Rotating speed tracking and sampling and spectrum number curing and analyzing method of variable speed mechanical fault diagnosis

A technology of mechanical failure and rotational speed signal, which is applied in the direction of speed/acceleration/shock measurement, linear/angular velocity measurement, measuring device, etc. It can solve the problems that the signal sample does not meet the periodicity, cannot diagnose the limitation of the fault, and determine the frequency spectrum. Achieve the effect of facilitating computer automatic diagnosis, improving time coverage and preventing blind spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Below in conjunction with embodiment do further explanation.

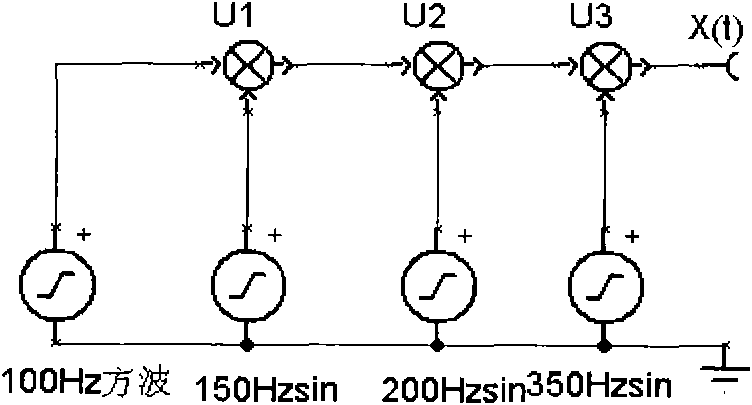

[0054] For example, assume that the rotational speed frequency of a certain axle is fn, the multiplication factor is X=200, the speed tracking sampling sample length is N=2048, and the transmission ratio η=76 / 17=4.4706 of the adjacent shaft pinion to the axle, according to Table 4 From Equation 8, the fault-curing characteristic clef of the pinion is:

[0055] PH8=ηN / X=76 / 17*2048 / 200=45.77

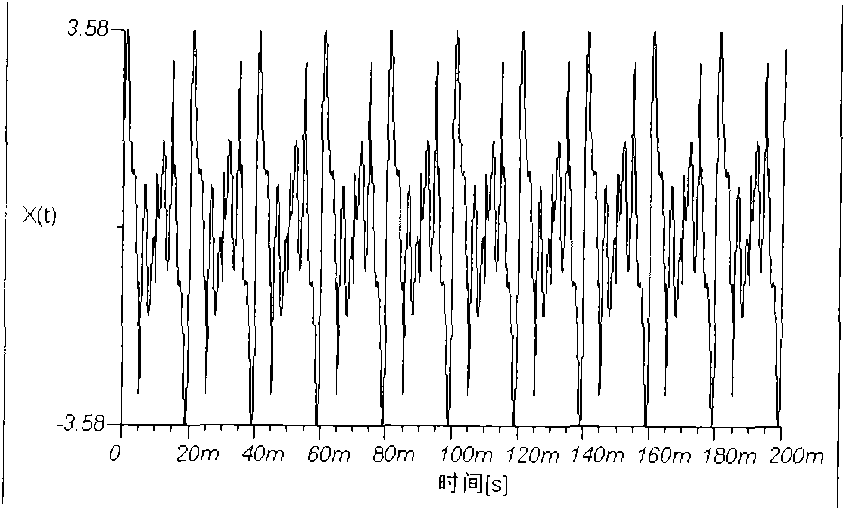

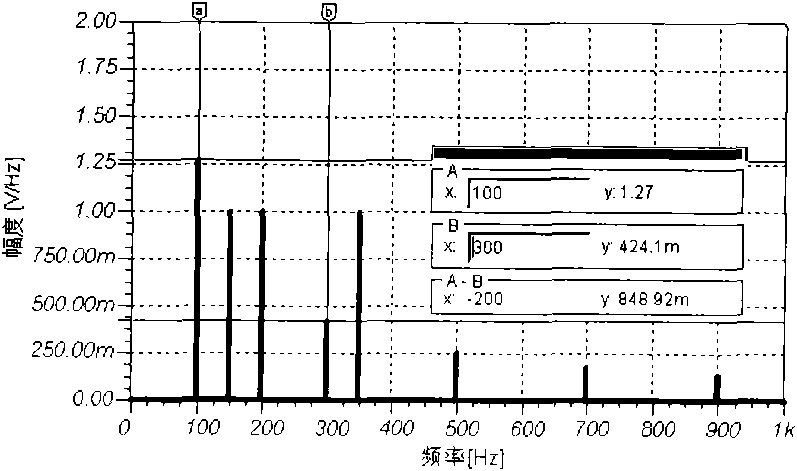

[0056] Figure 4 When the average speed of the axle is 242r / min (the average speed of the pinion is 1082r / min), the fault waveform of the speed tracking sampling, the FFT analysis spectrum and the "theoretical abstract spectrum" of the pinion bearing and pinion calculated according to Table 4. Among them, the actual clef of the pinion fault is 45.74, which is in line with the theoretical clef;

[0057] Figure 5 It is the fault waveform, FFT analysis spectrum and the "theoretical abstract spectrum" of the pinion bear...

Embodiment 2

[0061] Speed tracking sampling for fault diagnosis of variable speed machinery and speed signal sharing technology for clef solidification analysis method.

[0062] In the field of rail transit, vehicles are organized into trains. But not only the diameters of the wheels of different vehicles are different, but also the diameters of the two wheels of one axle of the same vehicle are different from the two wheels of other axles. Only the diameters of the two wheels of the same axle are controlled to be negligible within the margin of error. Due to the limitation of the cost and the allowable installation position, it is almost impossible to install the rotational speed sensor 1 and the frequency multiplier 2 for each axle to obtain the Xfn signal of the axle. Therefore, it is expected to obtain Yfn from the rotational speed sensor 1 of one axle, and process it into an Xfn signal through the frequency multiplication circuit 2 for sharing by the whole vehicle.

[0063] To thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com