Continuous vertical hot evaporation metal film coating method

A metal coating and thermal evaporation technology, which is applied in vacuum evaporation coating, metal material coating process, sputtering coating, etc., can solve the problems of metal wire grid polarization failure and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

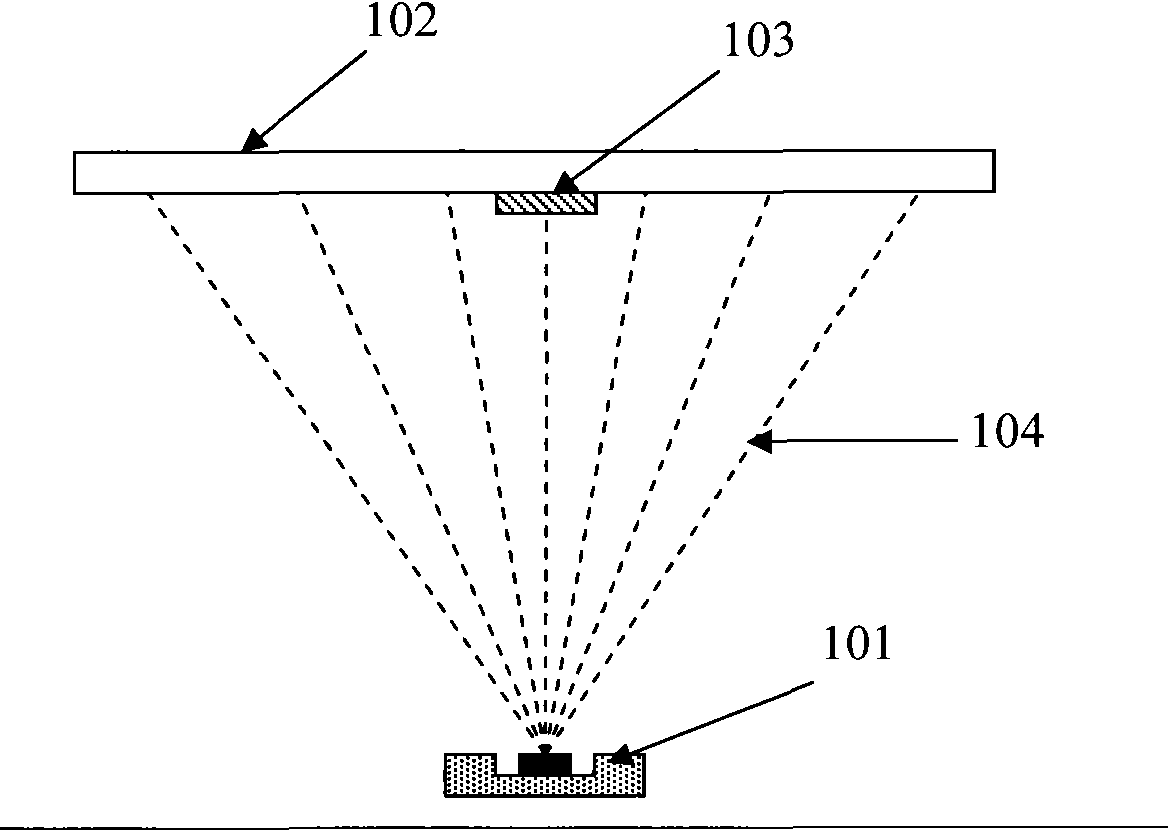

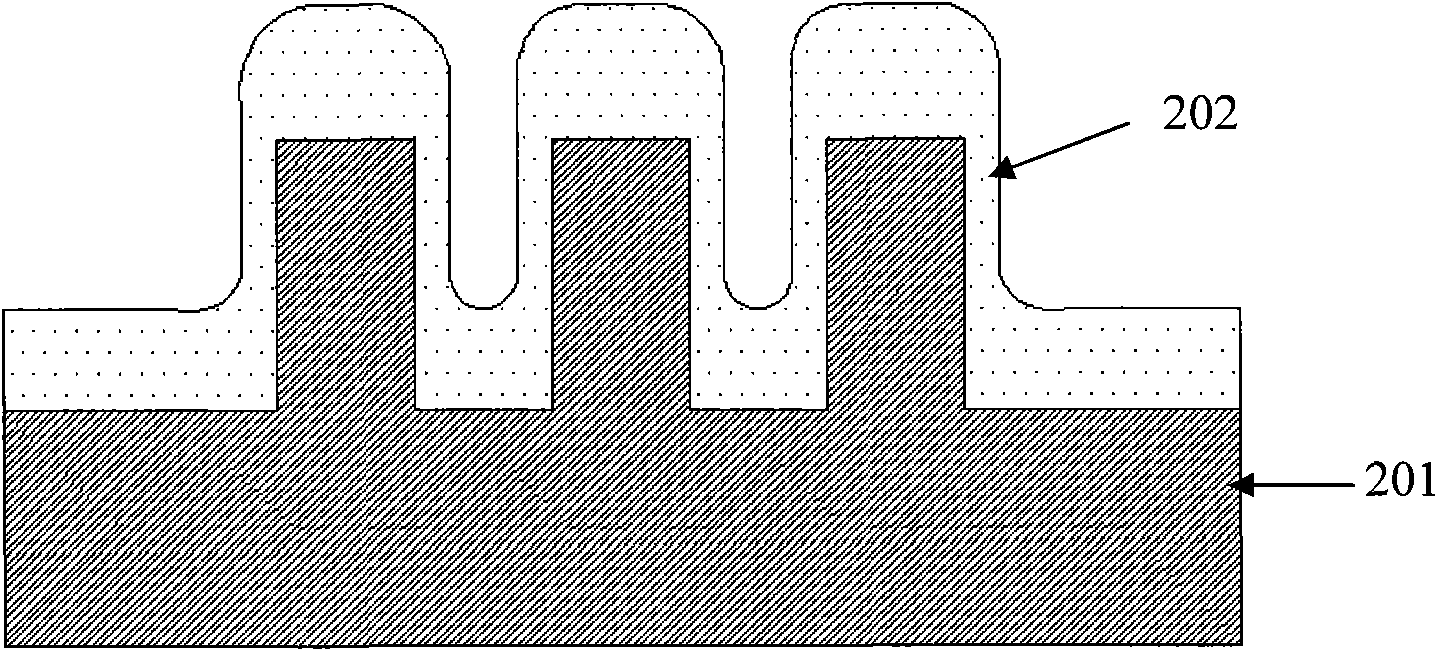

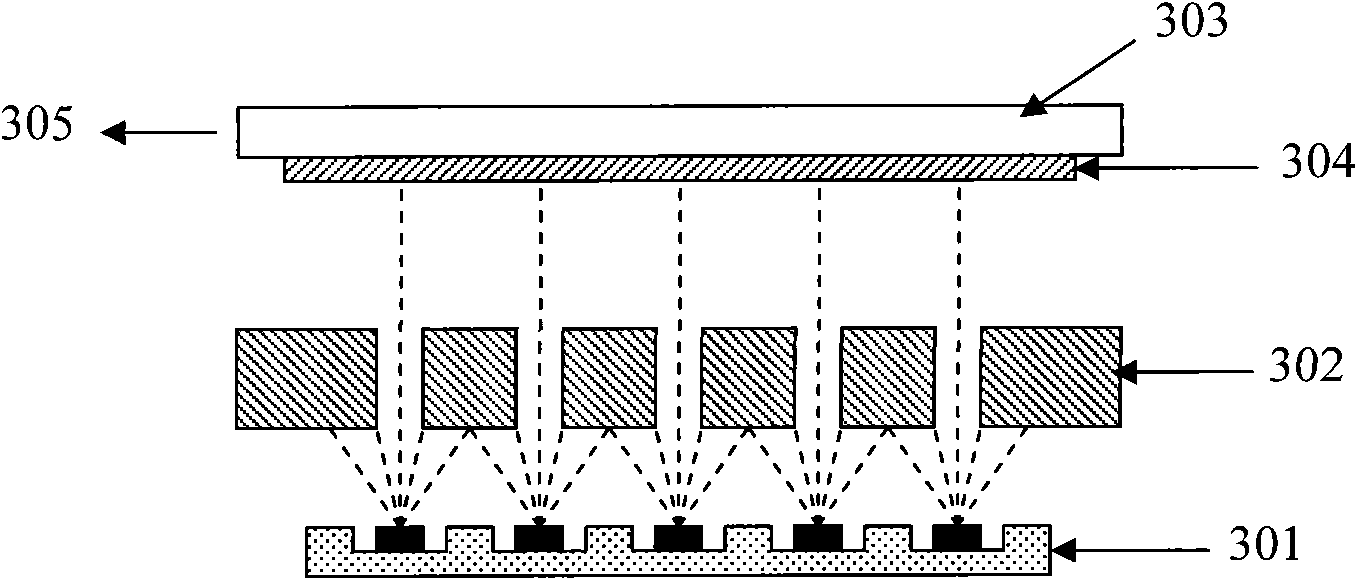

[0019] In order to avoid the phenomenon that the upper surface of the relief structure and the metal film at the bottom of the opening are connected to each other during the metal coating process in the prior art, which affects the filtering of the polarization component of the incident light, a continuous vertical thermal evaporation method is proposed. Metal coating method.

[0020] From the perspective of the process of traditional coating methods: conventional point evaporation sources are used to vapor-deposit metal films from bottom to top on small-area sample substrates, which can obtain deposited film thicknesses with better uniformity and directionality. However, for large-area samples, the farther the sample surface is from the central area vertically above the thermal evaporation source, the worse the thickness uniformity and deposition directionality of the metal film become. The reason is that the divergent jet direction of metal molecules is very easy to deposit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com