Micromotor commutator system

A micro-motor and subsystem technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the complex assembly process of motor rectifier sub-assemblies, affect the contact area between brush and rotor commutator, commutator and coil Small and other problems, to achieve the effect of reducing assembly cost, not easy to deform, and canceling the clamping process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

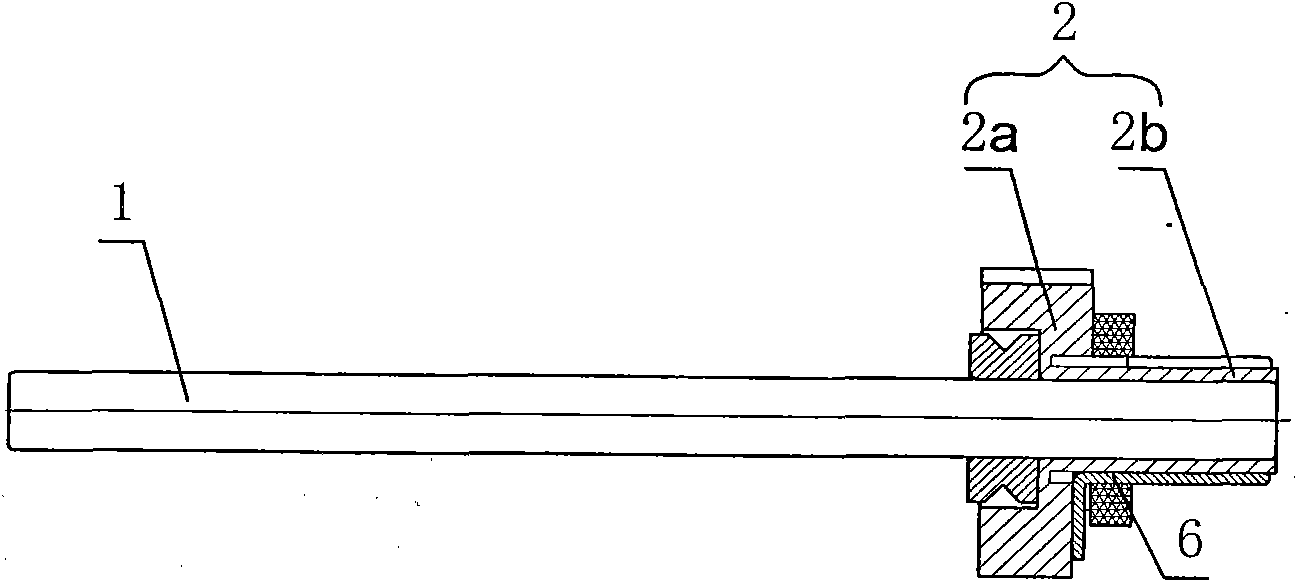

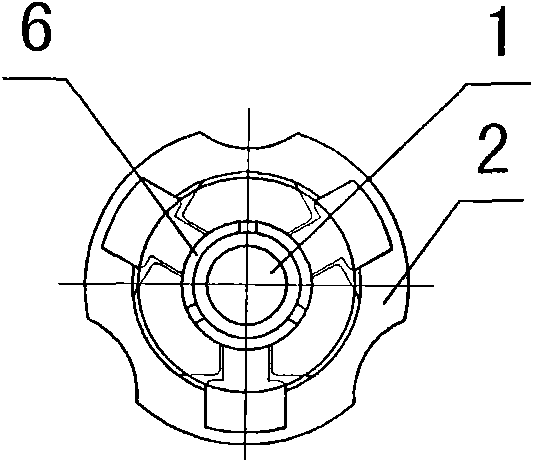

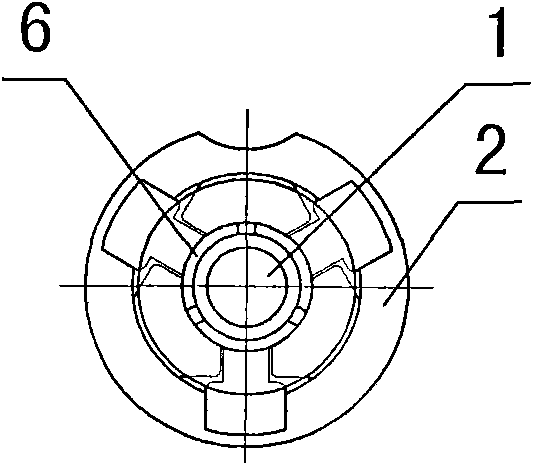

[0040] Such as Figure 4 , 5 Shown: a micro-motor rectifier subsystem, including a main shaft 1 and a commutator 2, the commutator 2 is provided with a large-diameter section 2a and a small-diameter section 2b, wherein the large-diameter section 2a is bonded to the inner wall of the coil 5 Together, three conductive sheets 6 are evenly fixed on the outer wall of the small-diameter section 2b, and the three conductive sheets 6 are in contact with the brushes 4. It is characterized in that: the commutator is injection-molded on the main shaft 1, and the side wall of the main shaft 1 There is a fixing groove, and the inner wall of the commutator 2 is injection-molded with a limiting protrusion 2c, which is adapted to the shape of the fixing groove, and the limiting protrusion 2c is located in the fixing groove;

[0041] Such as image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com