Material special for wood-like amino film plastics

A technology of amino molding compound and special material, which is applied in the preparation of imitation wood products or dark-colored products. The effect of production cost, saving forest resources and convenient modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

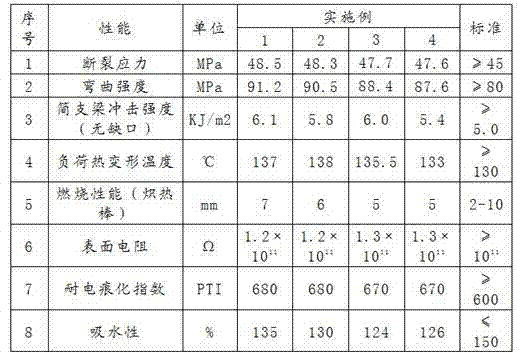

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be described in detail below in conjunction with specific embodiments.

[0024] Specific examples of the present invention are as follows: each composition component content (weight part) is as table 1:

[0025] Table 1 Formula of special material for imitation wood amino molding compound

[0026]

[0027] The amino resin is a polycondensate of formaldehyde and urea at a ratio of 1.1 to 1.2:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com