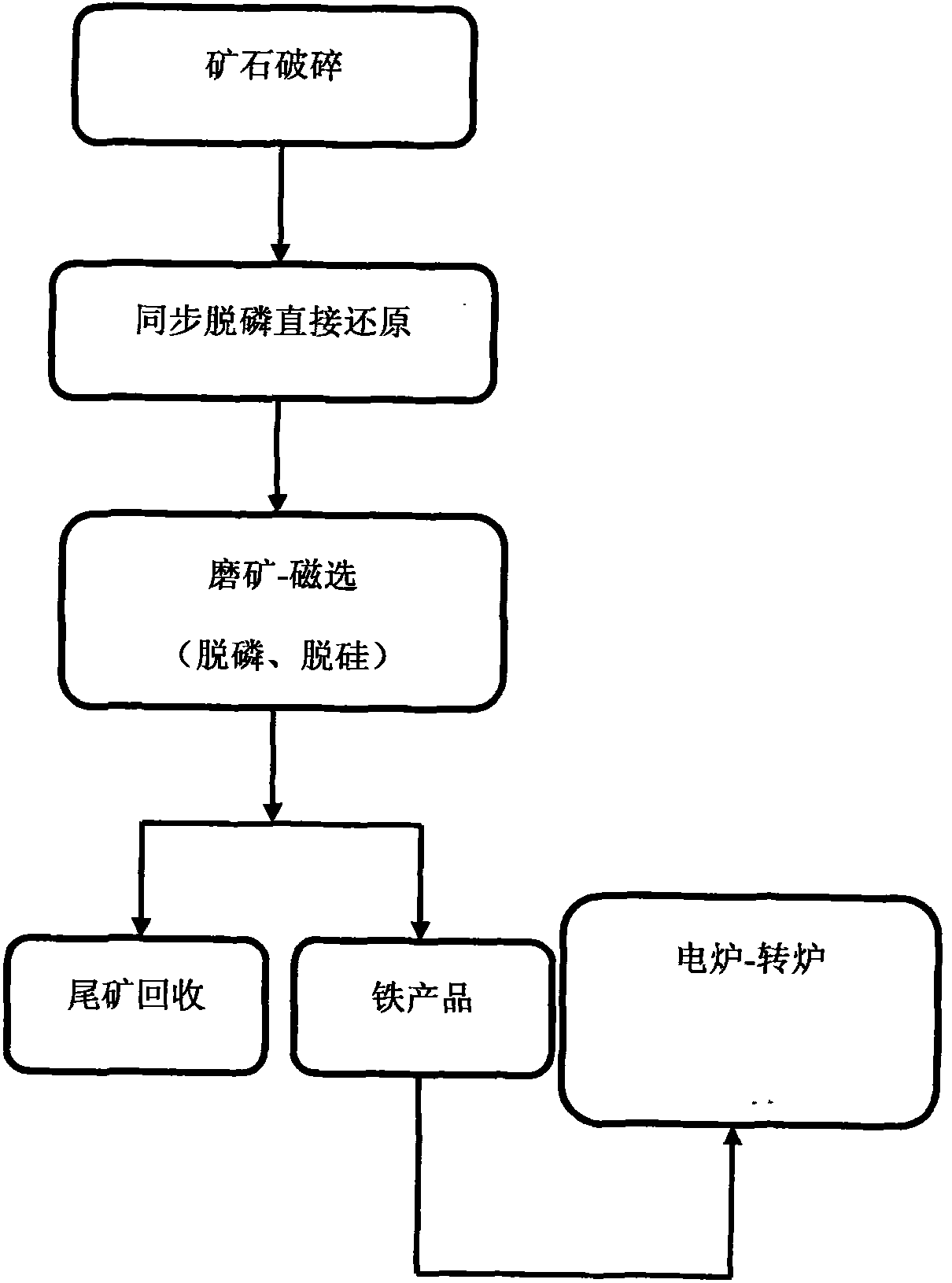

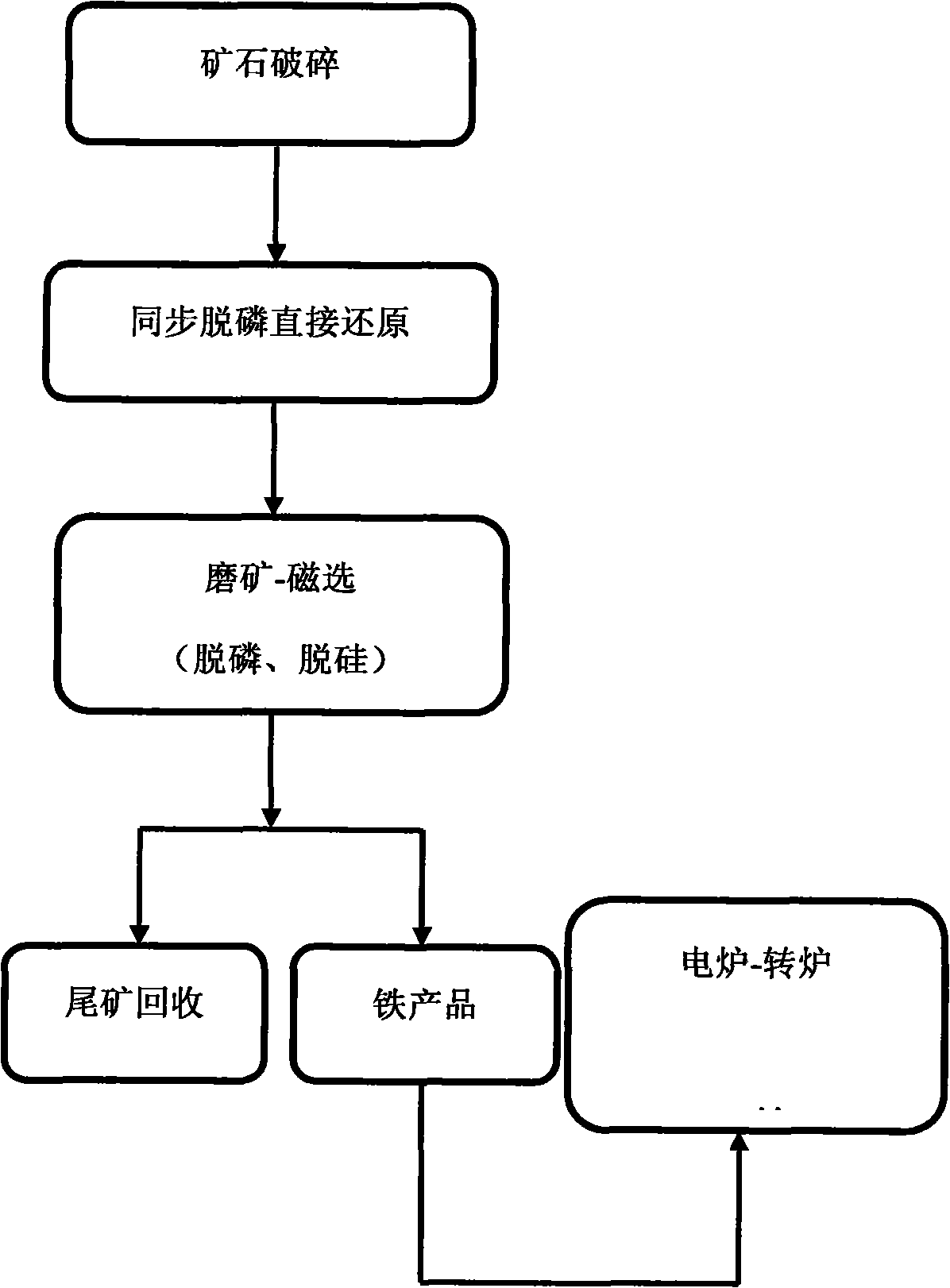

Method for preparing direct reduced iron from low-grade high-phosphorus high-silicon iron ore

A technology for reducing iron and lean iron ore, which is applied in furnaces, furnace types, fluidized bed furnaces, etc., can solve the problems of complex embedded particle size, unreported and applied, high phosphorus content, etc., achieving remarkable technical and economic effects, The effect of solving the contradiction between supply and demand of iron ore resources and high iron recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The composition of the raw iron ore used is: TFe: 47.24%, P: 0.907%, SiO 2 : 16.78%.

[0020] Go through the following steps:

[0021] 1. After the above raw ore is crushed by conventional crushing equipment until the particle size is less than 15mm, dephosphorize the crushed ore with coal powder reducing agent and sodium carbonate according to the mass ratio of ore: reducing agent: dephosphorizing agent = 100:30:25 When the RQ-35-2 rotary kiln is heated to 1000°C, add it into the rotary kiln, and roast it for 18 hours at this temperature and the rotary kiln speed is 3r / min to obtain loose primary direct reduced iron. ;

[0022] 2. Make the loose primary direct reduced iron in step 1 into pulp with a mass concentration of 67%, send it to a conventional grinding machine for grinding for 3 minutes, and the grinding fineness is: -0.074mm (200 mesh) accounting for 70%; Coarse magnetic separation is carried out under the condition of a magnetic field strength of 110kA / m (...

Embodiment 2

[0025] The original ore composition of the oxide ore used is: TFe: 45.62%, P: 0.91%, SiO 2 : 16.78%.

[0026] Go through the following steps:

