Detection method of mercury content in burning coal

A detection method and content technology are applied in the detection field of mercury content in coal combustion, which can solve the problems of high cost, inability to detect, and high requirements for equipment and operators, and achieve the effects of low cost and convenient detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

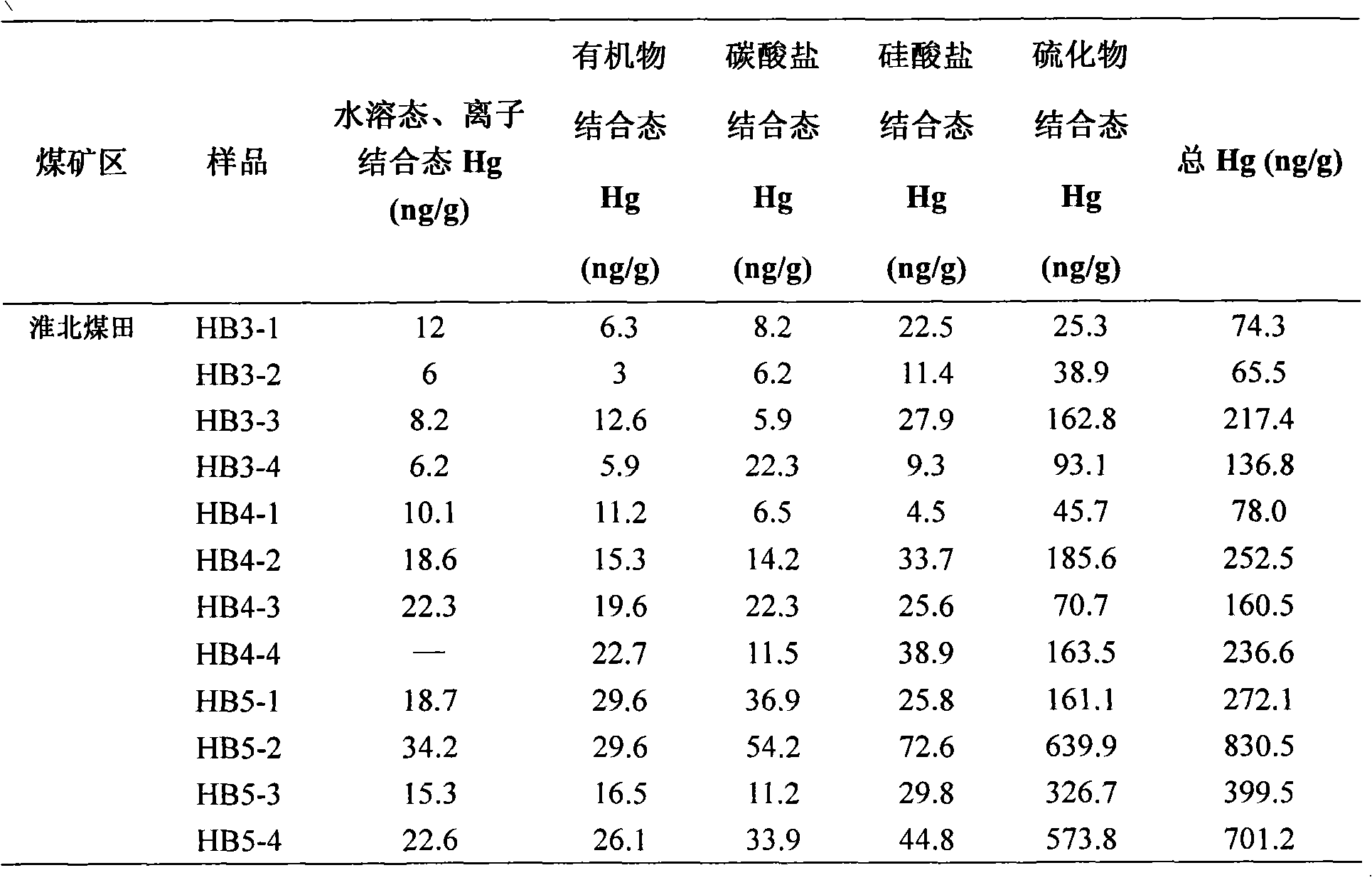

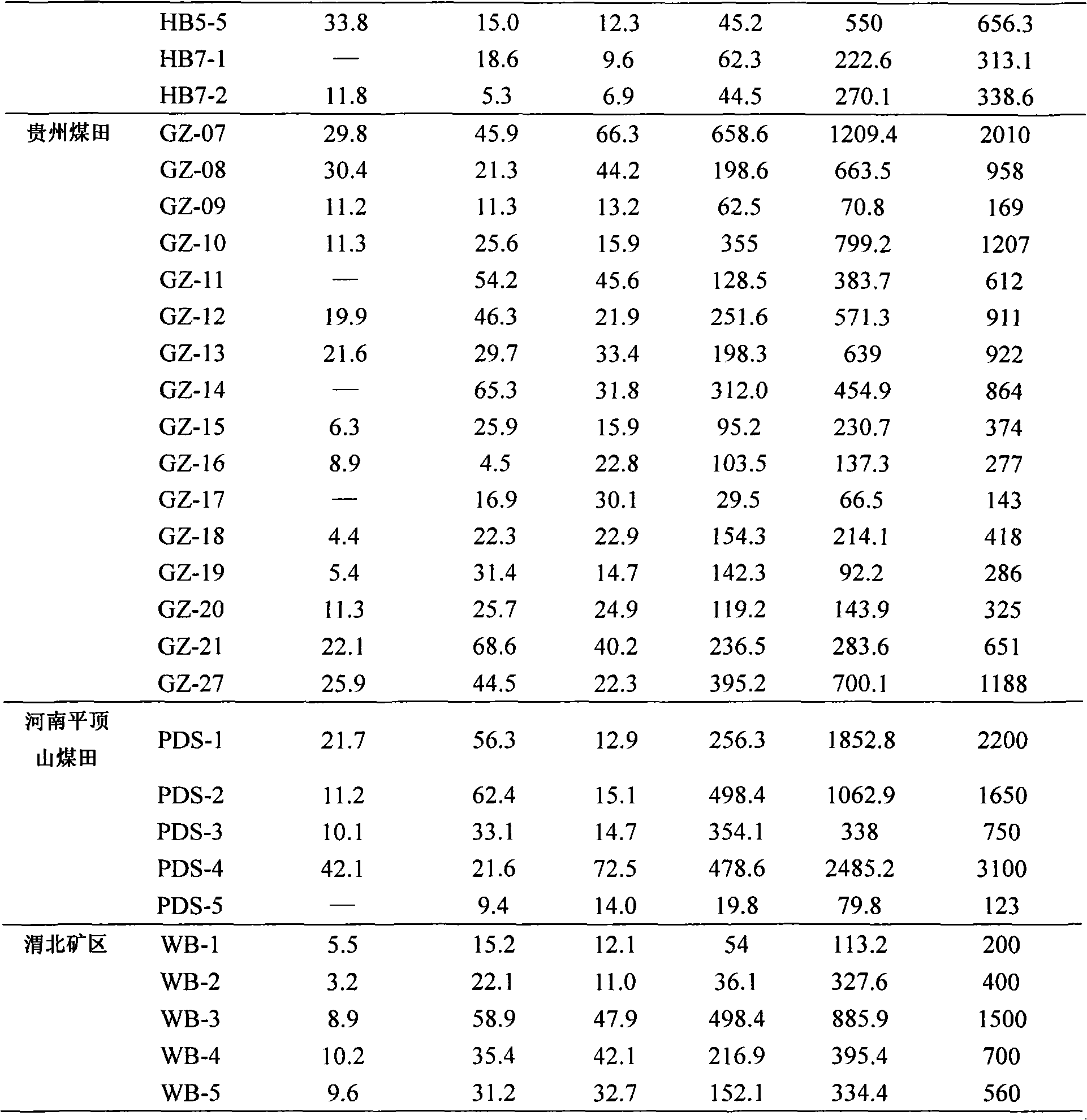

[0027] In this embodiment, a batch of raw coals numbered HB3-1 from the Huaibei coalfield were obtained. In order to provide guiding parameters for the demercury treatment of its coal-fired flue gas, the method of the present invention was used to detect the mercury content in the raw coal numbered HB3-1 of the Huaibei coalfield. Proceed as follows:

[0028] 1) Pretreatment and sample preparation: use a grinder to grind the raw coal to 200 meshes, turn on the thermostat and set it at 110°C for 2 hours, then put the raw coal into the thermostat and heat at 110°C for 12 hours to obtain a raw coal sample.

[0029] 2) Preparation of reagents: A reagent: 1mol / L sodium acetate (C 2 h 5 COONa); B reagent: deionized water; C reagent: specific gravity is 1.47g / cm 3 Chloroform (CHCl 3 ) solution; D reagent: 15.3mol / L of HNO 3 , 12mol / L of HCL and 10mol / L of HF in a volume ratio of 3:1:1 mixture; E reagent: 15% HCl; F reagent: specific gravity of 2.89g / cm 3 Bromoform (CHBr 3 ) solu...

Embodiment 2

[0043] In this embodiment, a batch of raw coals numbered GZ-07 from Guizhou coalfields were obtained. In order to provide guiding parameters for the demercury treatment of coal-fired flue gas, the method of the present invention was used to detect the mercury content in raw coals numbered GZ-07 in Guizhou coalfields. Proceed as follows:

