Steel-liner plastic container and processing process thereof

A technology for plastic containers and processing technology, applied in containers, large containers, linings/interior coatings, etc., can solve the problems of lining failure, deformation of anti-corrosion plastic linings, brittleness, etc., to reduce construction difficulty, improve work efficiency, high The effect of bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

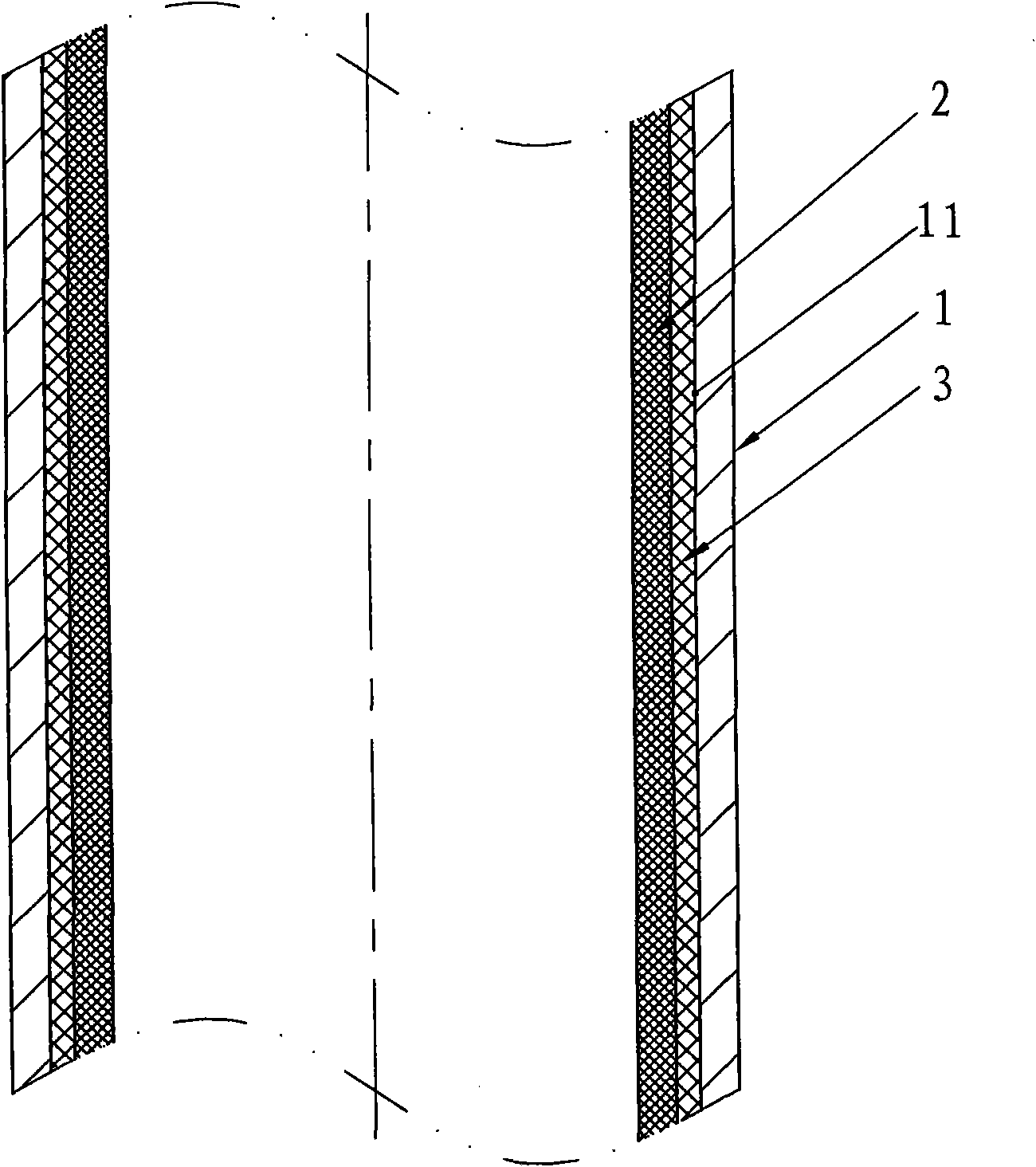

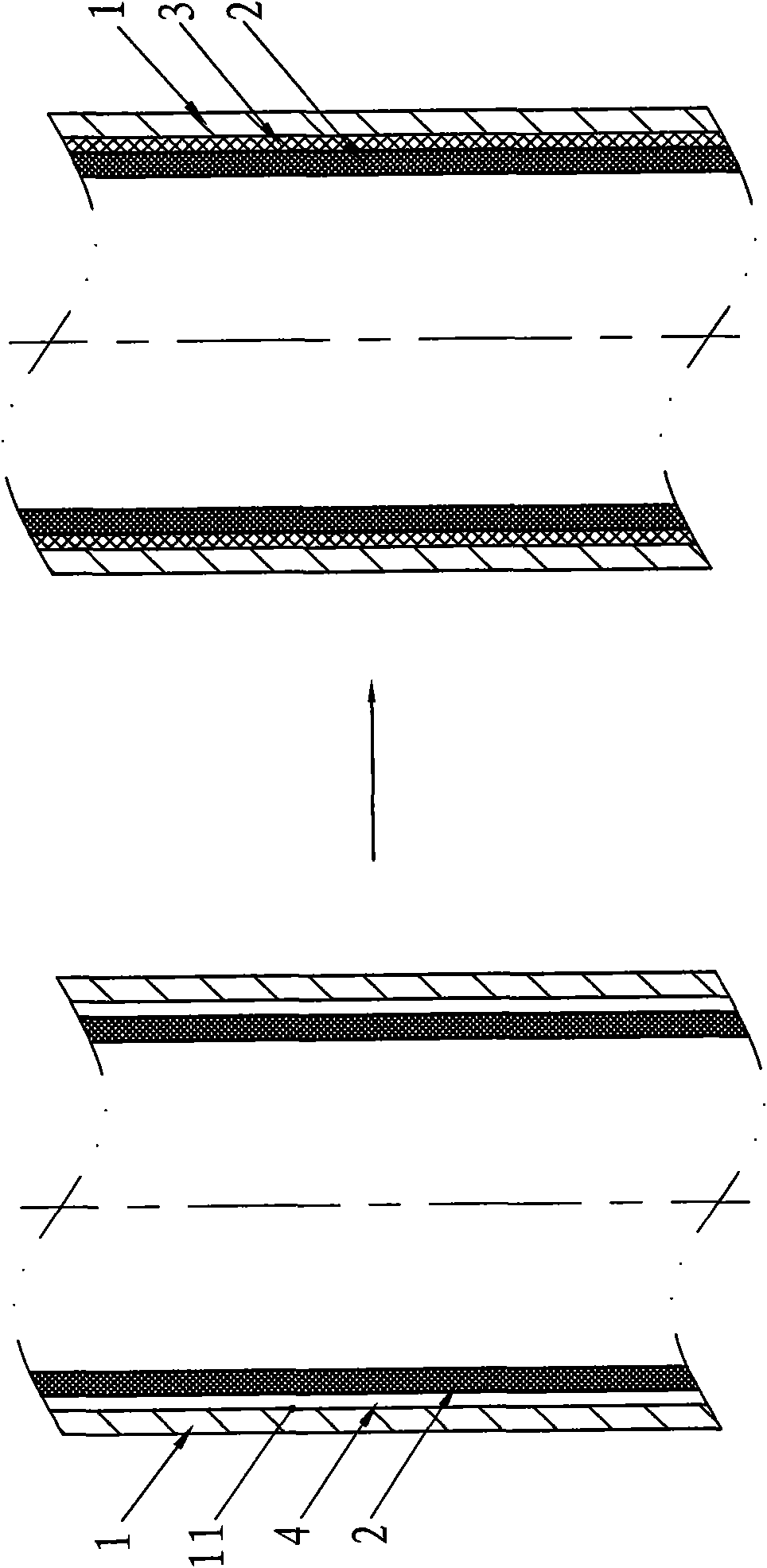

