Liquid crystal display panel and manufacture method thereof

A technology for liquid crystal display panels and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, optics, instruments, etc., and can solve problems that affect the display effect of LCD products, reduce production efficiency, and increase production costs, so as to reduce labor costs and maintenance time , Improve yield rate and reduce production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

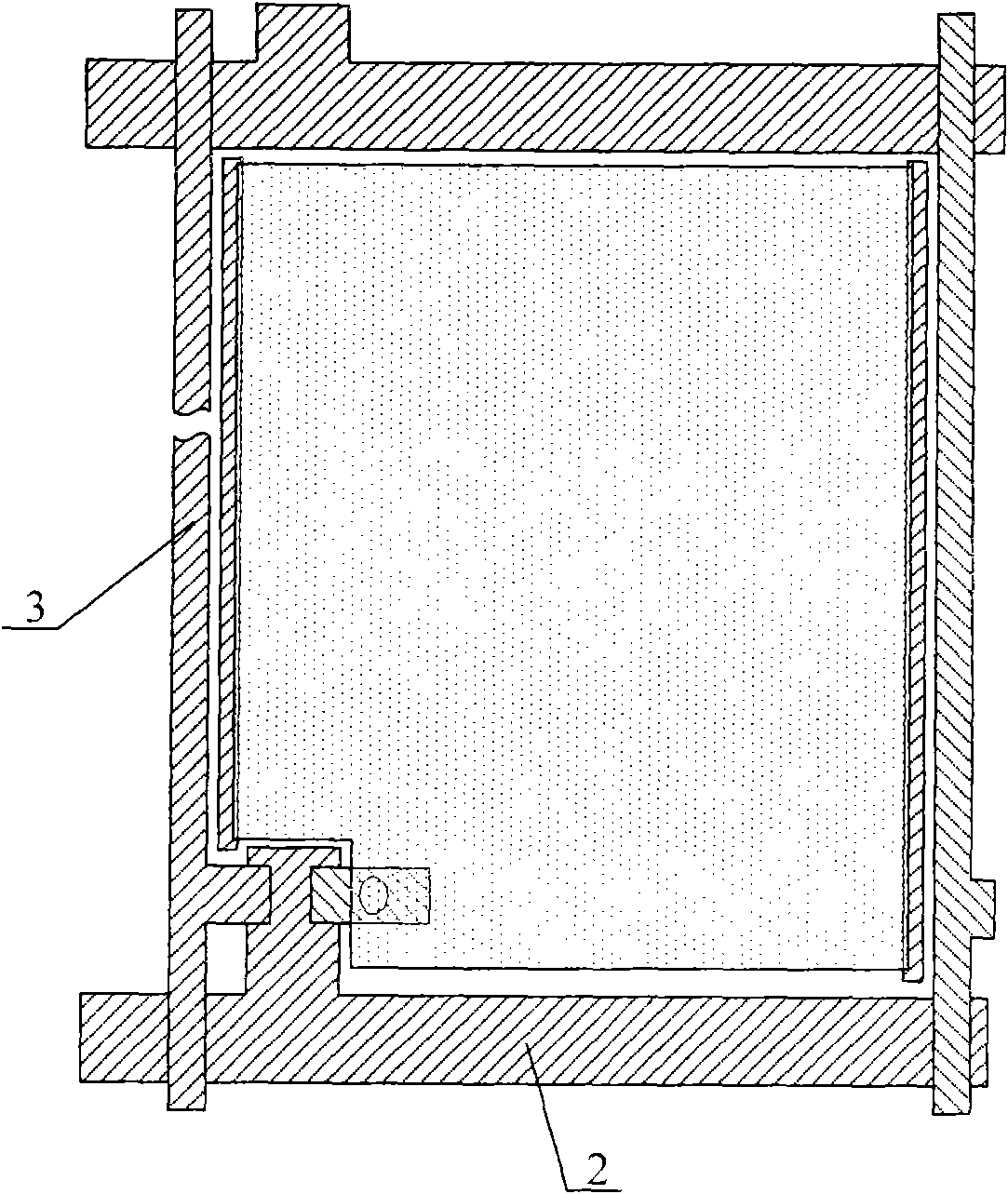

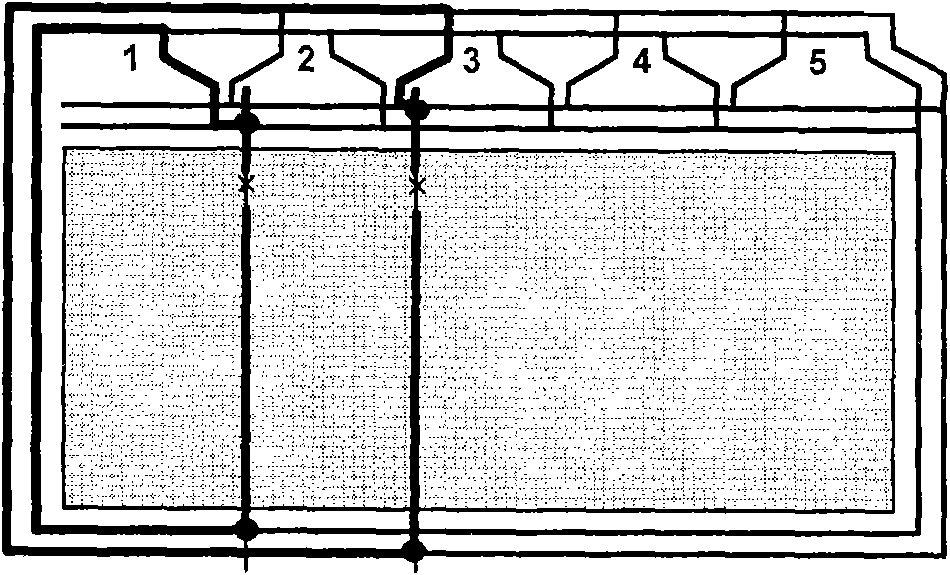

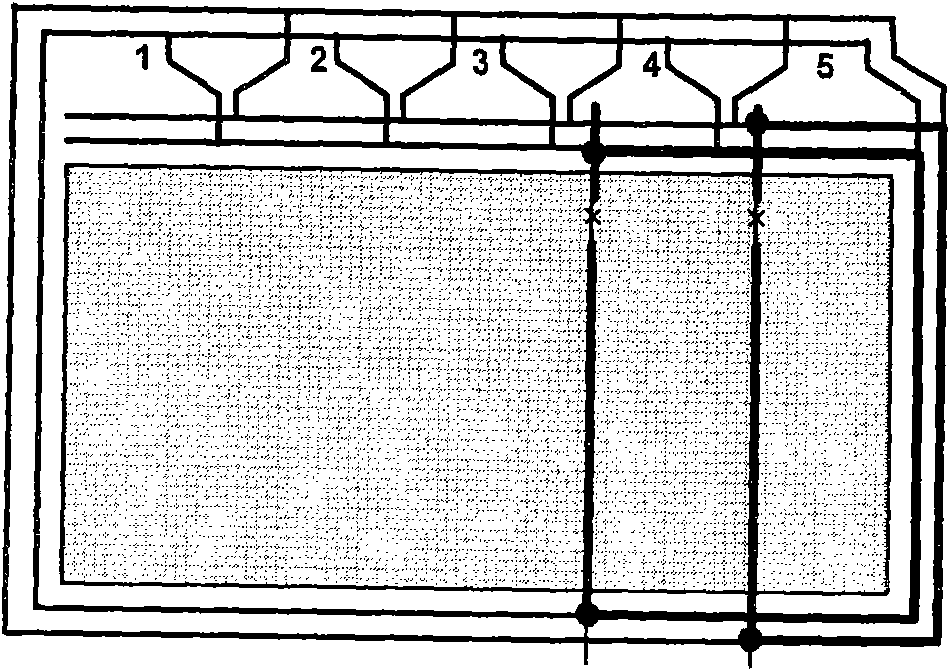

[0035] Figure 6 It is a schematic diagram of the pixel structure of the liquid crystal display panel of the present invention, Figure 7 for Figure 6 Schematic diagram of the cross-section in the direction of A1-A1, Figure 8 for Figure 6 Schematic cross-sectional view of B1-B1 direction. Such as Figure 6 ~ Figure 8 As shown, the liquid crystal display panel provided by this embodiment includes gate lines 2 and data scanning lines 3 formed on the substrate 1, and pixel electrodes and thin film transistors are formed in the pixel area defined by the gate lines 2 and data scanning lines 3, and are perpendicular to each other. The gate line 2 and the data scanning line 3 define the pixel area, the thin film transistor and the pixel electrode are formed in the pixel area, the gate line 2 is used to provide the tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com