Sample preparing and demoulding integrated instrument

A demoulding and mold technology, applied in the field of sample preparation and demoulding combined instrument, can solve the problems of uneven density, water content, compaction noise pollution, low efficiency, etc., to save time and manpower, solve the problem of demoulding, avoid The effect of post-disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

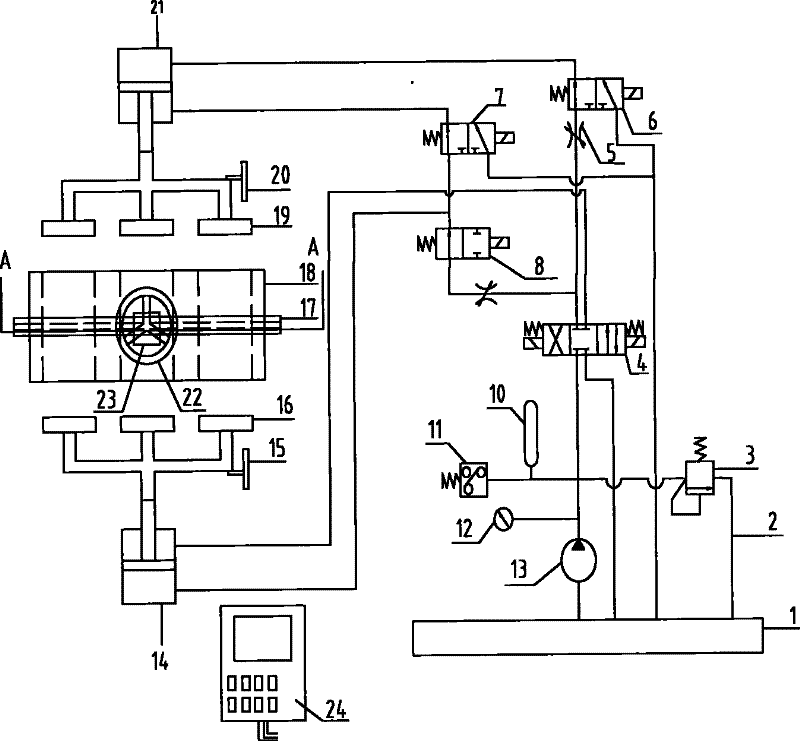

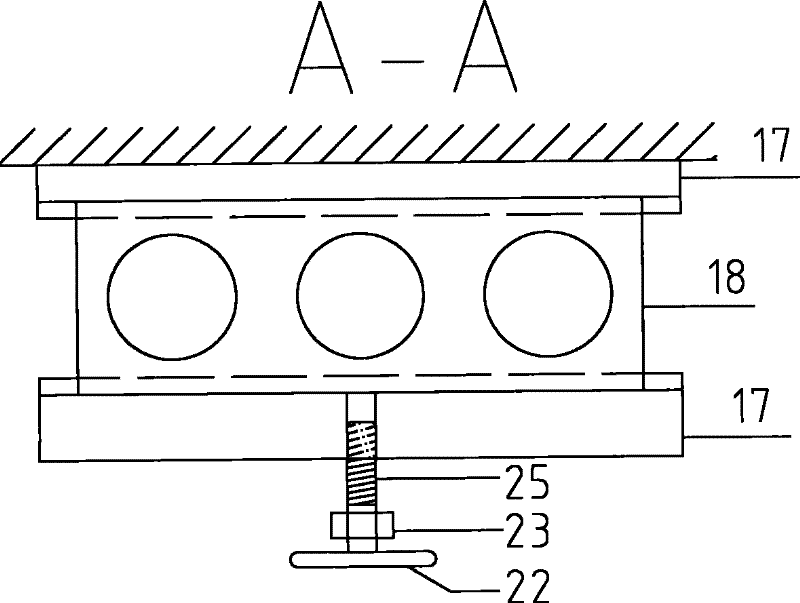

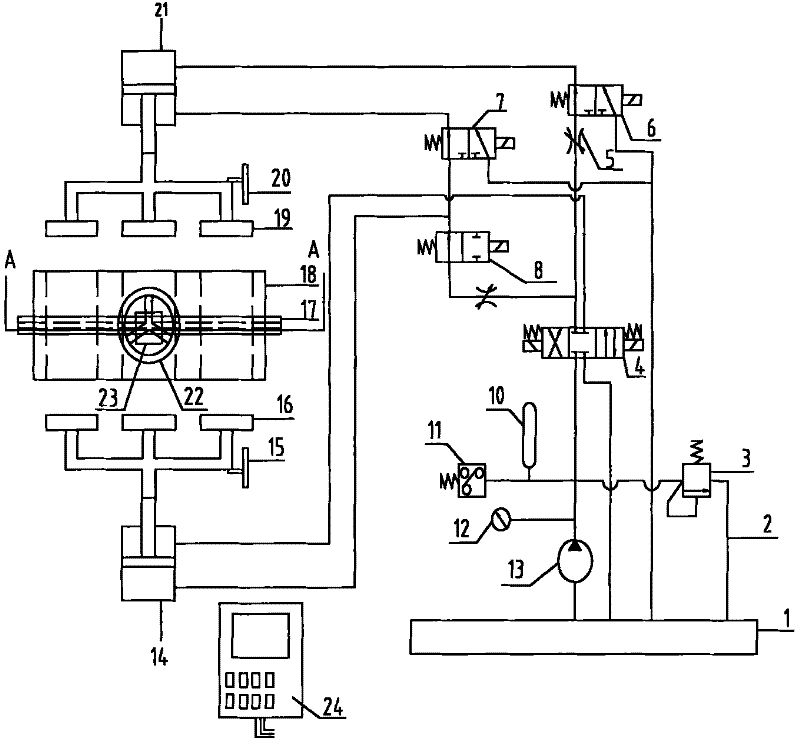

[0025] Such as figure 1 As shown, the combined instrument for sample preparation and demoulding at least includes a driving mechanism, a transmission mechanism driven by the driving mechanism, a base, and a filling mold 18 installed on the base. The specification and shape of the filling mold 18 can be changed at any time according to different requirements. , prepare different specifications and different shapes of test pieces, such as cylinders, round cakes, square columns, square cakes, hexagonal prisms, octagonal prisms, etc., the filling mold 18 can be two or more, and two or more filling molds The material molds 18 are parallel and juxtaposed together, and are tightened and installed on the base by a clamp. The clamp includes a clamp body 17, a screw mandrel 25, a support member 23 and a hand wheel 22. One end of the screw mandrel 25 is connected with the clamp body 17, and the hand wheel 22 Installed on the other end of the screw mandrel 25, the middle part of the screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com