Multi-section centering self-rotating reducer oil pipe pump

A technology of rotation change and oil pipe, which is applied to variable capacity pump parts, pumps, pump components, etc., can solve the problems of affecting production, increasing operating costs, and large downward resistance of plungers, etc., and achieves wide application range and long service life , Great lifting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

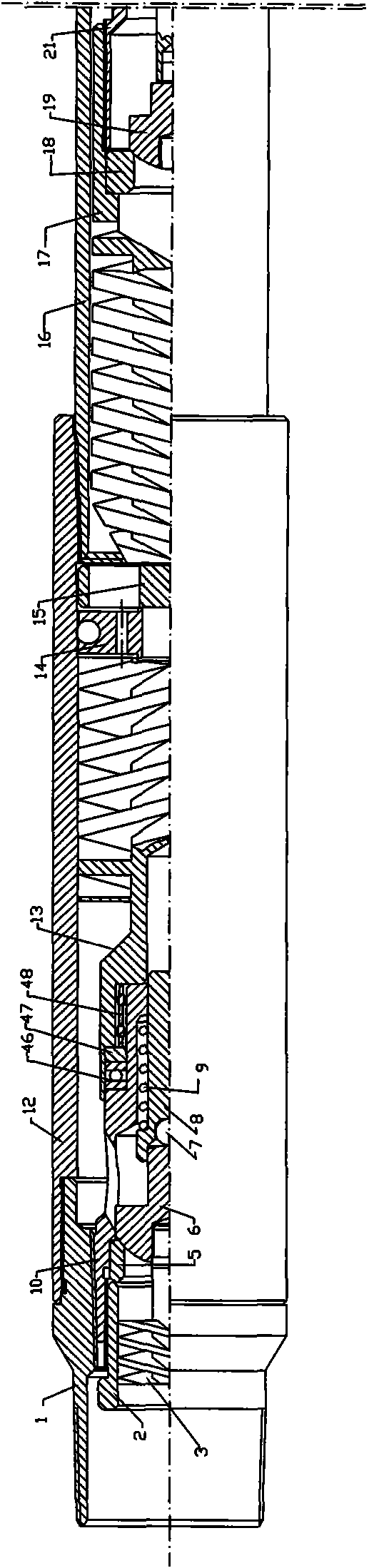

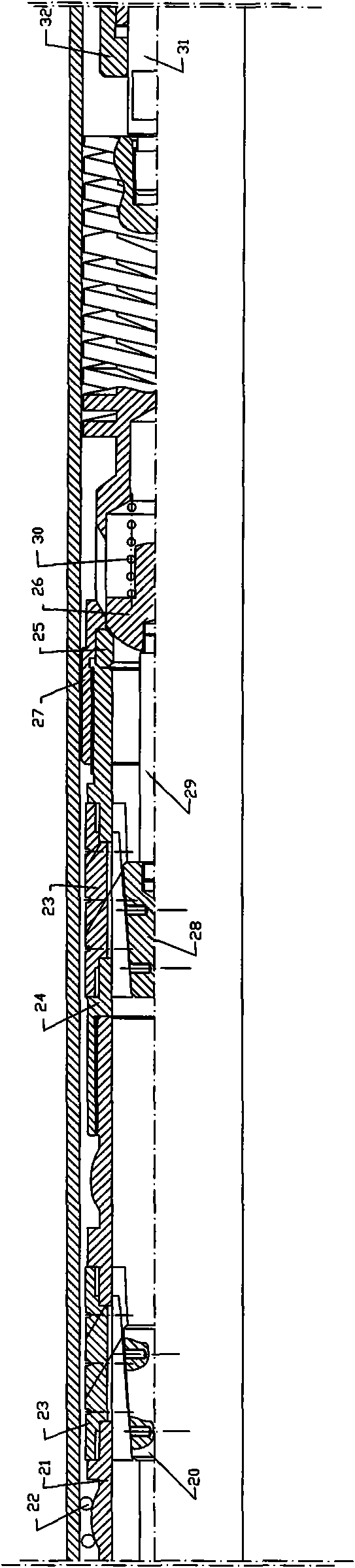

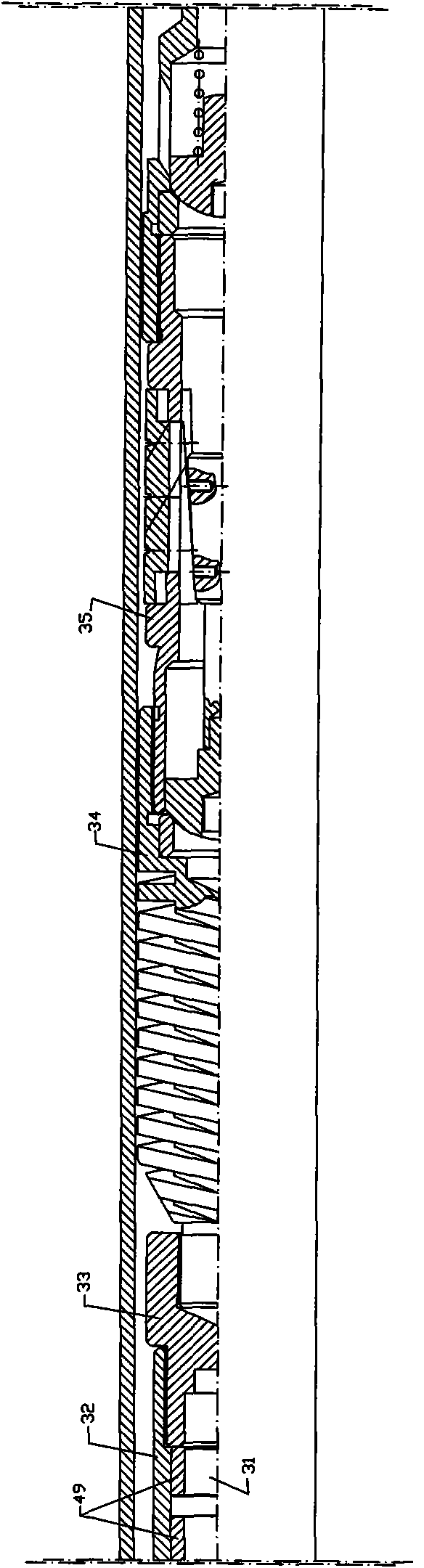

[0069] Depend on Figure 1a , Figure 1b , Figure 1c and Figure 1d The four segments are added and combined into an overall structure diagram, such as Figure 1a , Figure 1b , Figure 1c and Figure 1d As shown, the multi-section, centering, self-rotating and variable-diameter tubing pump of the present invention uses the integral tubing 16 as the central pump barrel, and the pump barrel has upper and lower joints 45, 12, thereby forming the inner chamber of the pump barrel, which is composed of From bottom to top, there are sand-proof buried rotary hemispherical fixed valve assembly, a set of plunger assembly unit, upper thruster, rotator and anti-collision mechanism in sequence.

[0070] The structure of the present invention is introduced successively from bottom to top below:

[0071] see Figure 1a , there is a tailpipe joint 1 screwed on the outer end of the lower joint 12 of the pump barrel. The structure of the tailpipe joint 1 can be found in figure 2 , the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com