[0027] 1. After the above raw ore is crushed by conventional crushing equipment until the particle size is less than 15mm, dephosphorize the crushed ore with lignite powder reducing agent and sodium sulfate according to the mass ratio of ore: reducing agent: dephosphorizing agent = 100:45:50 Mix the agent evenly, pack it in tanks, put it into a tunnel kiln with a size of 2.6×3.0×120 meters, and roast it for 50 hours at a temperature of 1150°C, and the high-temperature reduction time is 24 hours to obtain roasted ore, roasted ore The composition is: TFe: 40.23%, P: 0.76%, SiO 2 : 18.52%, MFe: 36.56%;

[0028] 2. Prepare the roasted ore from step 1 into a slurry with a mass concentration of 50%, grind it in a conventional ball mill for 20 minutes, and magnetically separate it in a conventional magnetic separator with a magnetic field ...

Embodiment 3

[0031] The raw ore composition of the oxide ore used is: TFe: 47.24%, P: 0.907%, SiO 2 : 16.78%.

[0032] Go through the following steps:

[0033] 1. After the above raw ore is crushed by conventional crushing equipment until the particle size is less than 15mm, dephosphorize the crushed ore with coke powder reducing agent and calcium bicarbonate according to the mass ratio of ore: reducing agent: dephosphorizing agent = 100:38:30 The phosphorus agent is mixed evenly, packed in tanks, put into a tunnel kiln with a size of 2.2×2.6×100 meters, and roasted for 50 hours at a temperature of 1200°C, and the high-temperature reduction time is 20 hours to obtain roasted ore. The composition is: TFe: 31.75%, P: 0.74%, SiO 2 : 19.82%, MFe: 25.78%;

[0034] 2. Make the roasted ore in step 1 into pulp with a mass concentration of 50%, grind it with a conventional baseball mill for 10 minutes, and magnetically separate it with a conventional drum magnetic separator with a magnetic field...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap