Mustard tuber production process

A production process and technology of mustard mustard, which is applied in the field of mustard mustard production and production technology, can solve the problems of mustard nutrient loss, large sewage discharge, and many process links, and achieve the effects of protecting the environment, reducing emissions, and simplifying process procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

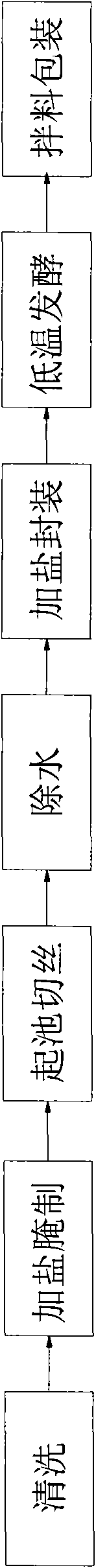

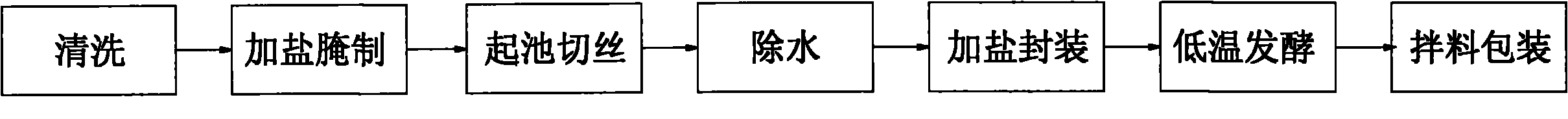

Image

Examples

Embodiment 1

[0025] (1) Cleaning: clean the harvested cabbage heads;

[0026] (2) Add salt to marinate: put the washed cabbage heads in the vegetable pool, spread a layer of salt on the cabbage heads for each layer of cabbage heads until the vegetable pool is full, add salt to the weight of the cabbage heads 1% by weight, marinated for 2 days;

[0027] (3) Shredded from the pond: remove the pickled cabbage head from the pond and shred it for later use;

[0028] (4) Dewatering: Dry the shredded cabbage in step (3) with hot air at 70°C for 2 hours to remove water;

[0029] (5) Add salt and package: add salt to the shredded vegetable after dehydration, the weight of adding salt is 3% of the shredded vegetable weight, then pack into the bag and seal;

[0030] (6) Low-temperature fermentation: put the packaged shredded vegetables in a low-temperature environment of 6°C for low-temperature fermentation for 2 months;

[0031] (7) Seasoning packaging: pack the shredded coriander seasoning marin...

Embodiment 2

[0033] (1) Cleaning: clean the harvested cabbage heads;

[0034] (2) Add salt to marinate: put the washed cabbage heads in the vegetable pool, spread a layer of salt on the cabbage heads for each layer of cabbage heads until the vegetable pool is full, add salt to the weight of the cabbage heads 2% by weight, marinated for 2 days;

[0035] (3) Shredded from the pond: remove the pickled cabbage head from the pond and shred it for later use;

[0036] (4) Dewatering: Dry the shredded cabbage in step (3) with hot air at 70°C for 2 hours to remove water;

[0037] (5) salting and encapsulation: add salt to the shredded vegetable after dehydration, the weight of adding salt is 4% of the shredded vegetable weight, then pack into the bag and seal;

[0038] (6) Low-temperature fermentation: put the packaged shredded vegetables in a low-temperature environment of 6°C for low-temperature fermentation for 2 months;

[0039] (7) Seasoning packaging: pack the shredded coriander seasoning ...

Embodiment 3

[0041] (1) Cleaning: clean the harvested cabbage heads;

[0042] (2) Add salt to marinate: put the washed cabbage heads in the vegetable pool, spread a layer of salt on the cabbage heads for each layer of cabbage heads until the vegetable pool is full, add salt to the weight of the cabbage heads 3% by weight, marinated for 2 days;

[0043] (3) Shredded from the pond: remove the pickled cabbage head from the pond and shred it for later use;

[0044] (4) Dewatering: Dry the shredded cabbage in step (3) with hot air at 70°C for 2 hours to remove water;

[0045] (5) Add salt and package: add salt to the shredded vegetable after dehydration, the weight of adding salt is 3% of the shredded vegetable weight, then pack into the bag and seal;

[0046] (6) Low-temperature fermentation: put the packaged shredded vegetables in a low-temperature environment of 6°C for low-temperature fermentation for 2 months;

[0047] (7) Seasoning packaging: pack the shredded coriander seasoning marin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com