Long-shelf-life pasteurization yoghourt and preparation method thereof

A pasteurization acid and pasteurization technology, which is applied in the direction of milk preparations, dairy products, applications, etc., can solve the problems of sensory characteristics deterioration, yogurt nutrient destruction, yogurt nutritional value discount, etc., to achieve long shelf life and prevent viscosity Too low, good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

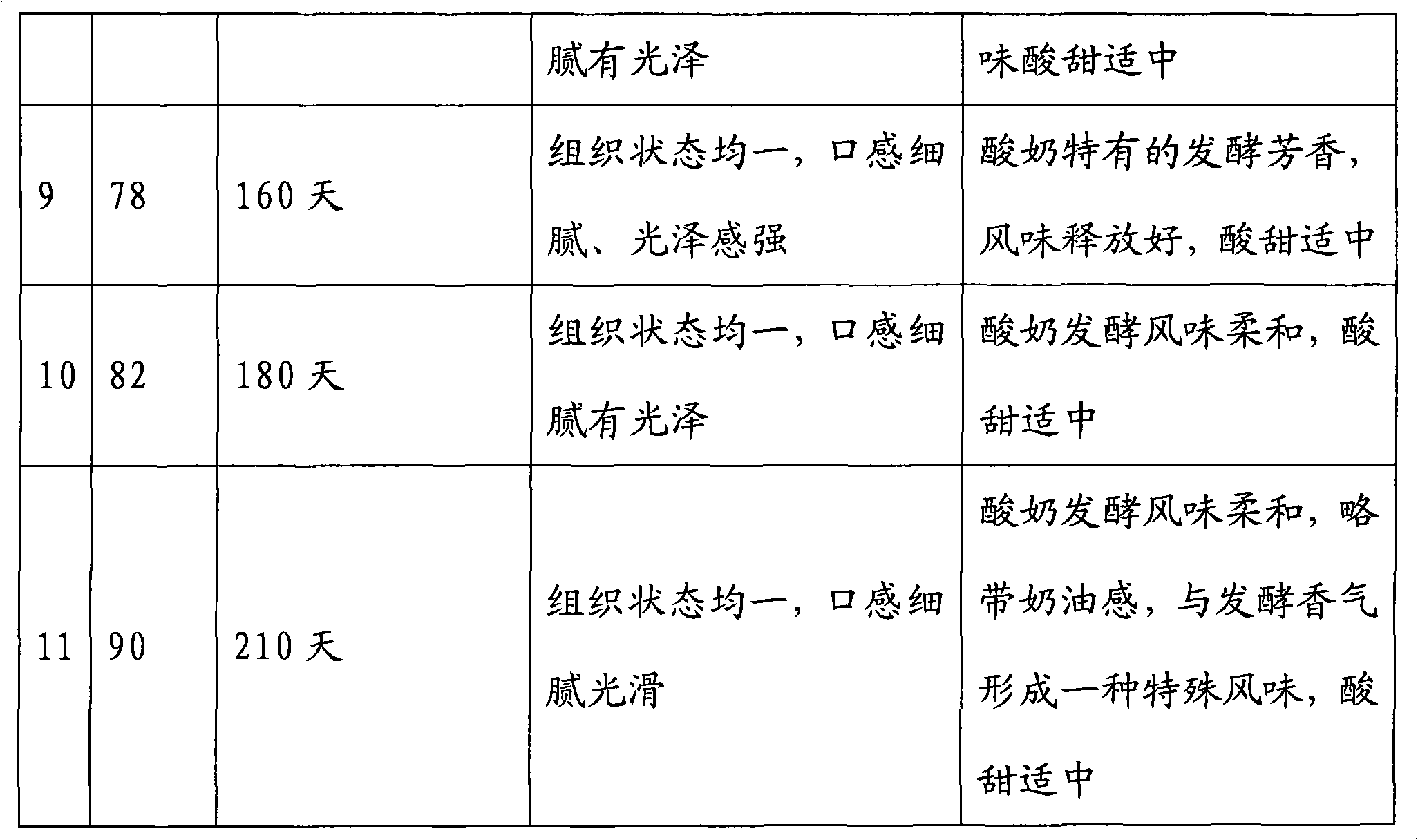

Examples

Embodiment 1

[0034] A kind of preparation method of pasteurized yoghurt with long shelf-life of the present invention, wherein, preparation steps are as follows:

[0035] After the milk is pretreated by a conventional method, mix and add the colloid and sugar at a weight ratio of 1:100 at 50-60° C., wherein the weight ratio of the colloid added amount is: cross-linked starch: sodium alginate: Gelatin:locust bean gum=80:0.8:13:8, the amount of colloid added is 0.1:95 with the weight ratio of milk.

[0036] Then homogenize at 65°C, 25Mpa, pasteurize at 95°C for 5 min, add strains after cooling and ferment at 43°C, stop fermentation at an acidity of 85°C, and sterilize at 75°C for 15s Afterwards, stirring at 43°C until the viscosity range is 4000cP and directly filled to obtain the product of the present invention.

Embodiment 2

[0038] A kind of preparation method of pasteurized yoghurt with long shelf-life of the present invention, wherein, preparation steps are as follows:

[0039] After the milk is pretreated by a conventional method, the weight ratio of the colloid and sugar is mixed at 50°C and the weight ratio of the colloid and sugar is 1:50, wherein the weight ratio of the colloid addition amount is: cross-linked starch: sodium alginate: gelatin: Pectin=80:0.8:5:10, the weight ratio of colloid to raw milk is 0.1:99.9.

[0040] Then homogenize at 60°C, 25Mpa, and pasteurize at 90°C for 10 minutes, add strains after cooling and ferment at 40°C, stop fermentation at an acidity of 65°C, and sterilize at 75°C for 15s , stirred at 43°C until the viscosity range is 6000cP and directly filled to obtain the product of the present invention.

Embodiment 3

[0042] A kind of preparation method of pasteurized yoghurt with long shelf-life of the present invention, wherein, preparation steps are as follows:

[0043] After the milk is pretreated by conventional methods, mix and add the colloid and sugar at a weight ratio of 1:10 at 55° C., wherein the weight ratio of the colloid added amount is: esterified starch: sodium alginate: gelatin: Agar=80:0.8:5:20, the amount of colloid added is 5:99.9 with the weight ratio of raw milk.

[0044] Then homogenize at 60-65°C, 21Mpa, pasteurize at 92°C for 8 minutes, add strains after cooling and ferment at 42°C, stop fermentation at an acidity of 70°C, 75°C, 15s After sterilization, it is stirred at 43° C. until the viscosity range is 2000 cP and directly filled to obtain the product of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com