Secondary vibration feedback control device for Coriolis mass flow meter

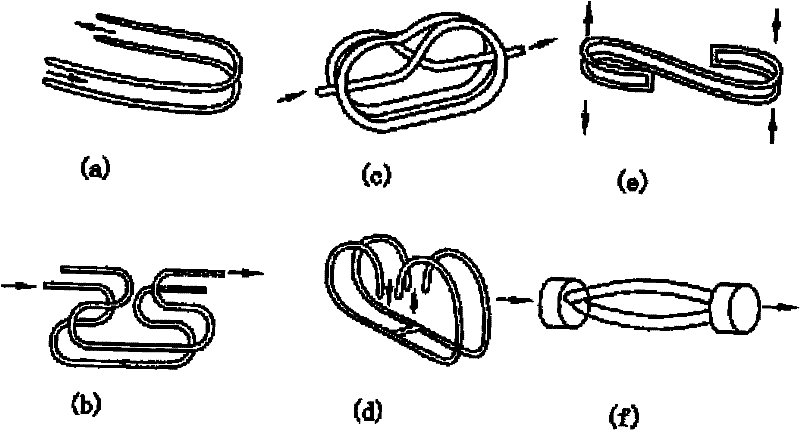

A mass flow meter and feedback control technology, applied in the direction of mass flow measurement device, direct mass flow meter, computer control, etc., can solve the problems of restricted range, weak linear relationship, measurement influence of Coriolis mass flow meter 11, etc. range, the effect of reducing coupling vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings.

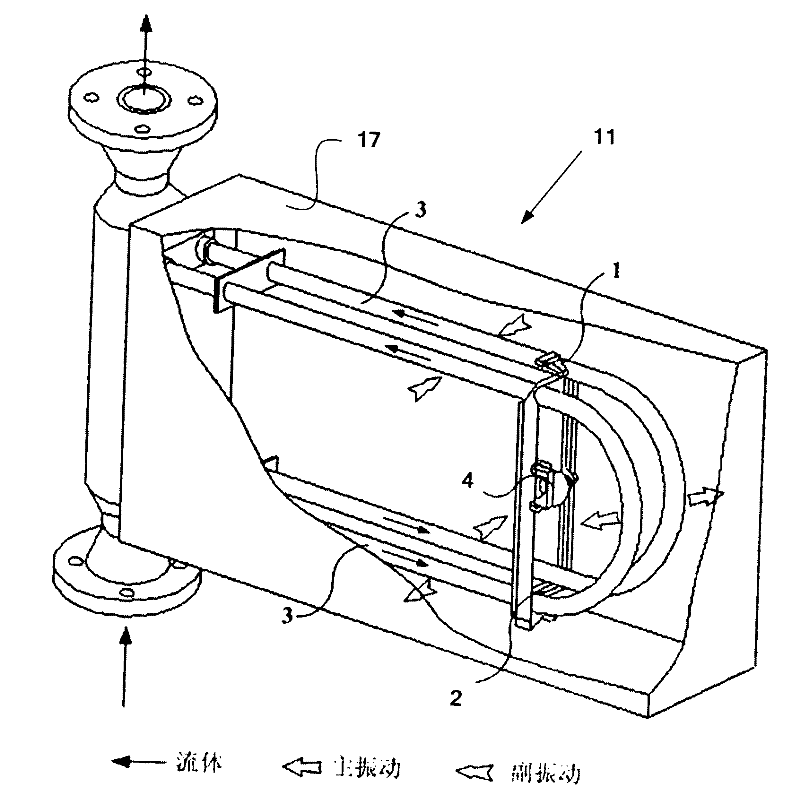

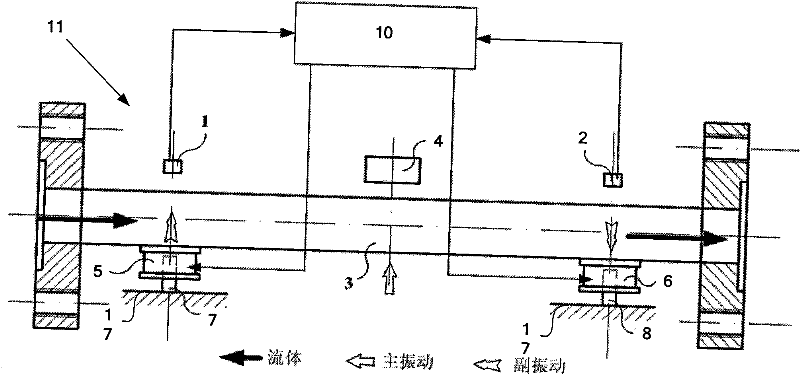

[0040] A secondary vibration feedback control device for a Coriolis mass flowmeter of the present invention includes a Coriolis torsion control circuit 10 and a first coil 5, a second coil 6, and a cylindrical magnetic coil installed on a Coriolis mass flowmeter 11. Steel A7, column magnetic steel B8. The invention is suitable for straight tube Coriolis mass flowmeters and curved tube Coriolis mass flowmeters.

[0041] Such as image 3Shown is an installation example of the auxiliary vibration feedback control device of the present invention on a single straight tube Coriolis mass flowmeter. It can be seen that the first speed sensor 1 and the second speed sensor 2 are installed at the two ends of the measuring tube 3, and the vibrator 4 Located in the middle of the measuring tube 3, the first coil 5 and the second coil 6 are respectively fixed on the side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com