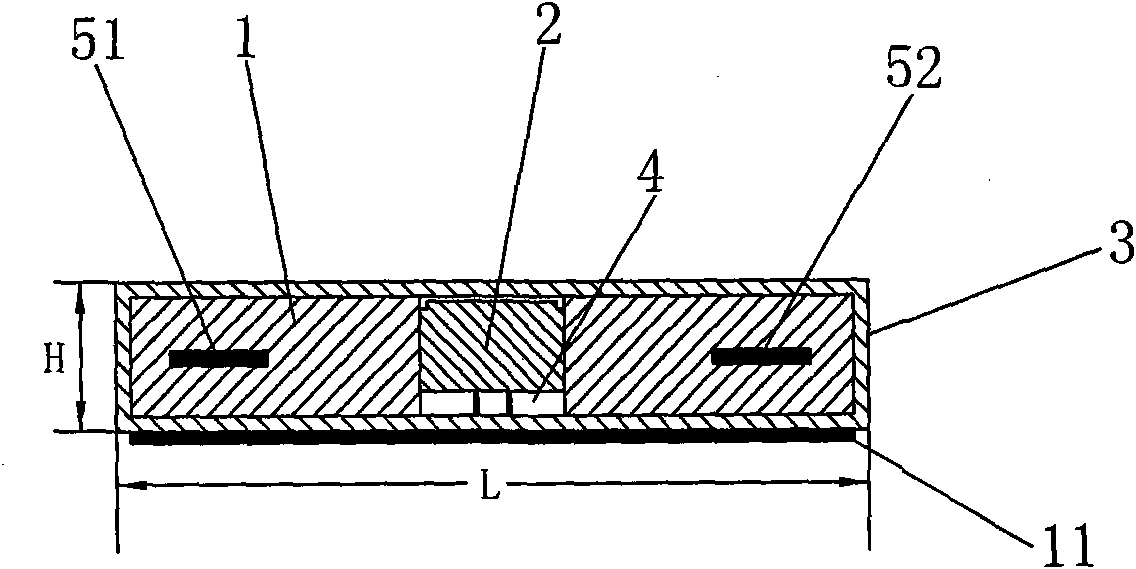

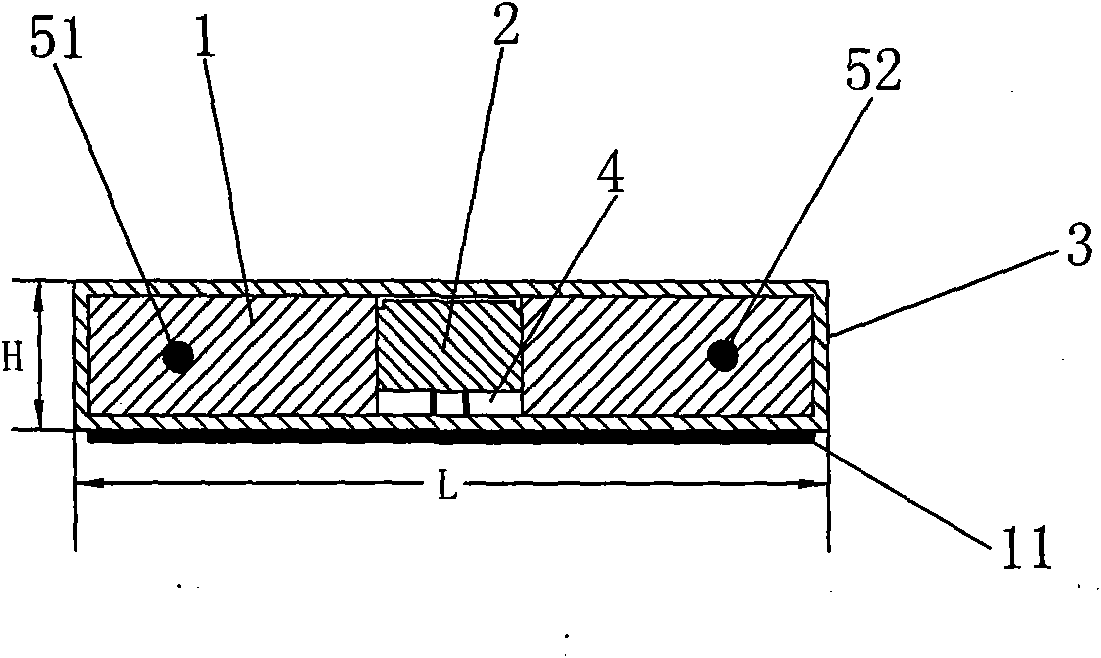

[0024] In order to further illustrate the structure of the present invention, a detailed description will be given below in conjunction with the accompanying drawings.

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the present invention discloses a flexible light strip, which includes a flexible core wire 1, a light string 20 installed in the core wire 1, and a flexible transparent coating layer 3 covering the core wire 1 and the light string 20. The light string 20 includes a plurality of SMD LED2s connected by conductive wires 7, and the light string 20 is also connected in series with a current-limiting resistor 6; the core wire 1 is provided with a plurality of transverse holes 4 for accommodating the SMD LED2, so The plurality of patch LEDs 2 are respectively installed in the transverse hole 4; the first and second main power lines 51 and 52 as the main power lines are arranged on both sides of the core wire 1, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com