Printed circuit board

A technology of printed circuit board and power supply, which is applied in the direction of printed circuit, printed circuit, printed circuit manufacturing, etc., can solve the problems of increasing cost, achieve the effect of reducing input impedance, reducing cost and increasing capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

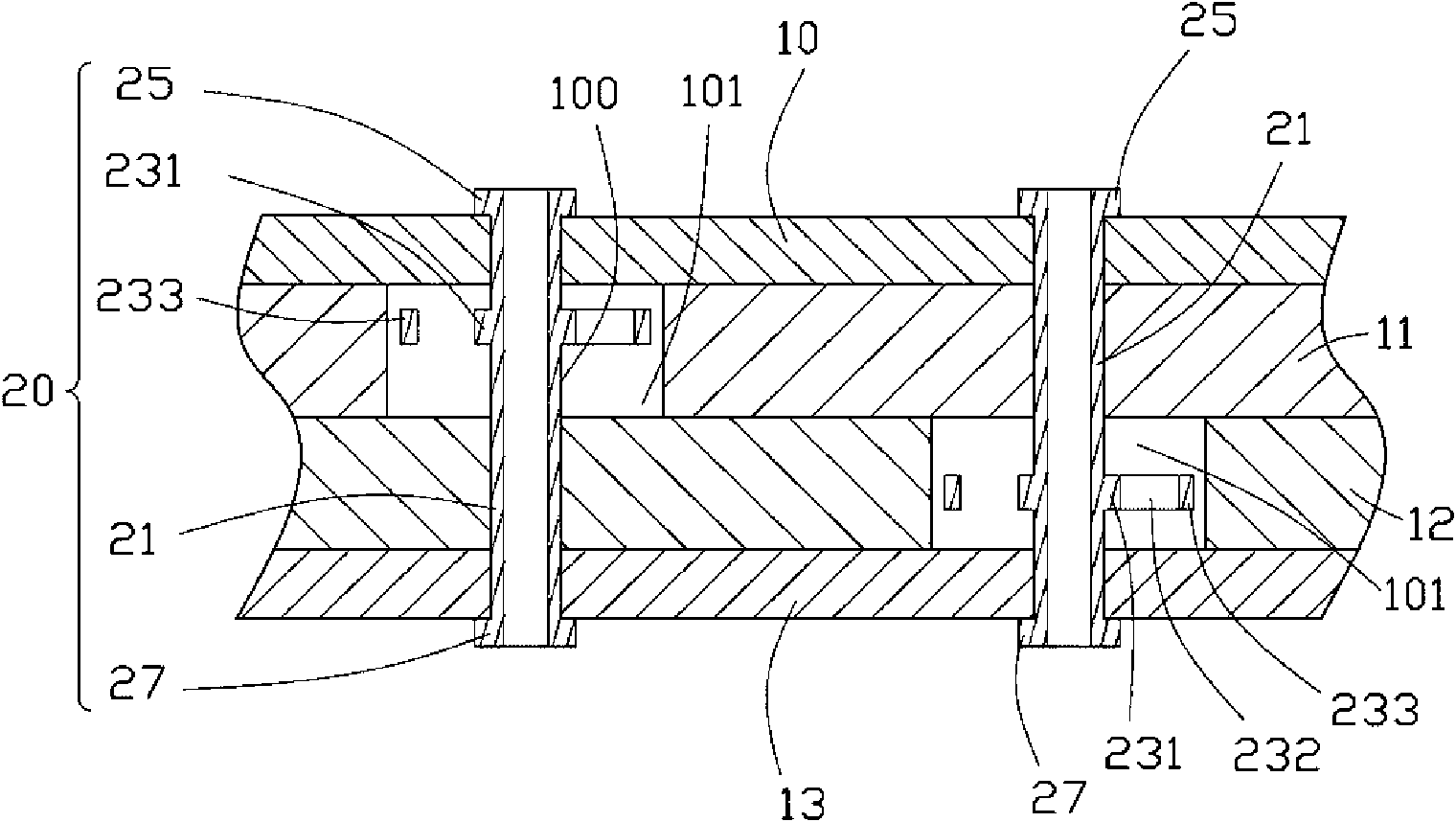

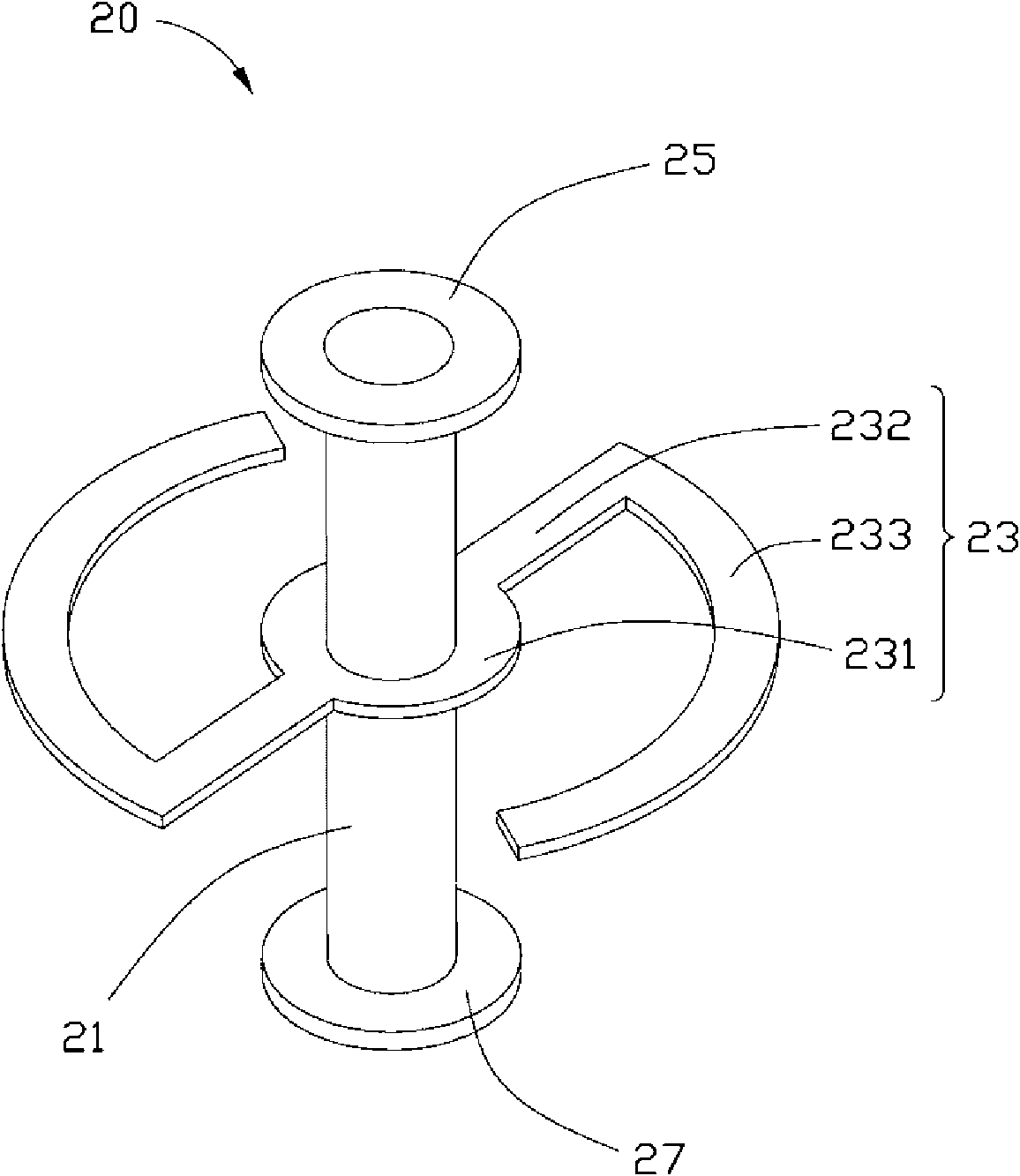

[0011] Please refer to figure 1 and figure 2 A preferred embodiment of the printed circuit board of the present invention includes a first signal layer 10 , a power layer 11 , a ground layer 12 and a second signal layer 13 sequentially placed from top to bottom. A plurality of grounding vias and a plurality of power supply vias 100 are longitudinally disposed on the printed circuit board. The part of the ground via located on the power layer 11 and the part of the power via located on the ground layer 12 are enlarged to form an isolation space 101 . Each ground via hole and power via hole 100 forms a conductor 20 . Each conductor 20 includes a cylindrical main body 21 located in the via hole 100 , an extension 23 disposed around the main body 21 , and pads 25 and 27 disposed at two ends of the main body 21 . Wherein, the pad 25 is located on the first signal layer 10 , the pad 27 is located on the second signal layer 13 , and the extension 23 is located in the isolation sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com