Improvement of driving mechanism of crankless engine

A technology driven by an engine without a crankshaft. It is applied in the direction of machines/engines, mechanical equipment, transmissions, etc. It can solve the problems that the gear transmission is difficult to achieve accurate timing, and achieve good rigidity, less processing and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

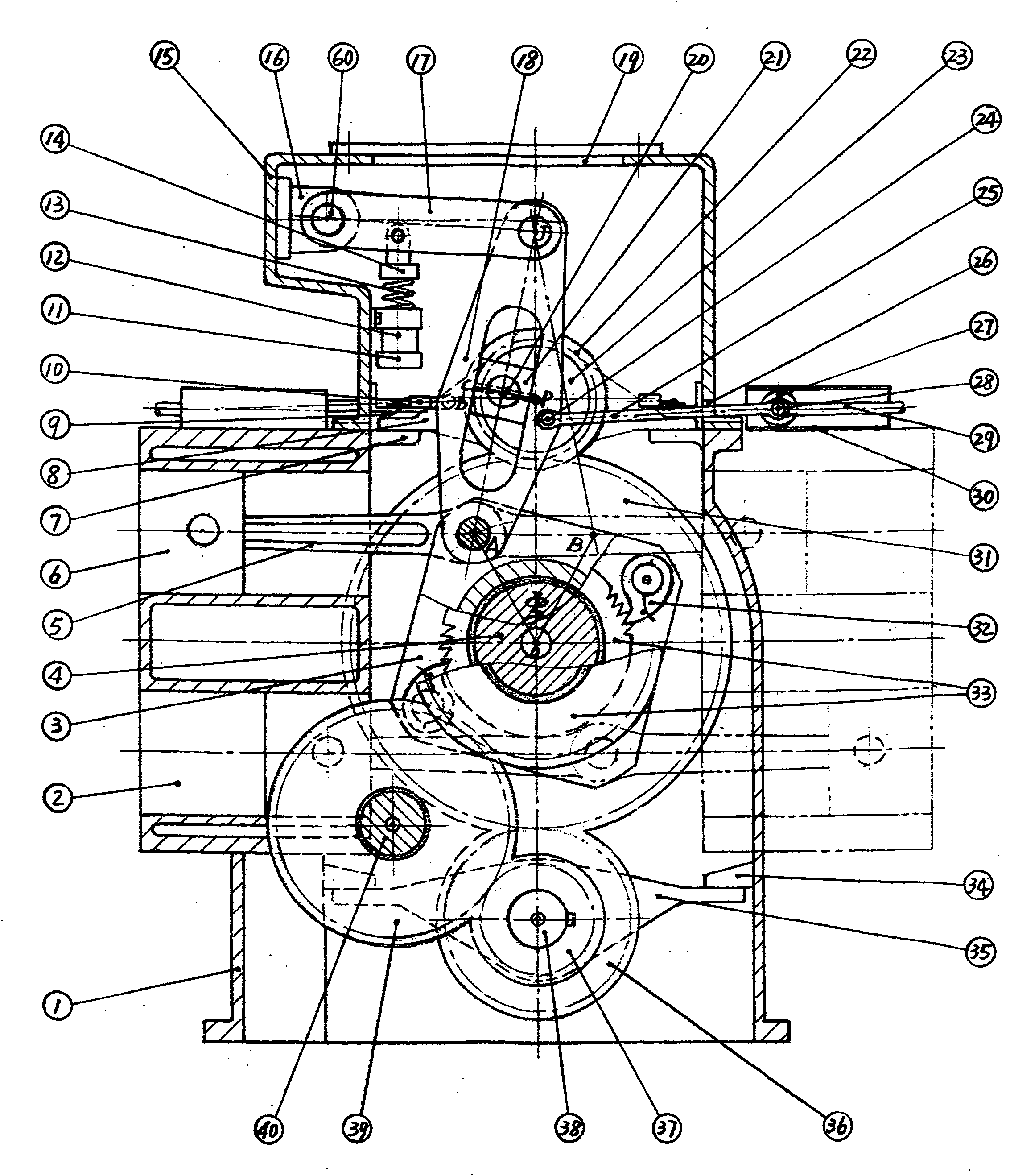

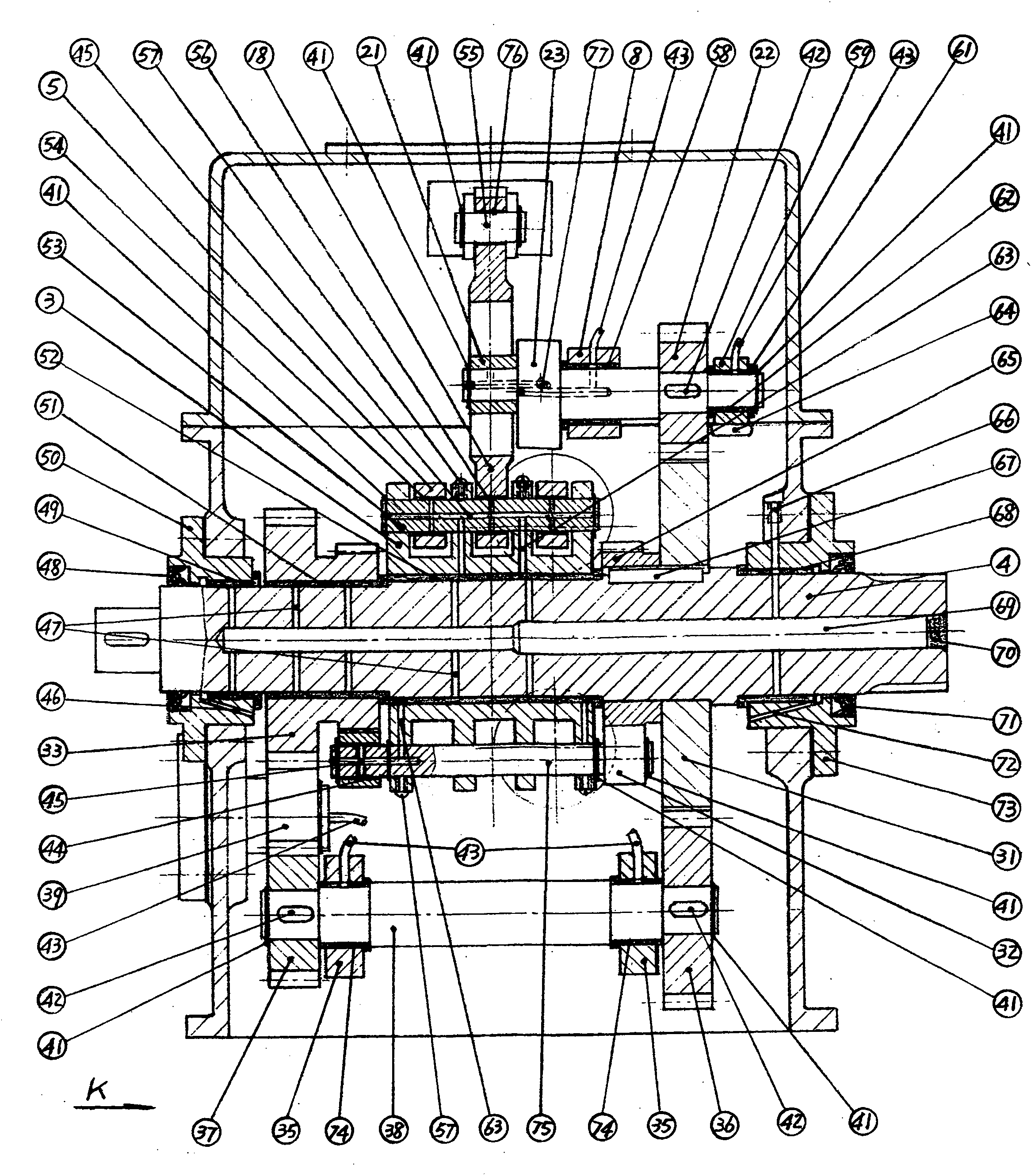

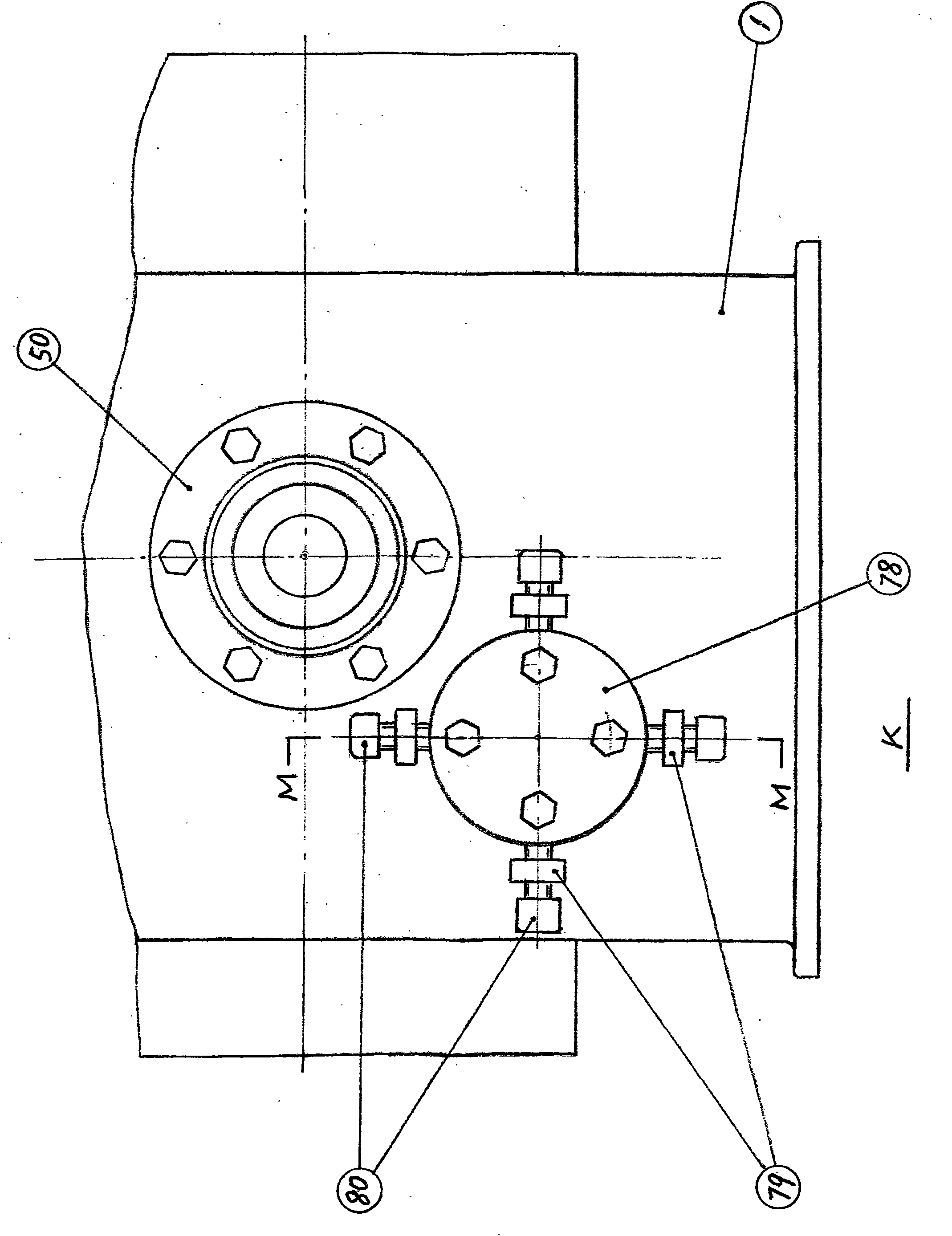

[0029] Combine below Figure 1 to Figure 5 The detailed description of the specific structure, installation and working conditions of the specific structure proposed by the present invention is not intended to limit the present invention.

[0030] The improvements of the present invention to the aforementioned two invention patents mainly include the following:

[0031] The first item is the addition of a toggle lever drive mechanism consisting of a swing arm 18, a swing rod 17, a hinge seat 16, an eccentric shaft 23, a slider 21, an eccentric shaft gear 22, and an eccentric shaft bearing seat 8, 59. The swing arm 18 is made of nodular cast iron. Its shape is similar to a rhombus, with rounded ends of the long axis, and processed with pin holes. The middle section of the swing arm is slightly thicker, and a long through hole is machined along the long axis. The side walls of the long through hole are polished. The pin hole at one end of the swing arm is equipped with a bronze b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com