Package glue film opening split line opening knife module

A film and die-cutting technology, applied in metal processing, etc., can solve problems such as increased processing costs, long time spent on parts, and low technology utilization, so as to save time spent, reduce processing costs, and contribute to industrial benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments adopted by the present invention will be further described by the following embodiments and accompanying drawings.

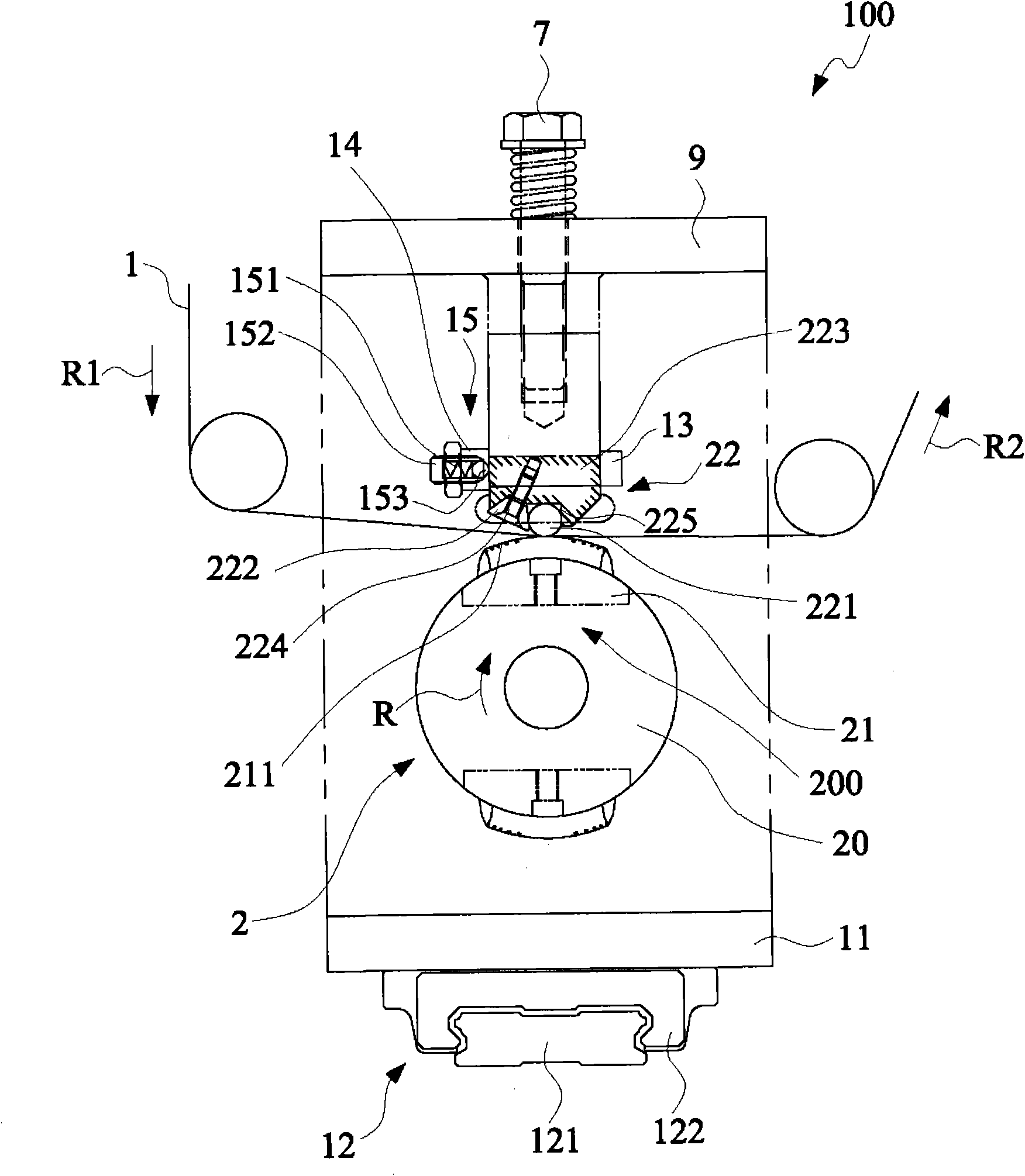

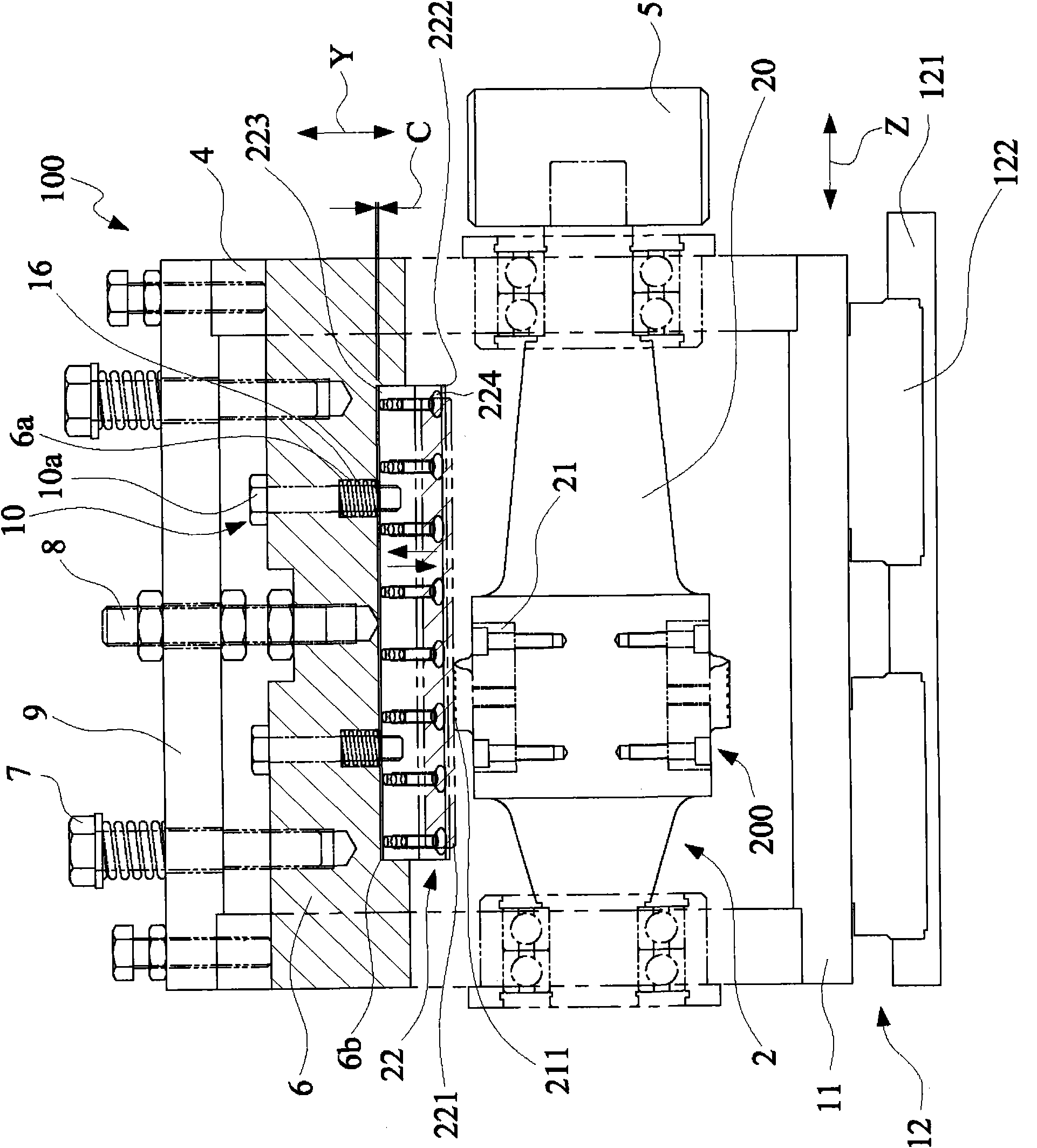

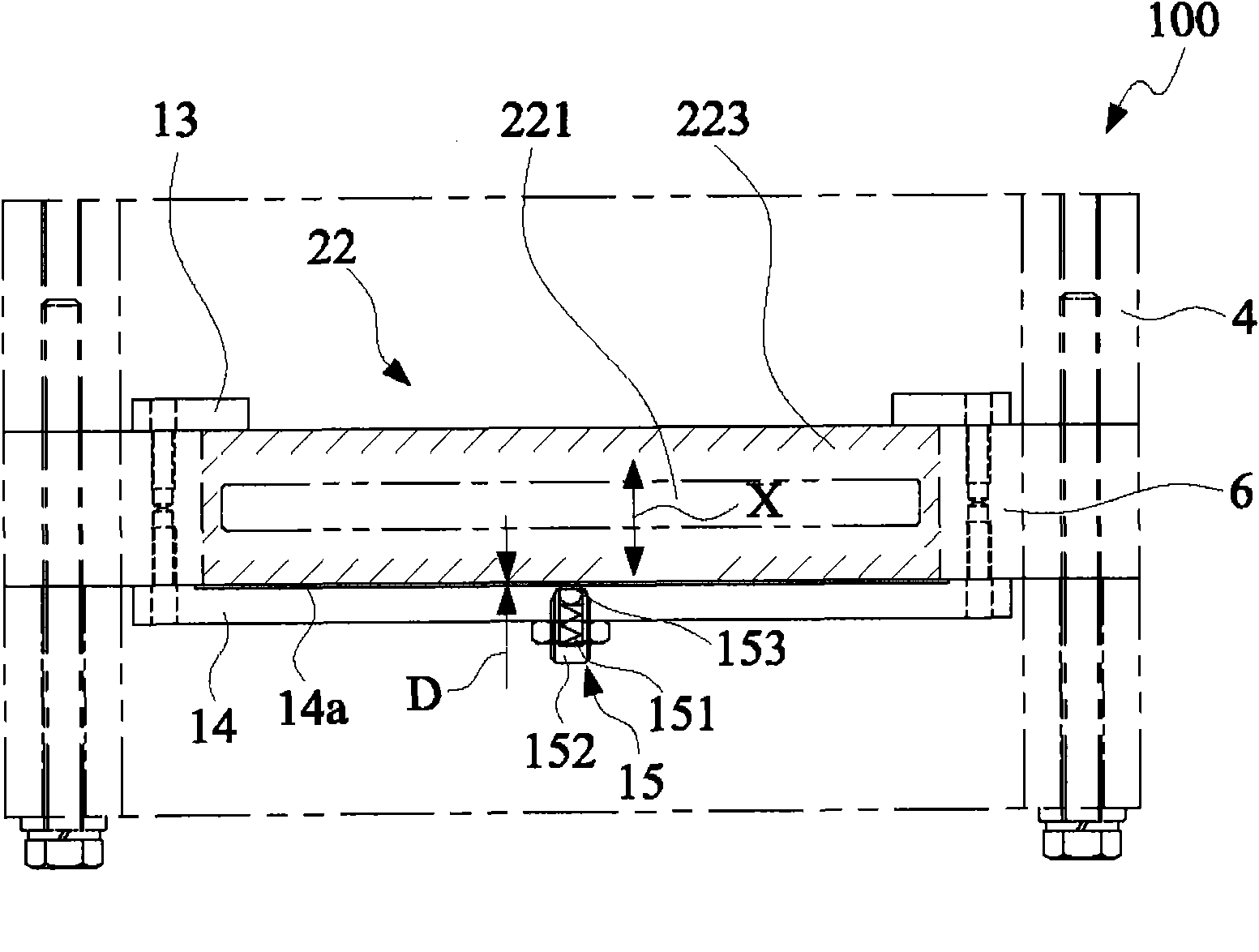

[0026] see also figure 1 and figure 2 as shown, figure 1 It is a schematic side view plan view showing the rolling mechanism of the opening crack line of the packaging film, figure 2 It is a schematic front view showing the rolling mechanism of the opening crack line of the packaging film. As shown in the figure, the packaging film opening crack line rolling mechanism 100 includes a set of base frames 4, a support frame 6, at least one locking bolt 7, a top plate 9, a pressure bearing unit 22, and an impact force buffer mechanism 10 and an opening knife module 2. Wherein the top plate 9 is combined with the base frame 4 , and the locking bolt 7 is combined with the supporting frame 6 through the top plate 9 .

[0027] The pressure unit 22 includes a pressure seat 223 , a cutter roller 221 and a pressure plate 222 , and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com