Display device defect detecting method and display device defect detecting device

A technology for display device and defect detection, which is applied in the testing, measuring device, and identification device of machine/structural components, etc., and can solve problems such as non-judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

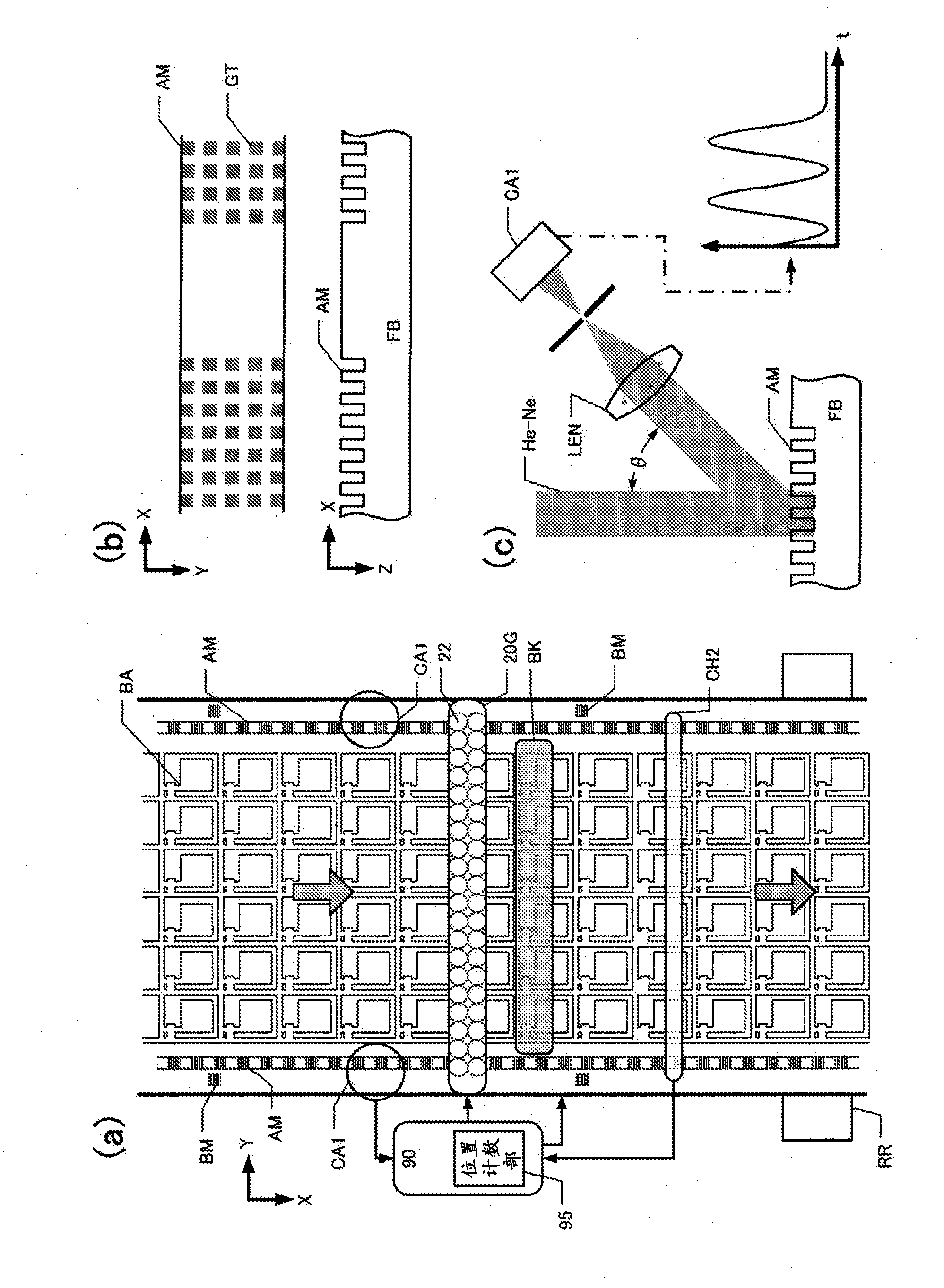

[0038] The manufacturing apparatus of the display element demonstrated in this embodiment mode is an apparatus applicable to an organic EL element, a liquid crystal display element, or a field emission display. The manufacturing apparatus and manufacturing method of an organic EL element are demonstrated as a representative example.

