Coordinated loading device

A material storage and feeding machine technology, applied in the field of feeding devices, can solve the problems of irregular placement of materials, inconvenient processing and production, and troubles, and achieve the effects of convenient heating operation, avoiding accidents, and firm and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

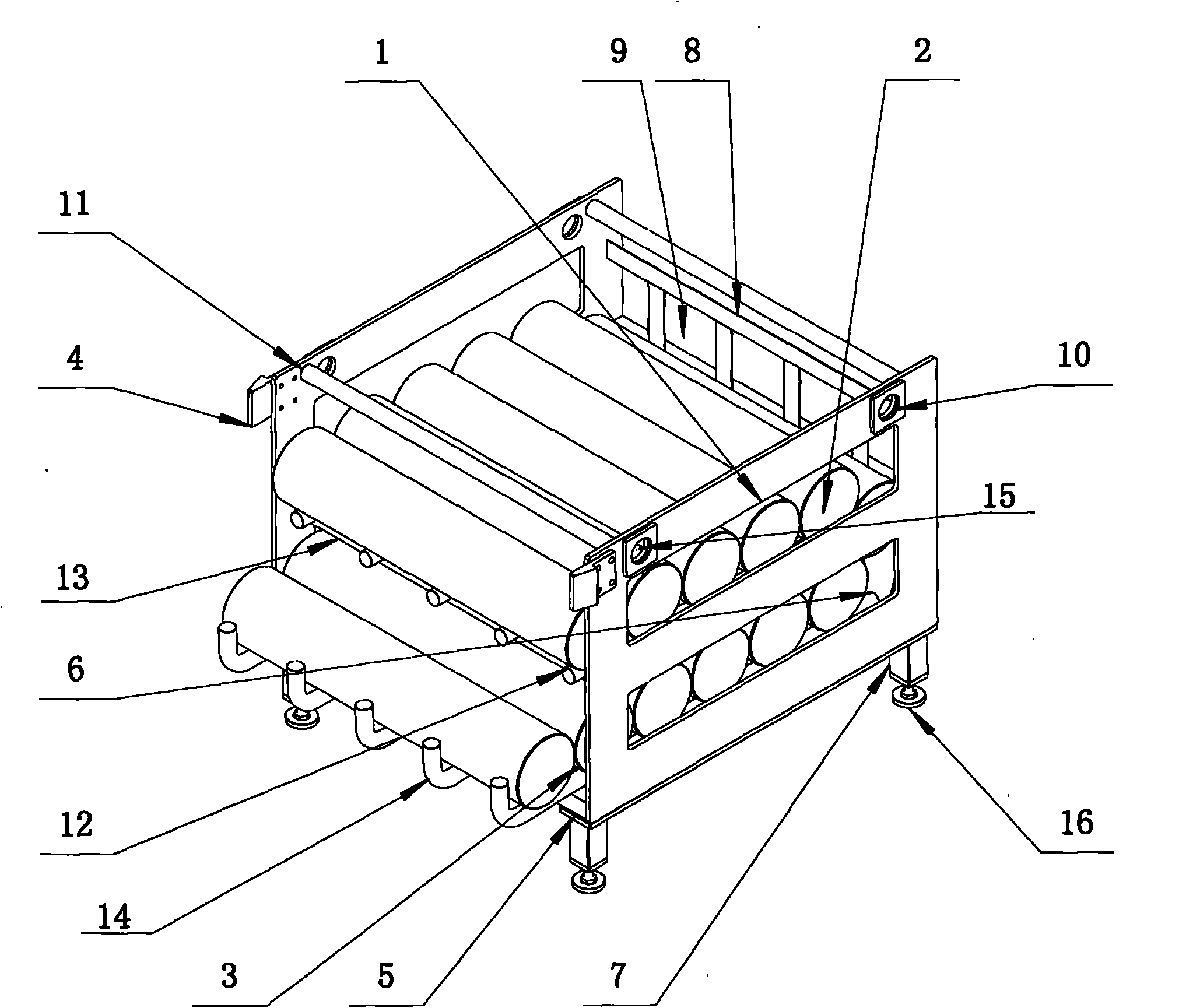

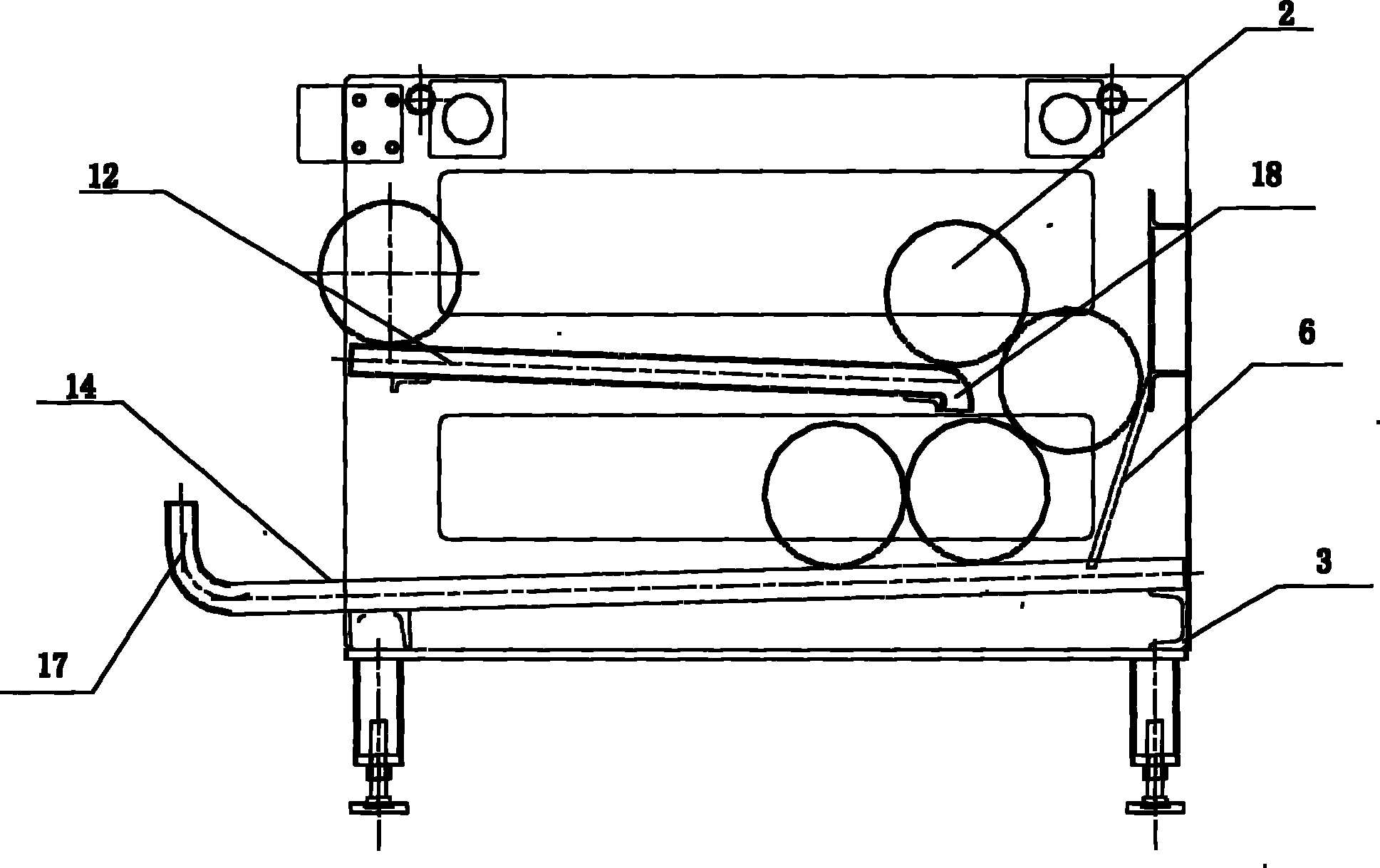

