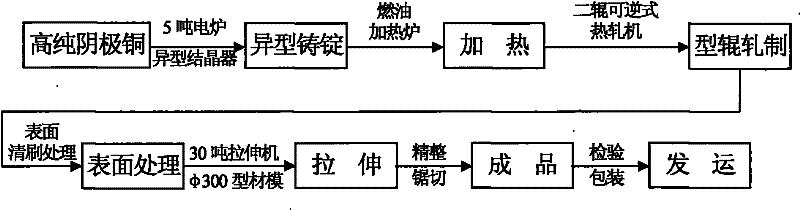

Preparation process of special solid conductive plate and bus board for electrolysis

A preparation process and technology of conductive plates, which are applied in manufacturing tools, metal rolling, metal rolling, etc., can solve the problems of poor forming accuracy, small specifications of conductive plates and collector plates, etc. The effect of straightness control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

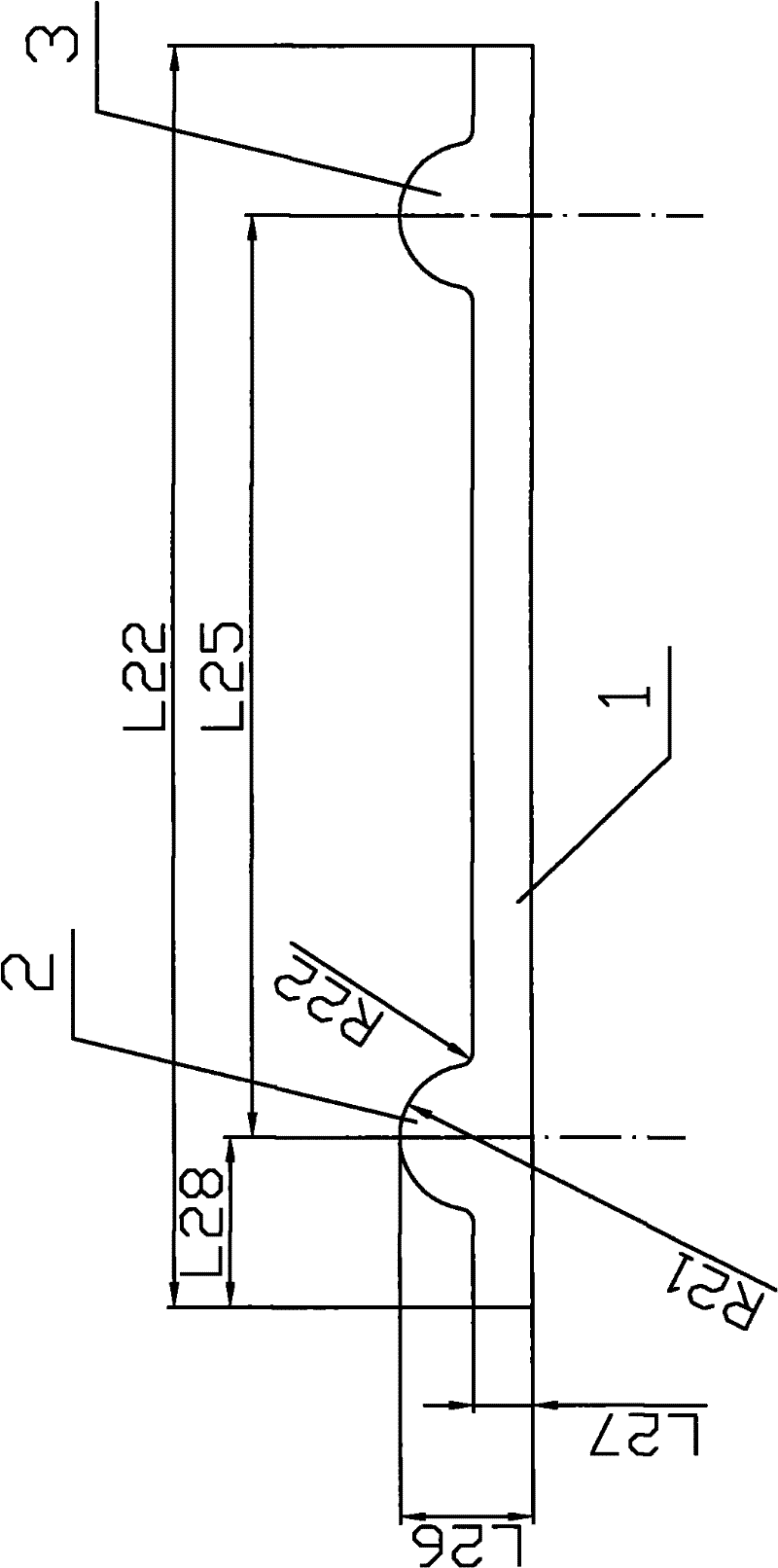

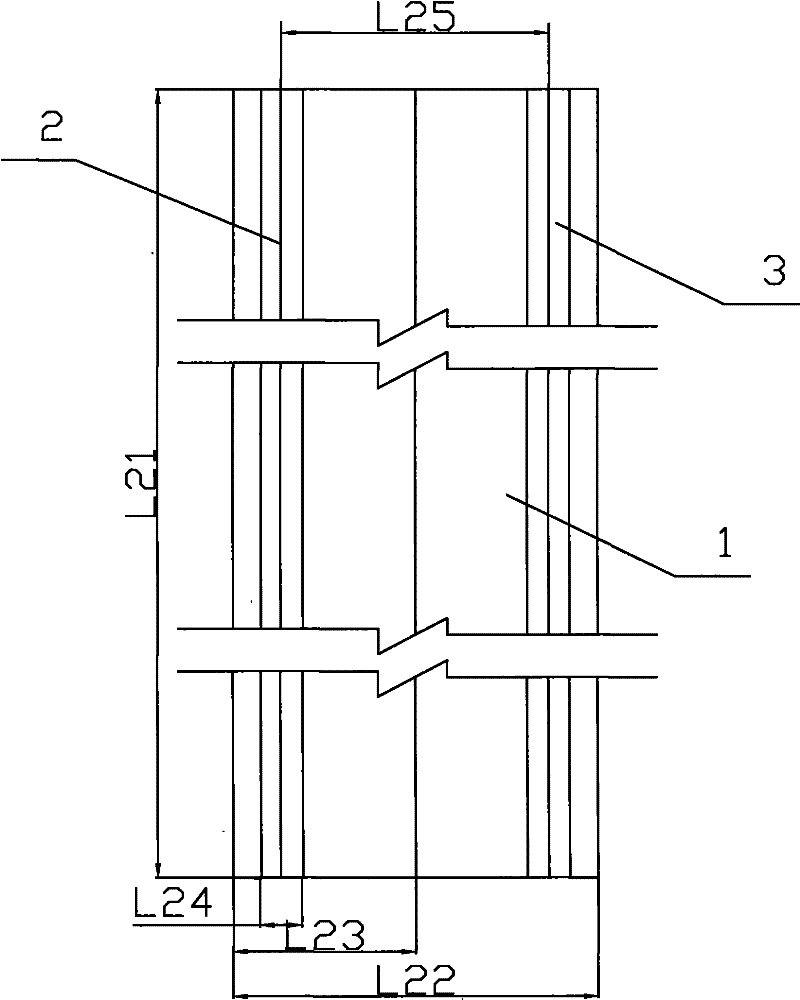

[0034] As shown in Fig. 2 (a)-(b), electrolysis among the present invention is with special-shaped solid copper conductive plate structure and size as follows:

[0035] Two solid conductive ribs are arranged on the conductive substrate 1: conductive rib I2 and conductive rib II3, the two conductive ribs are arranged in parallel, and the shape of the conductive rib is arc-shaped. In the picture:

[0036] The length L21=5700mm of the conductive substrate 1, the width L22=260mm of the conductive substrate 1, the distance L23=130mm from the centerline of the conductive substrate 1 in the width direction to the side of the conductive substrate 1, the width L24=30mm of each conductive rib, two The centerline spacing L25=190±0.5mm of the conductive ribs, the height L26=25±0.5mm of each conductive rib, the thickness L27=12mm of the conductive substrate 1, the longitudinal centerline of each conductive rib is apart from the conductive substrate 1 side ( That is: the distance L28=35mm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com