[0044] 1) Pretreatment and sample preparation: use a grinder to grind the raw coal to 150 mesh, turn on the thermostat and set it at 100°C for 2 hours, then put the raw coal into the thermostat and heat it at 100°C for 18 hours to obtain a raw coal sample.

[0045] 2) Preparation of reagents: A reagent: 1mol / L sodium acetate (C 2 h 5 COONa); B reagent: deionized water; C reagent: specific gravity is 1.55g / cm 3 Chloroform (CHCl 3 ) solution; D reagent: the HNO3 of 15.3mol / L, the HCL of 12mol / L and the HF of 10mol / L by volume ratio 3: 1: 1 mixed solution; E reagent: the HCl of 13%; F reagent: specific gravity is 2.76 g / cm 3 Bromoform (CHBr...

Embodiment 3

[0059] In this embodiment, a batch of raw coals numbered PDS-2 from the Pingdingshan Coalfield in Henan Province were obtained. In order to provide guidance parameters for the mercury removal treatment of its coal-fired flue gas, the method of the present invention was used to detect the mercury content in the PDS-2 numbered raw coals of the Pingdingshan Coalfield in Henan Province. ,Specific steps are as follows:

[0060] 1) Pretreatment and sample preparation: use a grinder to grind the raw coal to 50 meshes, turn on the thermostat and set it at 95°C for 2 hours, then put the raw coal into the thermostat and heat at 95°C for 24 hours to prepare raw coal samples.

[0061] 2) Preparation of reagents: A reagent: 1mol / L sodium acetate (C 2 h 5 COONa); B reagent: deionized water; C reagent: specific gravity is 1.21g / cm 3 Chloroform (CHCl 3 ) solution; D reagent: 15.3mol / L of HNO 3 , 12mol / L of HCL and 10mol / L of HF in a volume ratio of 3:1:1 mixture; E reagent: 10% HCl; F rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com