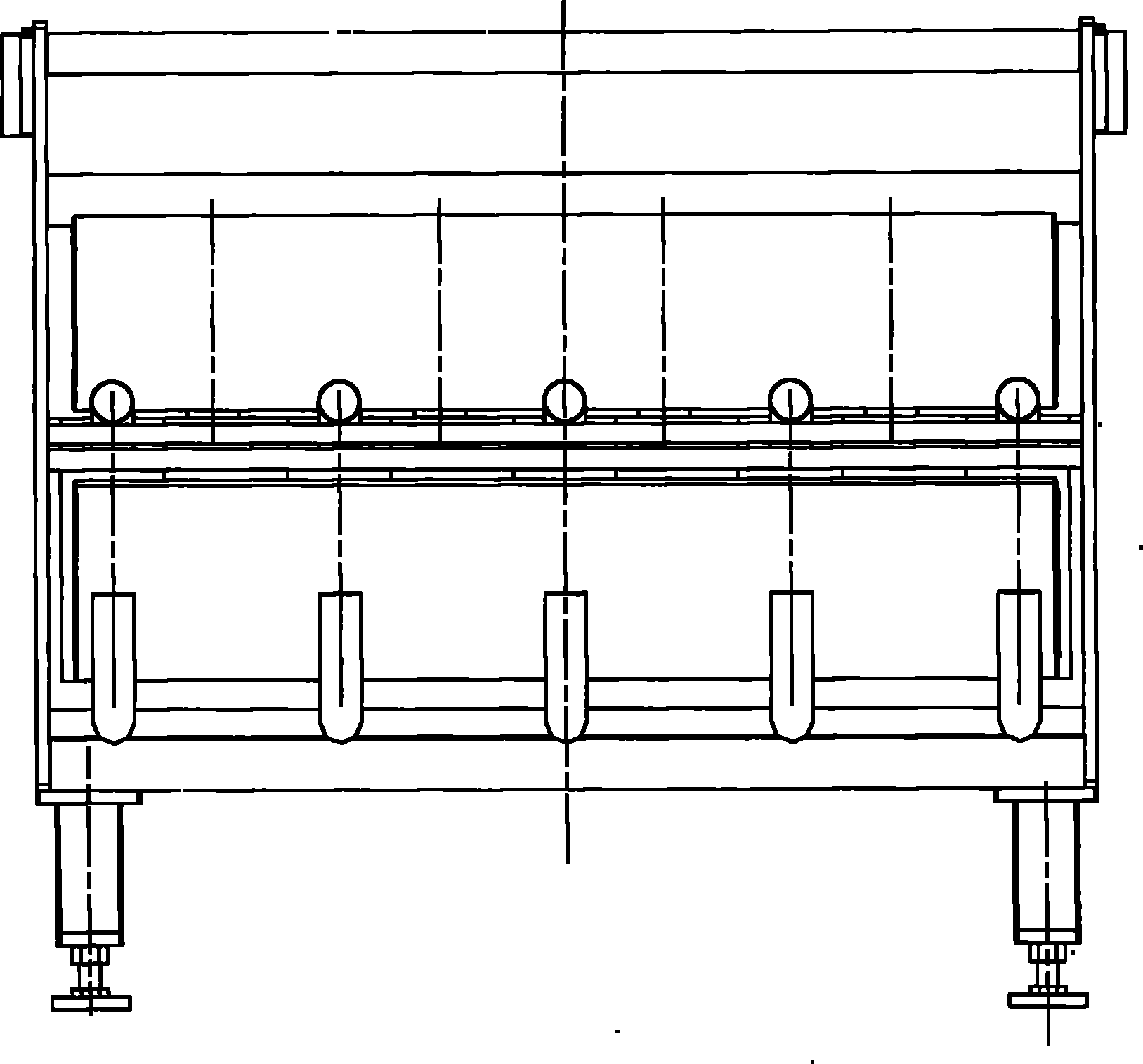

[0033] Such as figure 1 , figure 2 , image 3 As shown, the unpowered material storage device includes a material storage frame made up of left and right side plates 1, bottom plate 5 and rear baffle 9, and the left and right side plates 1 and the rear baffle 9 are provided with hollows, so that they can be used during operation. It is convenient for the operator to observe the situation inside the storage box, so as to achieve correct and safe operation. A middle plate 13 is arranged between the left and right side plates 1 in the middle of the material storage frame, the middle plate 13 is inclined to the inside of the material storage frame, and there is a gap between the middle plate 13 and the rear baffle plate 5, in order to make the material storage frame can be separated For layer use, put more materials. Five upper retaining pipes 12 are arranged on the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com