Integrated shearing and bent reshaping clamp device of optical device pin

An optical device and pin technology, applied in the field of optical communication production and processing, can solve the problems of device pin root damage, high personnel skill requirements, poor consistency, etc., to reduce the risk of damage, low employee skill requirements, and reduce production. The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

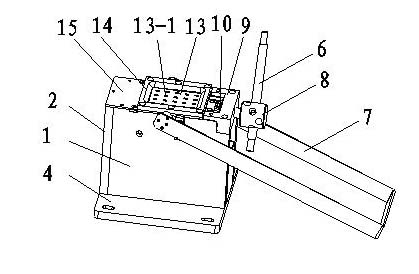

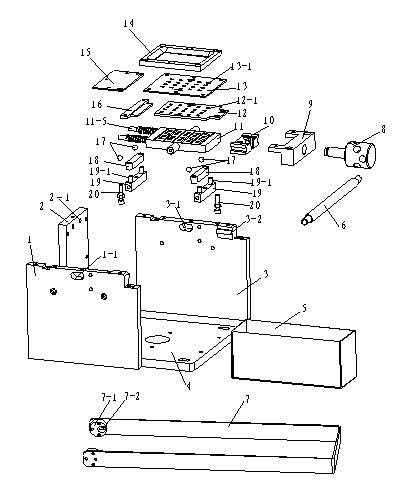

[0024] like Figure 1-9 As shown, an optical device pin cutting and bending shaping jig integrated device, including a hollow square surrounded by the left side plate 1, the right side plate 3, the vertical plate 2 and the base 4, which is the supporting overall structure The important components, and the rest of the components are based on this hollow square. The collection box 5 is placed in the hollow box and below the knife plate 11, and is mainly used to collect the redundant pins that have been cut. The oblong hole 1-1 provided above the left side plate 1 corresponds to the oblong hole 3-1 provided above the right side plate 3, and the left side plate 1 and the right side plate 3 are located in the oblong hole 1-1 , Both sides of the oblong hole 3-1 are respectively connected with a support member 19 by screws, and the support member 19 is provided with two cylinders 19-1 matching the cylindrical holes on the top block 18, and the top block 18 passes through the two Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com