Calking appliance and manufacturing method for fluid processor

A manufacturing method and processor technology, applied to chemical instruments and methods, suction devices, semi-permeable membrane separation, etc., can solve the problems of wasting sealants and increasing the usage of sealants, and achieve the goal of reducing usage and reducing production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

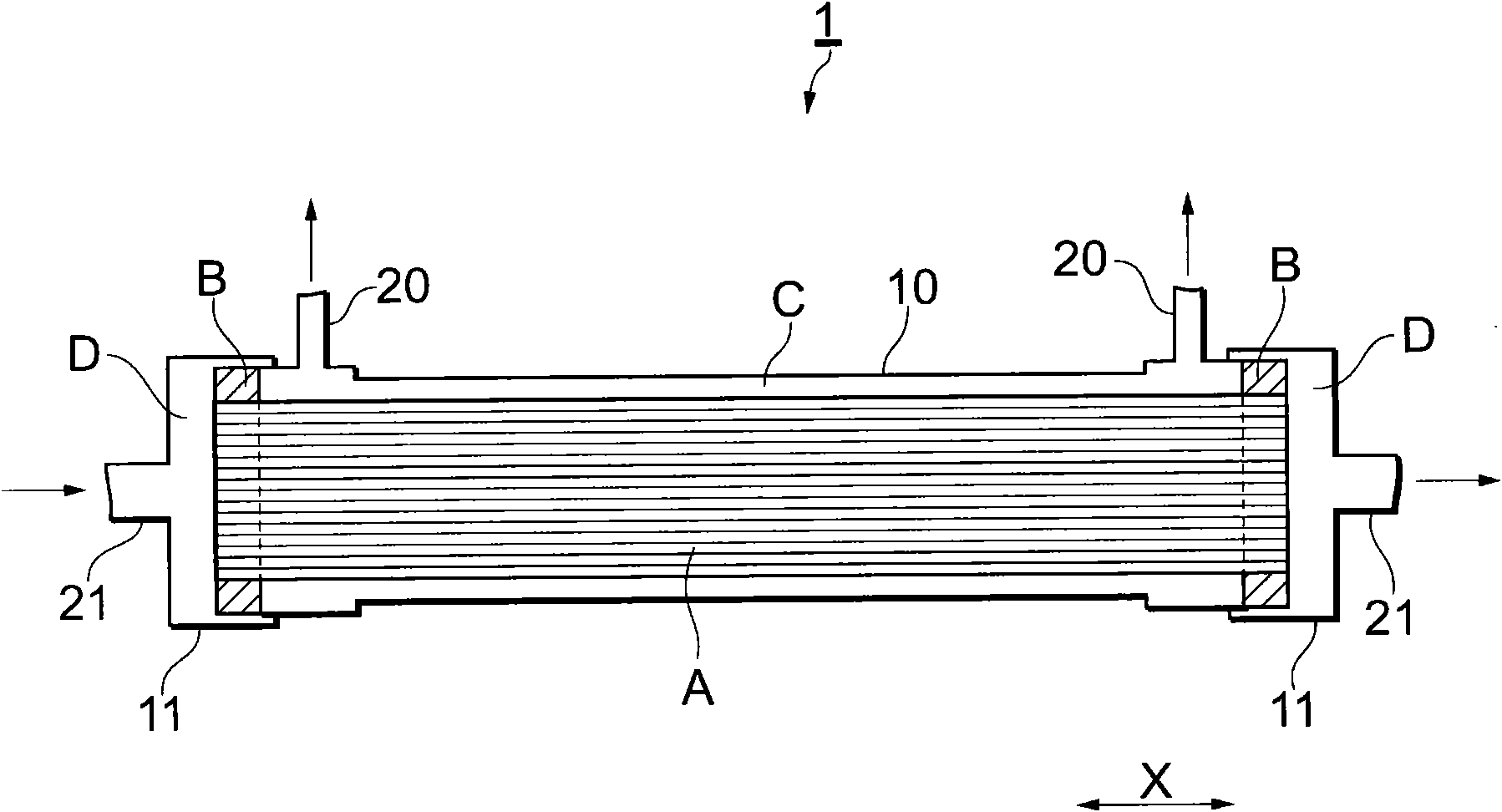

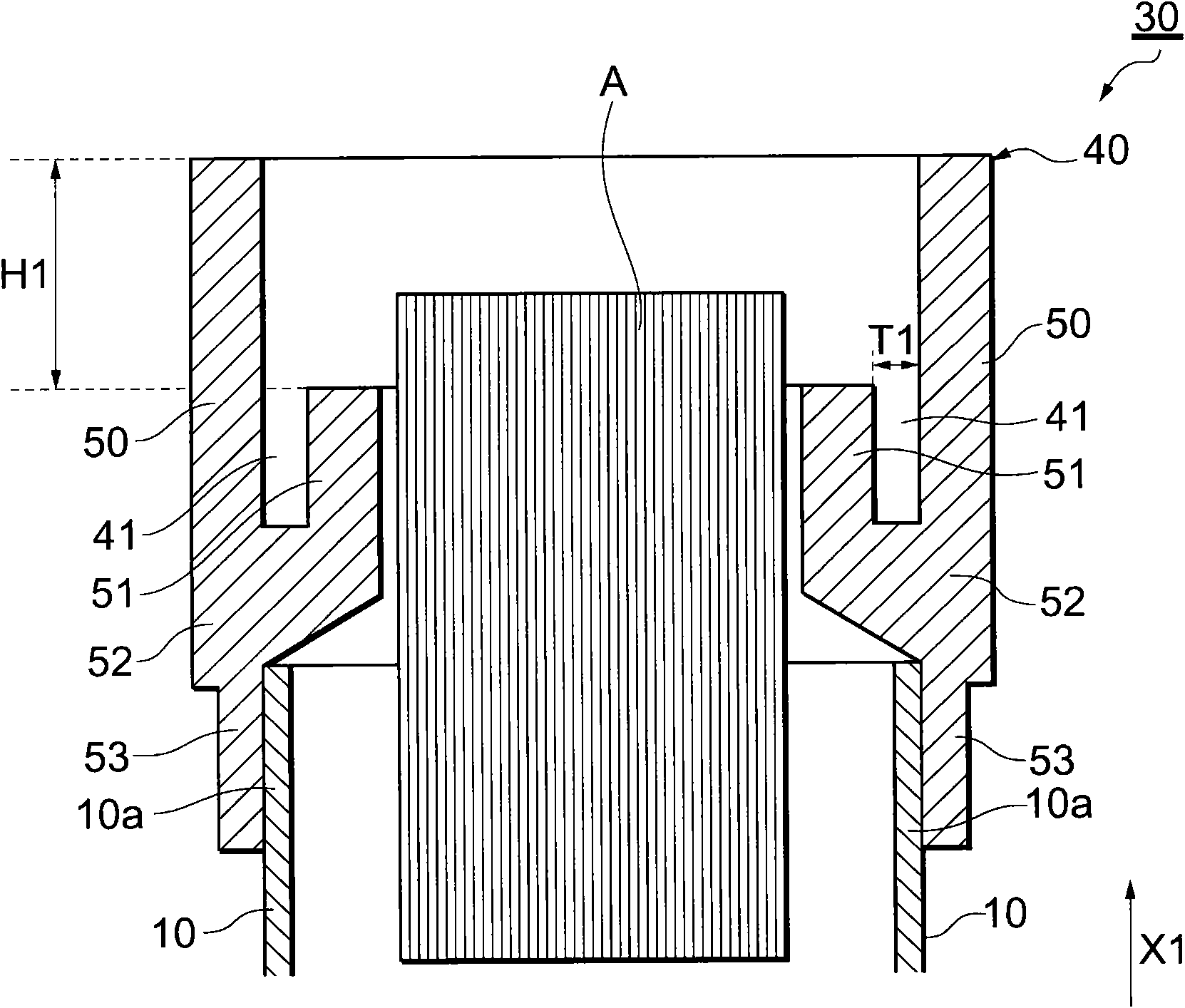

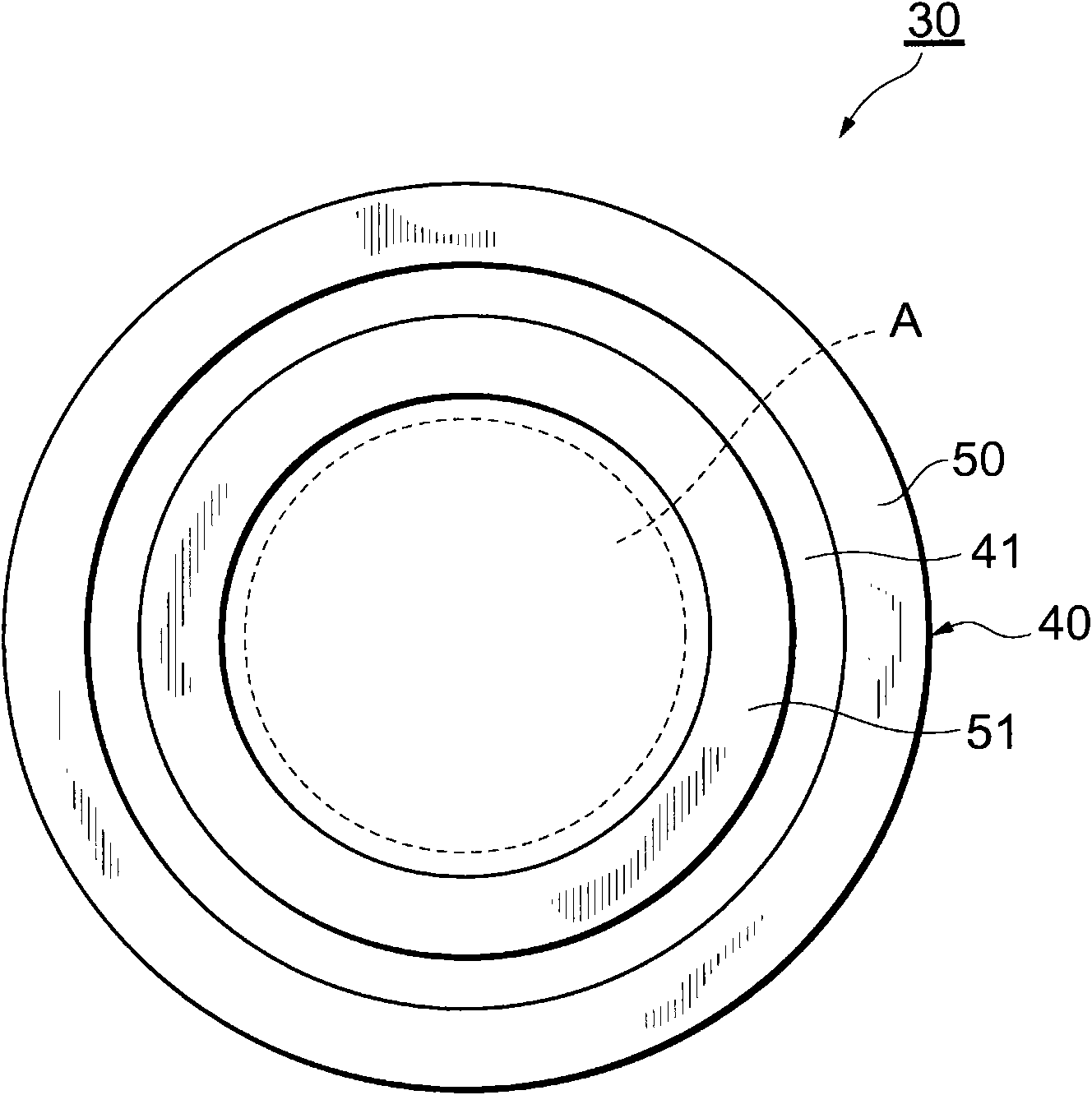

[0084] 10,000 (±500) polysulfone hollow fiber membranes with an outer diameter of 255 μm were bundled to prepare a hollow fiber membrane bundle with a diameter of 45 mm and a length of 305 mm. As the cylindrical portion, a polystyrene resin container having a total length of 286 mm was provided with two nozzles (fluid passing portions) for inflow / outflow of fluid near both ends. like figure 1 As shown, the height difference H1 between the end surface of the inner cylinder part and the end surface of the outer cylinder part made of polypropylene is 8.0 mm (the height from the bottom surface of the groove to the end surface of the outer cylinder part is 11.0 mm, and the height from the bottom surface of the groove is 11.0 mm. The height to the end surface of the inner cylinder part is 3.0mm), and the gap filling tool with the maximum groove width T1 of 3.0mm is installed on both ends of the cylindrical part, and the hollow fiber membrane bundle is loaded into the tube with the ...

Embodiment 2

[0087] Samples were produced under the same conditions as in Example 1 except that the exposed distance of both ends of the hollow fiber membrane bundle from the end face of the inner cylinder was 1.0 mm or more and the viscosity of the caulk was 8000 mmPa·s.

Embodiment 3

[0089] In addition to the fact that the exposed distance of both ends of the hollow fiber membrane bundle from the end surface of the inner cylinder is 1.0 mm or more, the viscosity of the caulk is 3000 mmPa·s, and the maximum groove width T1 is 4.0 mm. Samples were produced under the same conditions as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com