[0039] "Manufacturing device of organic EL element"

[0040] In the manufacture of an organic EL element, it is necessary to prepare a substrate on which thin film transistors (TFTs) and pixel electrodes are formed. In order to precisely form one or more organic compound layers (light-emitting element layers) including a light-emitting layer on the pixel electrodes on the substrate, it is necessary to form the barrier ribs BA (bank layers) easily and precisely in the boundary region of the pixel electrodes. .

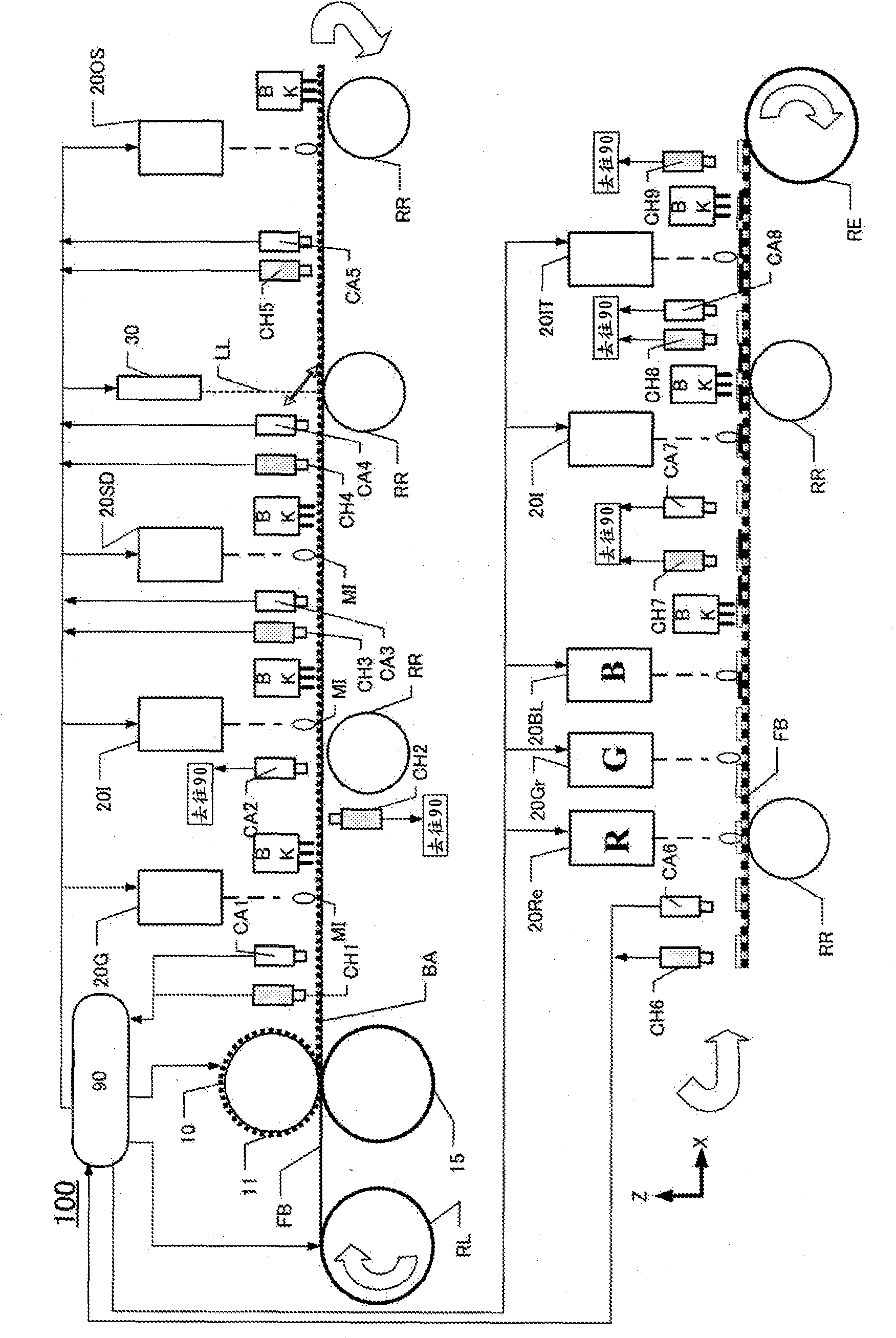

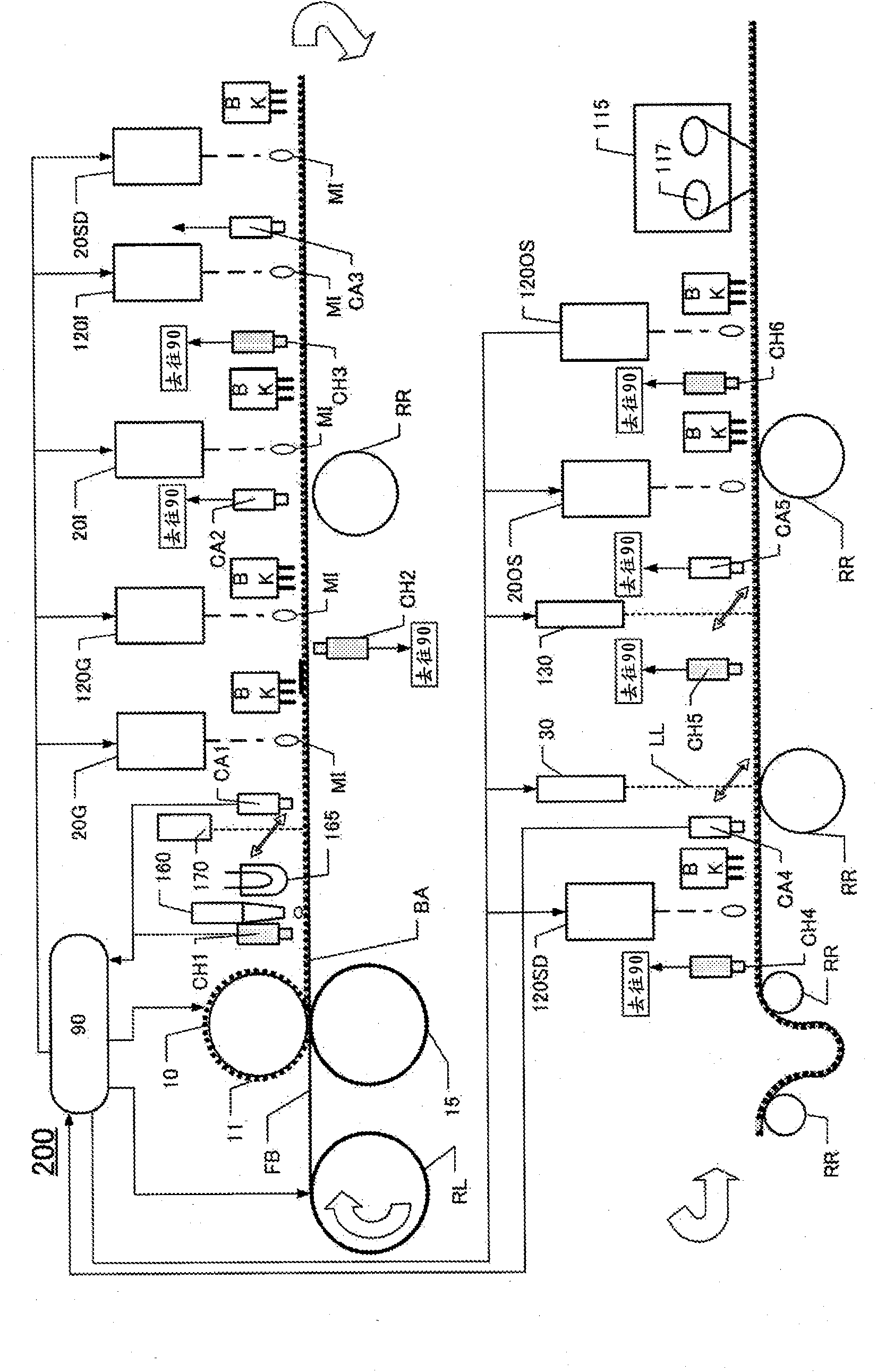

[0041] figure 1 It is a schematic diagram showing the configuration of a manufacturing apparatus 100 for manufacturing an organic EL e...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap