Tyre safety rubber coating mechanism

A tire and safety technology, which is applied to devices and coatings that apply liquid to the surface, can solve the problems of complex mold shapes, high manufacturing costs, laborious and time-consuming construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

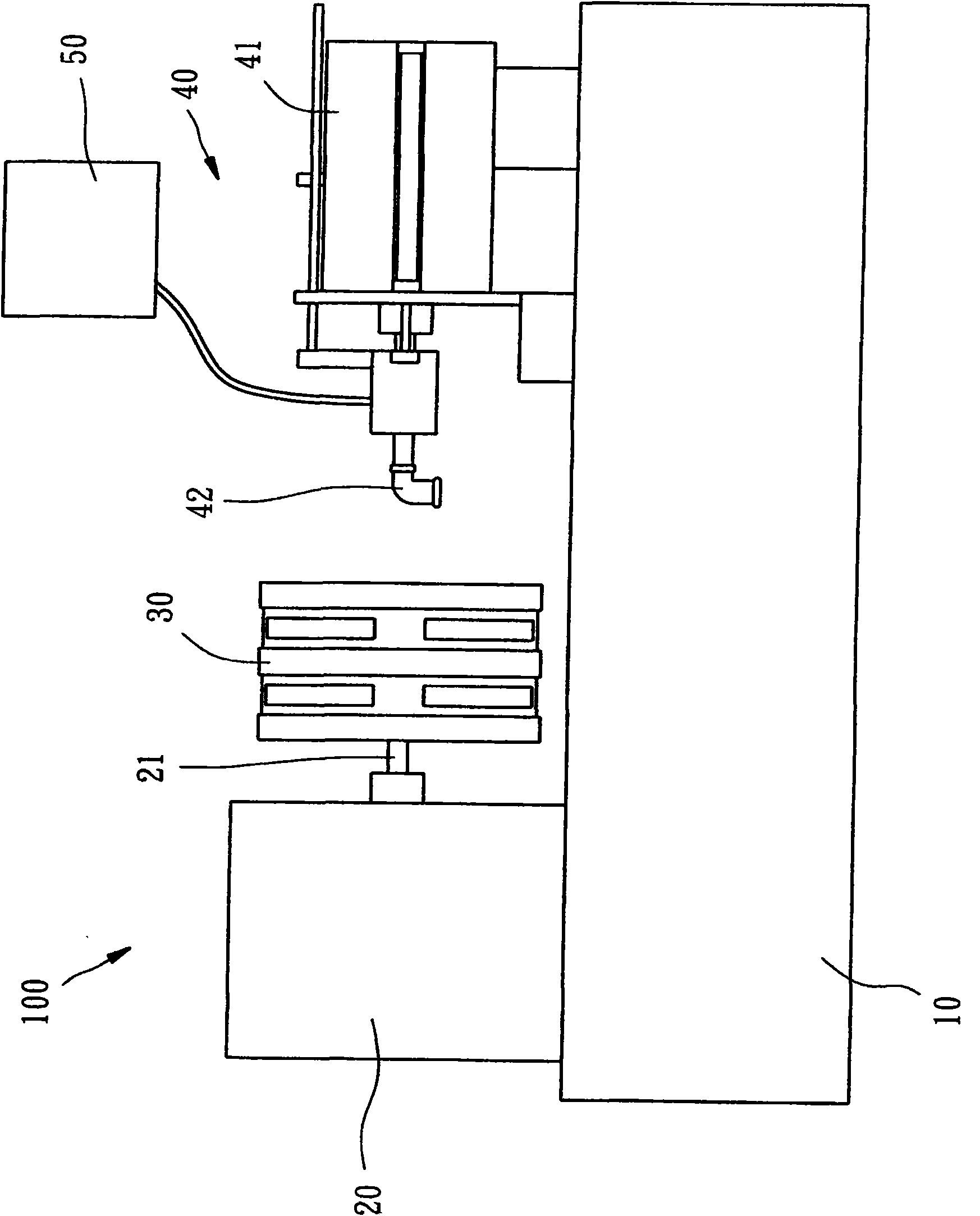

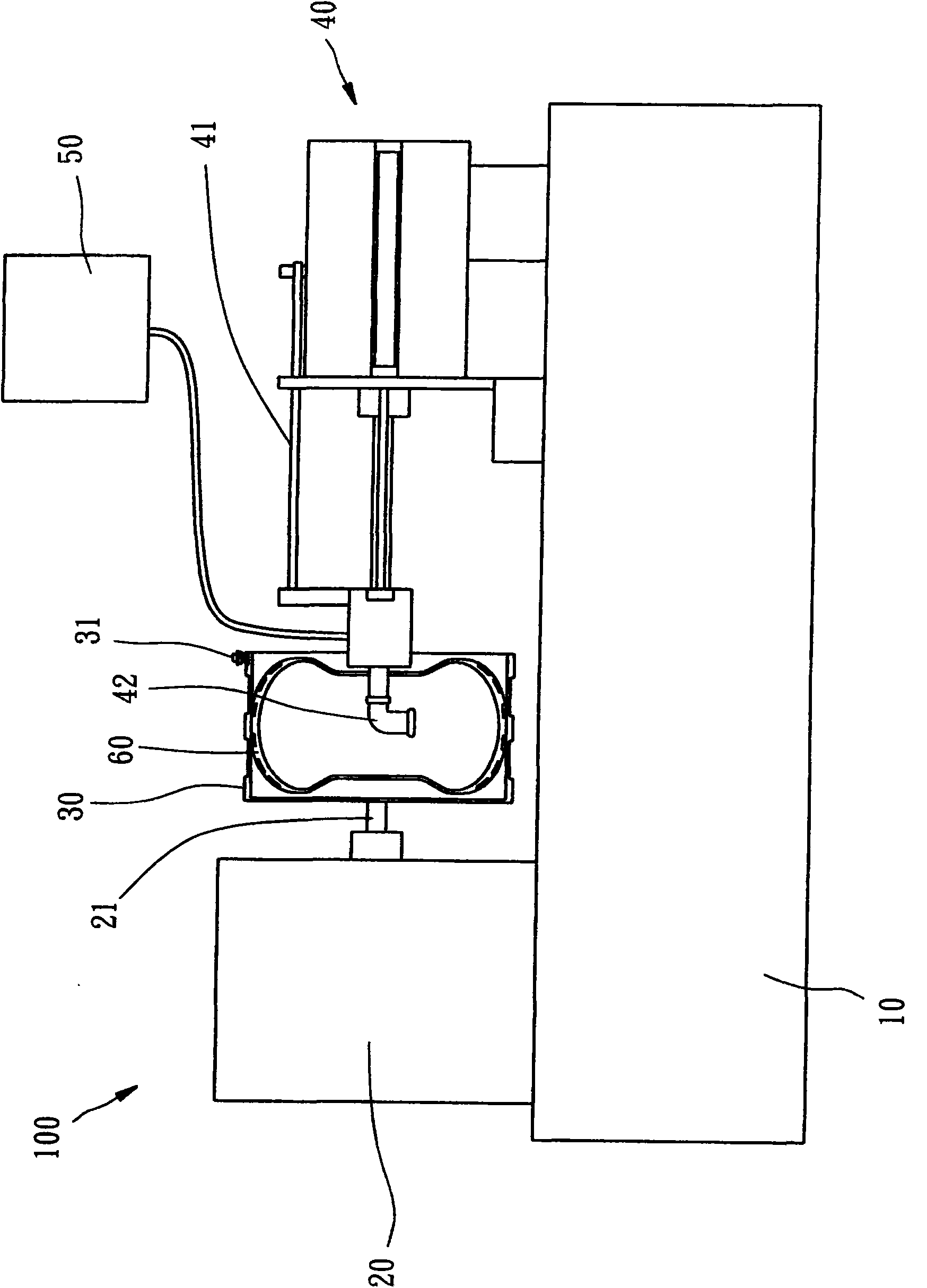

[0014] see figure 1 , is a tire safety rubber coating mechanism 100 provided by a preferred embodiment of the present invention, which mainly includes a machine 10, a rotating device 20, a mold 30, a coating device 40 and a heating storage device 50 ;in:

[0015] The machine platform 10 can be stably placed on a plane.

