Welding lower electrode device

A technology of electrode device and electrode clamp, which is applied in the direction of welding medium, welding equipment, welding equipment, etc., can solve the problems of inaccurate stroke judgment, stroke position error, spring characteristic change, etc. Eclipse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

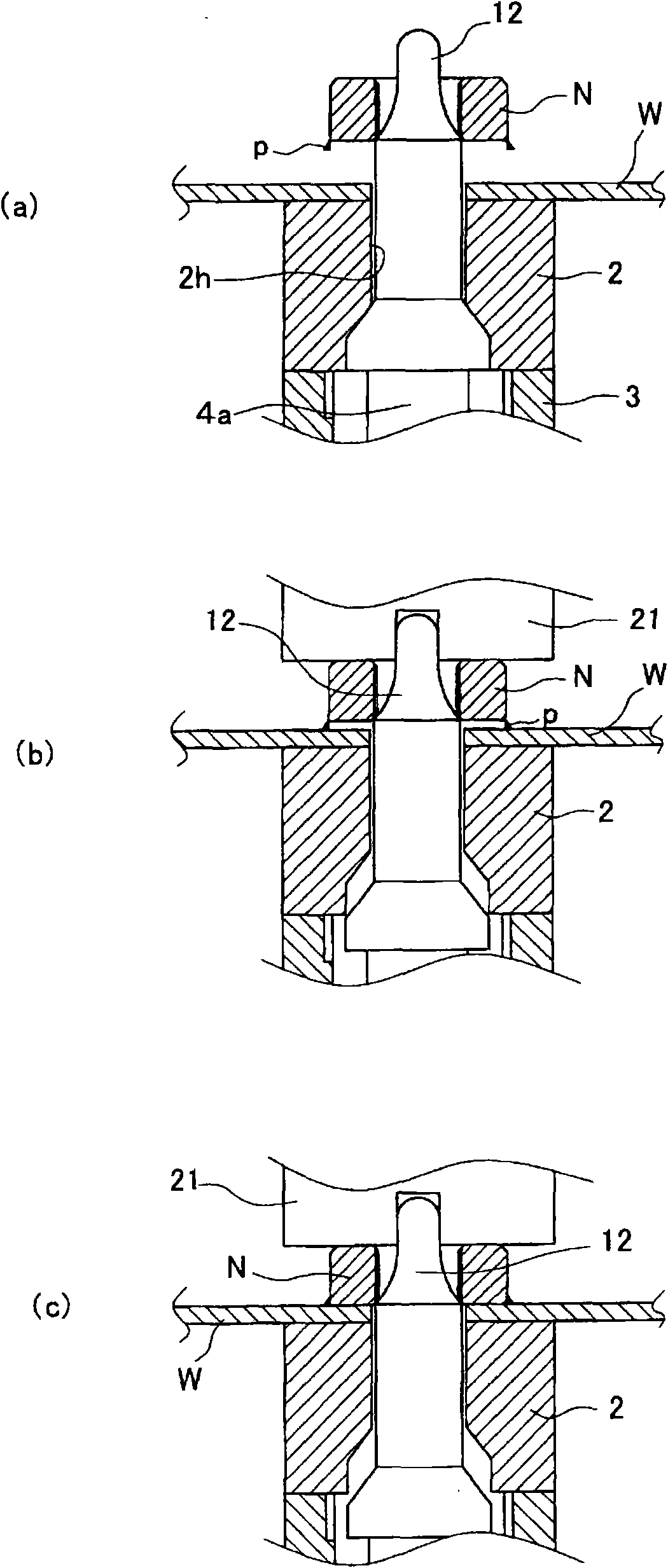

[0028] Embodiments of the present invention will be described with reference to the drawings.

[0029] The lower electrode device for welding according to the present invention is characterized in that the structure of the device is simplified to achieve compactness of the whole device, and it is possible to accurately judge defects during welding. The air cylinder unit and other components are used to assist the spring force by the air pressure used to prevent foreign matter from intruding into the electrode clamp tube.

