Dust inhibitor and preparation method thereof

An inhibitor and dust technology, applied in chemical instruments and methods, other chemical processes, etc., can solve problems affecting equipment life, dust explosion and fire, health crisis, etc., and achieve the effect of reducing costs, protecting the environment, and improving economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

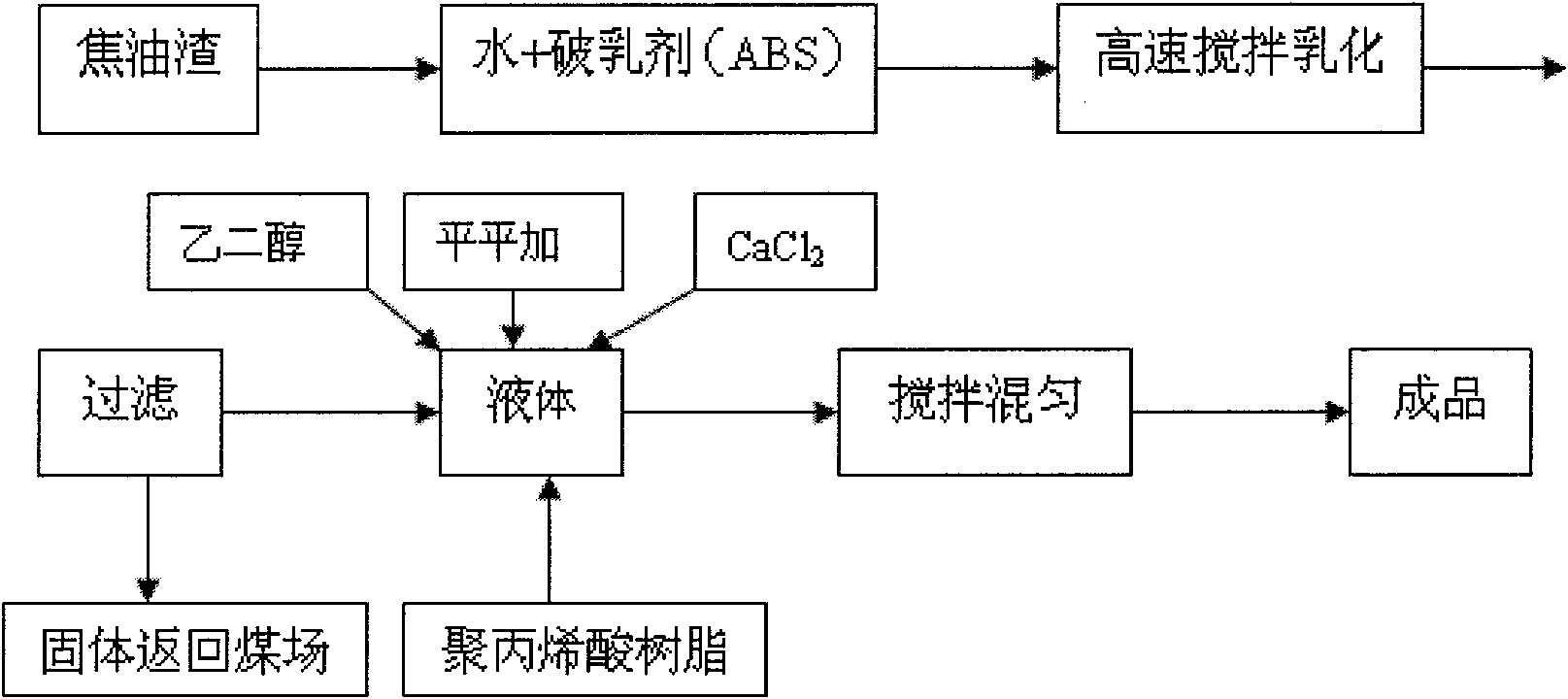

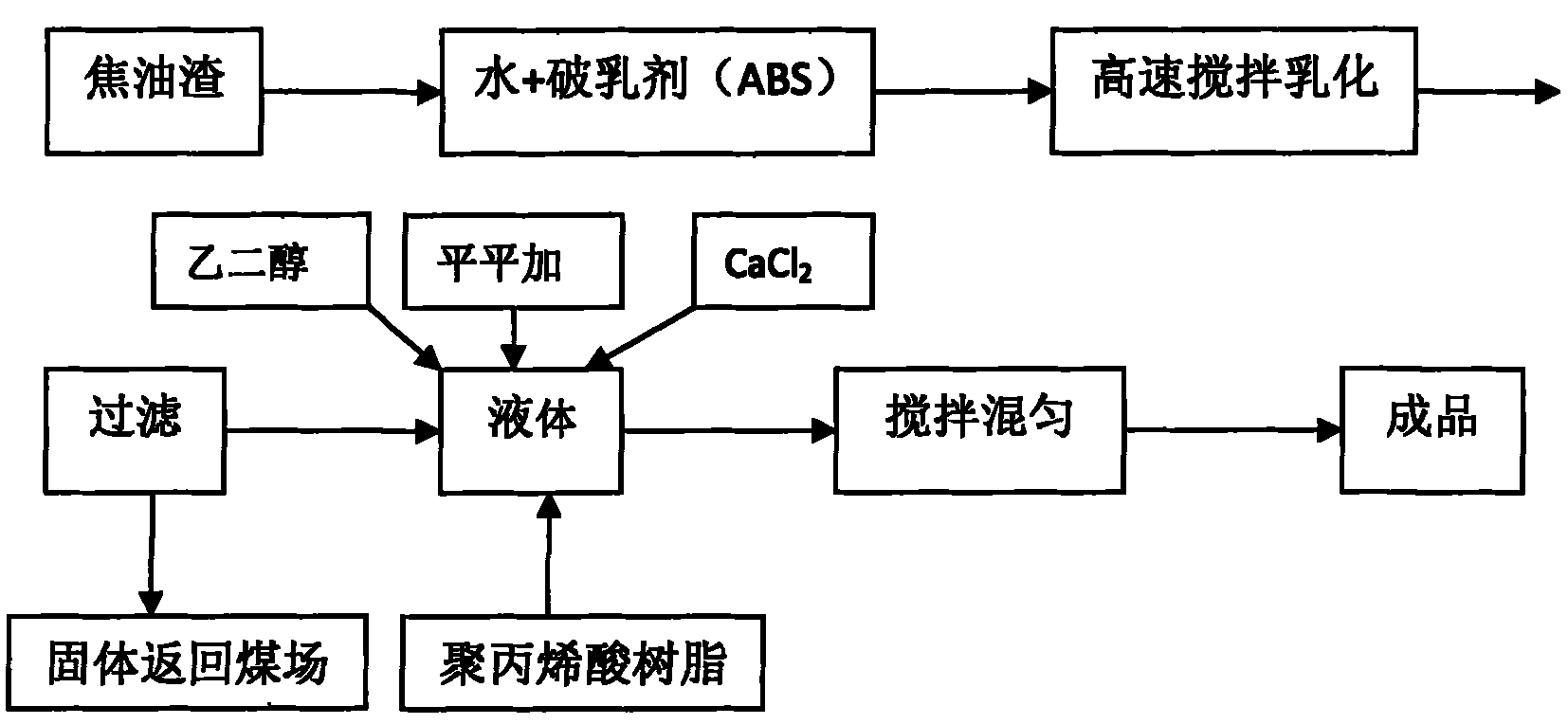

Method used

Image

Examples

Embodiment 1

[0038] Take 437.5g of reverse osmosis concentrated water, add 22.5g of demulsifier sodium dodecylbenzene sulfonate (ABS), mix well, add 300g of tar emulsion, emulsify it on the emulsifier at 180r / s, emulsify for 30 minutes, filter , Add 10g of ethylene glycol to the remaining liquid, add 100g of polyacrylic resin, stir evenly, add 5g of surfactant, add 125g of calcium chloride, and stir evenly.

Embodiment 2

[0040] Take 510g of reverse osmosis concentrated water, add 25g of demulsifier sodium dodecylbenzene sulfonate (ABS), mix well, add 240g of tar emulsion, emulsify on the emulsifier at speed: 190r / s, emulsify for 30 minutes, filter, Add 15 g of ethylene glycol to the remaining liquid, add 90 g of polyacrylic resin, and stir evenly, add 5 g of surfactant, add 115 g of calcium chloride, and stir evenly.

Embodiment 3

[0042] Take 490.5g of reverse osmosis concentrated water, add 20g of demulsifier sodium dodecylbenzene sulfonate (ABS), mix well, add 260g of tar emulsion, on the emulsifier at a speed of 180r / s, emulsify for 35 minutes, filter, Add 7.5 g of ethylene glycol to the remaining liquid, add 110 g of polyacrylic resin, and stir evenly, add 7 g of surfactant, add 105 g of calcium chloride, and stir evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com