Poultry egg detection method and device in automatic grading assembly line of poultry eggs

An automatic grading and detection device technology, applied in the poultry industry, testing food, testing eggs, etc., can solve the problems of egg weight, light, light transmission and crack detection without forming a complete set, scattered cleaning and testing equipment, etc. The effect of smooth transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

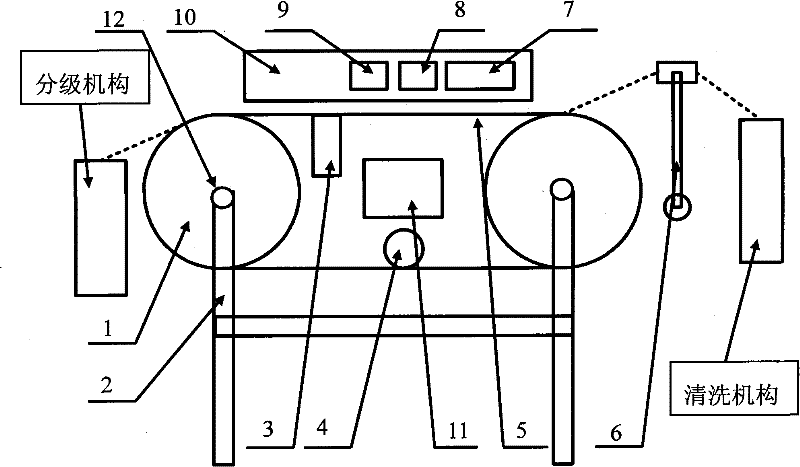

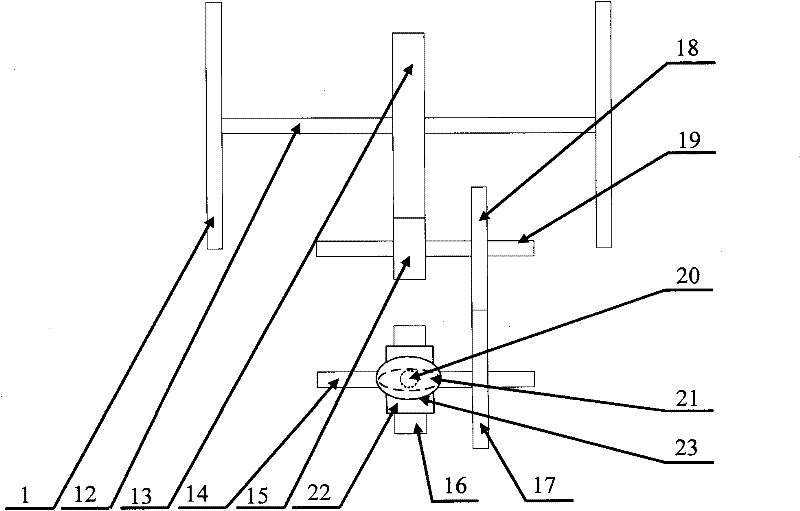

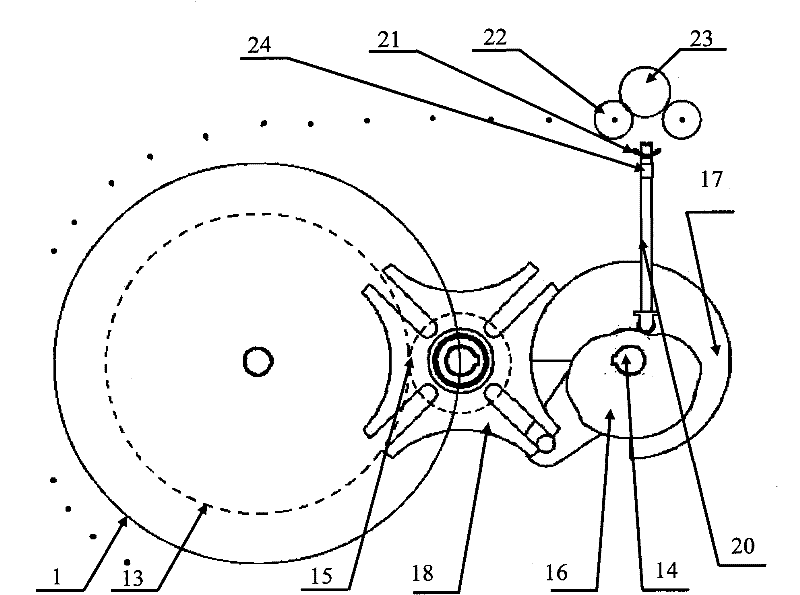

[0014] Such as figure 1 As shown, two large sprockets 1 are fixedly installed at both ends of the frame 2 of the detection device of the present invention, the sprocket shaft 12 is connected between the two large sprockets 1, and the transmission chain 5 is located on the two large sprockets 1 for intermittent motion transmission . A chain tensioner 4 is arranged on the transmission chain 5 . One side of the large sprocket 1 places a parallel movement mechanism 6, and the poultry eggs cleaned up in the cleaning mechanism are moved from the cleaning mechanism 6 to the transmission chain 5 by the parallel movement mechanism 6, and are intermittently moved under the drive of the large sprocket 1. Between the two large sprockets 1 and above the transmission chain 5, there is an upper cover plate 10, on which three detection devices for crack detection 7, light transmission detection equipment 8, and light detection equipment 9 are sequentially fixed. , this structure makes the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com