Expansion and shrinkage seamless recoiling machine of radial oil cylinders of twenty-high roll steel plate cold rolling mill

A twenty-high, cold rolling mill technology, applied in the field of metallurgical equipment, can solve the problems affecting the service life, wear and failure of the coiler, and achieve flexible and reliable expansion and contraction movements, good processing technology, and easy to ensure accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

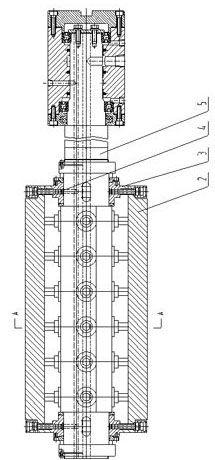

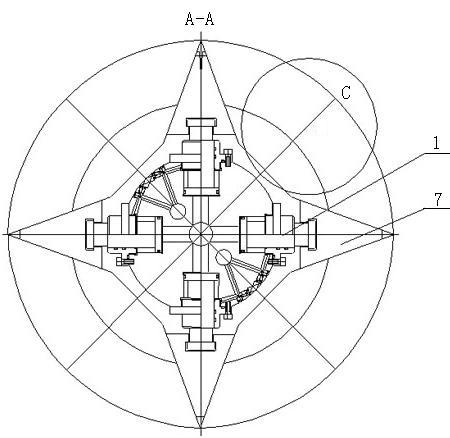

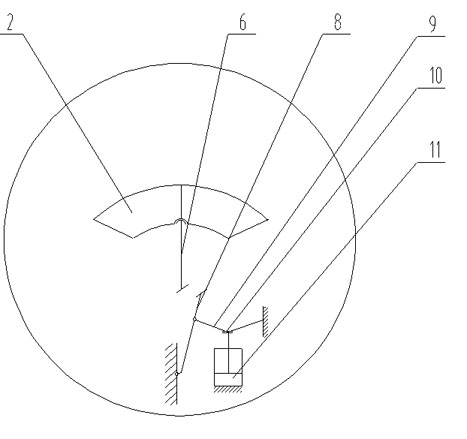

[0013] Such as figure 1 , figure 2 and image 3 As shown, the four radial oil cylinders 1 form 90 degrees to each other and are radially distributed according to the rotary spindle 5 in the four-lobe block 2, and the four-lobe booster piston 4 of each radial oil cylinder 1 is radially connected to the telescopic inclined block 7, and the telescopic inclined block The triangular inclined surface of 7 is connected with the four-petal block 2 at intervals. When the four radial oil cylinders 1 respectively enter the pressure oil, the four-petal booster piston 4 moves telescopically, and the four-petal booster piston 4 drives the connected telescopic inclined block 7 to also expand and contract. Movement, and then the four-petal block 2 is pushed by the four telescopic inclined blocks 7 to complete the expansion and retraction of the four-petal block 2. It can bear a large tangential direction. When the four-petal block 2 is in the expanded position, the pulling rod cylinder 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com