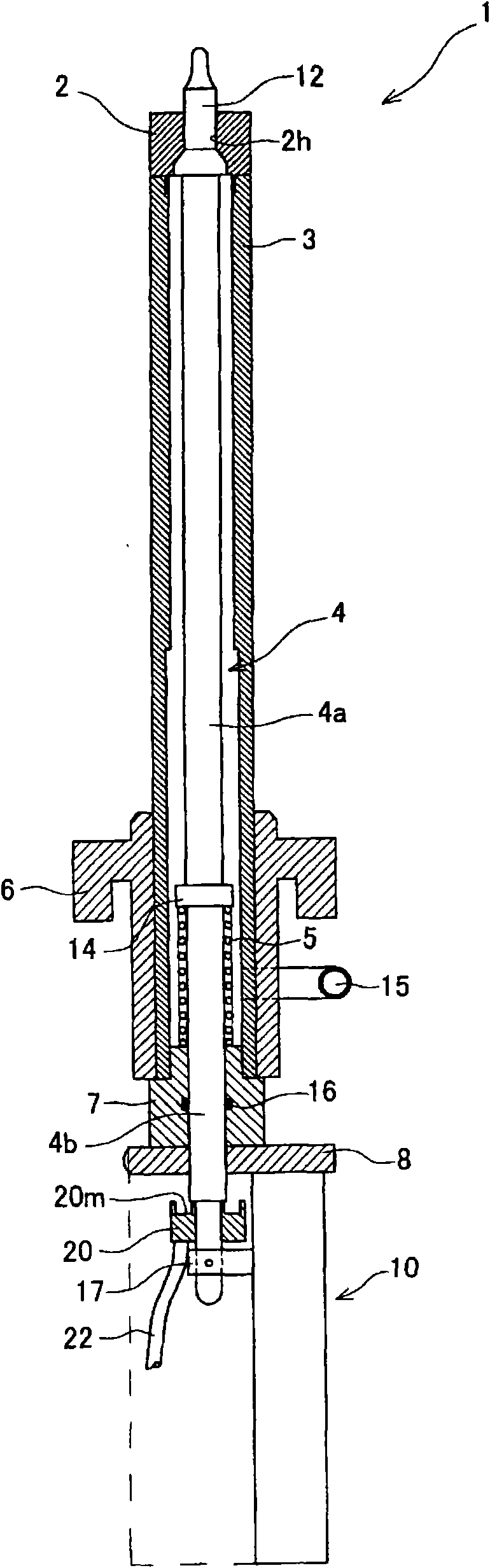

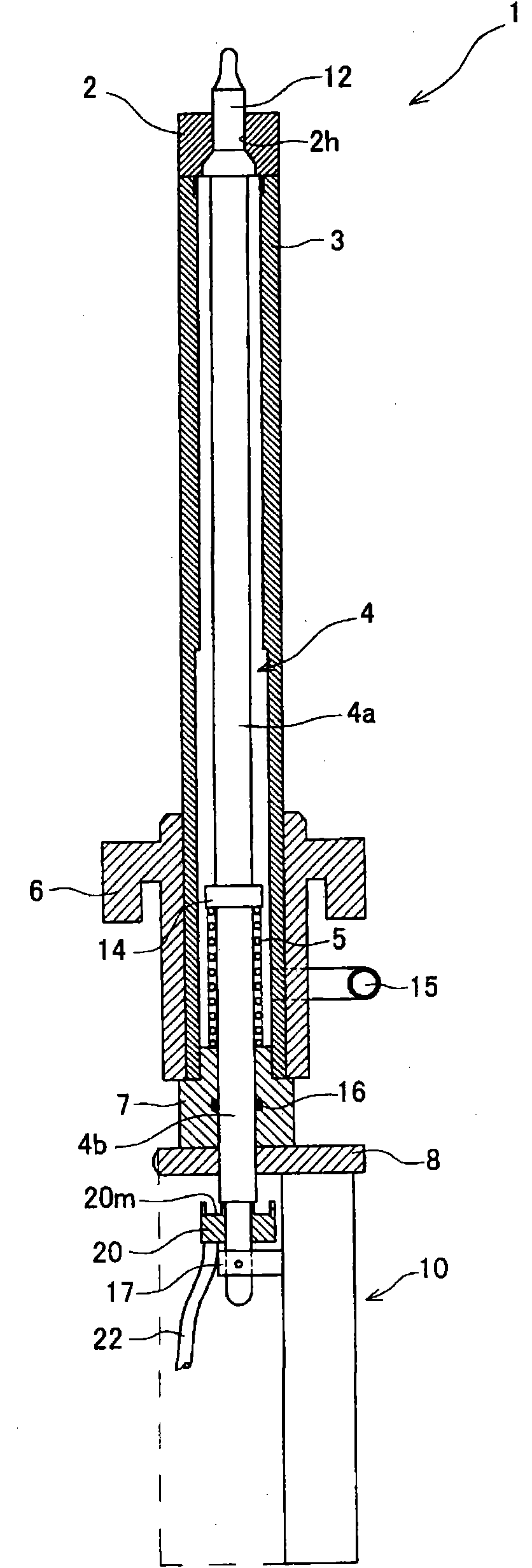

[0030] That is, if figure 1 As shown, the lower electrode device 1 for welding of the present invention includes an electrode clamping tube 3 screwing the lower electrode 2, a rod 4 that can be lifted and lowered inside the electrode clamping tube 3, and a spring 5 that applies force to the rod 4 upwards. A water supply and drainage unit 6 is arranged at the lower end of the above-mentioned electrode clamp tube 3, and the water supply and drainage unit 6 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com