[0016] The rotating device 20 is a motor assembly fixed on the machine table 10 and has an output shaft 21 that can rotate at a predetermined speed.

[0017] The mold 30 is roughly a circular frame, fixedly connected to the output shaft 21 of the rotating device 20 , and can be driven by the rotating device 20 to rotate coaxially with the output shaft 21 .

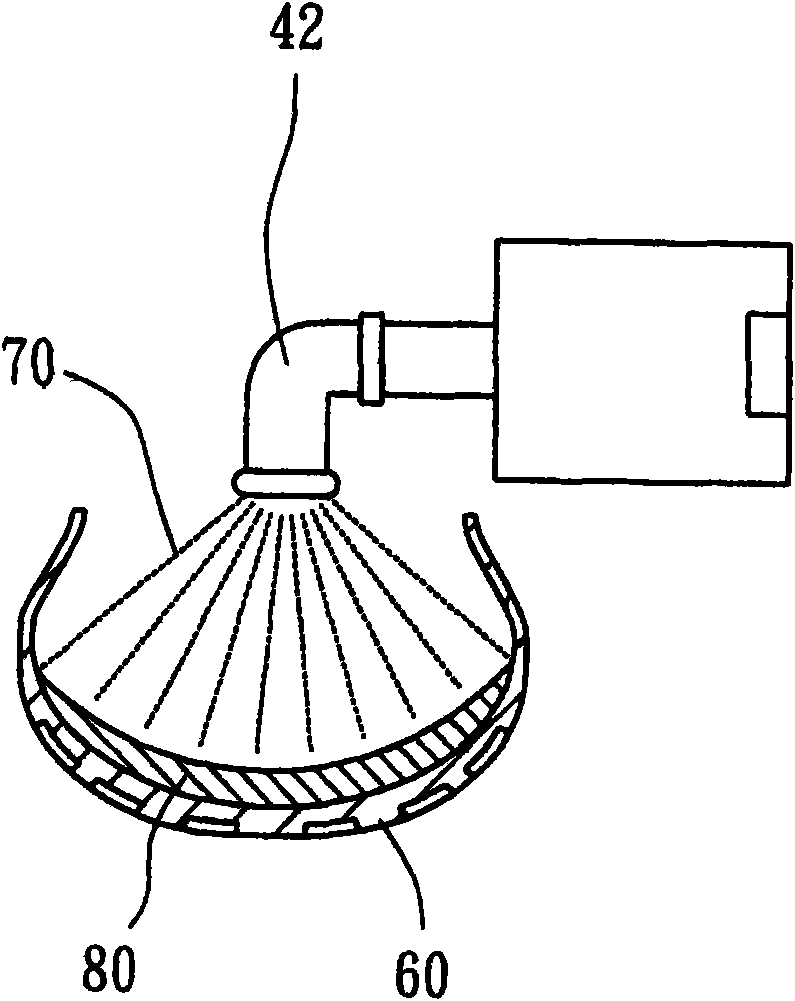

[0018] The coating device 40 has a reciprocating displacement assembly 41 and a spray head 42. The reciprocating displacement assembly 41 is arranged on the machine platform 10 and can be moved from a first position to a second position along the machine platform 10. The spray head 42 is fixed on the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com