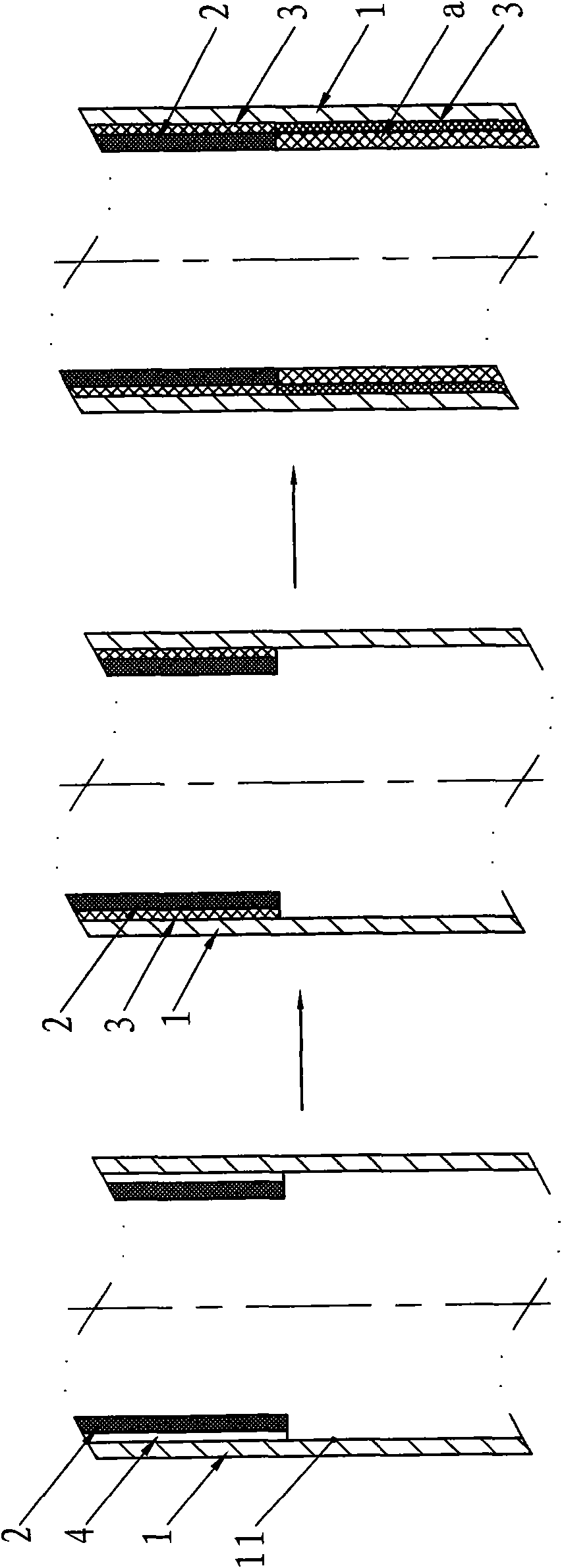

[0020] Such as figure 1 A steel-lined plastic container shown includes a container body 1 and an anti-corrosion plastic liner 2 attached to the container body 1. There is a filling space 4 between the inner wall 11 of the container body 1 and the anti-corrosion plastic liner 2. The filling space 4 is provided with an adhesive that forms the bonding of the anti-corrosion plastic lining 2 and the container body 1. In the embodiment of the present invention, the adhesive is resin 3, and the anti-corrosion plastic lining 2 can be polytetrafluoroethylene, polyethylene, polypropylene or other anti-corrosion plastics. By adding an adhesive between the anti-corrosion plastic lining 2 and the container body 1, a relatively perfect fixed bond is obtained between the anti-corrosion plastic liner 2 and the container body 1, and the resin 3 is used as the adhesive, which can not only play the role of adhesive It can also play the role of filling to prevent the anti-corrosion plastic linin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com