Method for preparing hydrated manganese sulfate

A technology of monohydrate sulfuric acid and solution, applied in the directions of manganese sulfate, separation methods, chemical instruments and methods, etc., can solve the problem of MnO not using methods, etc., and achieve the effect of solving production capacity constraints and improving production capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

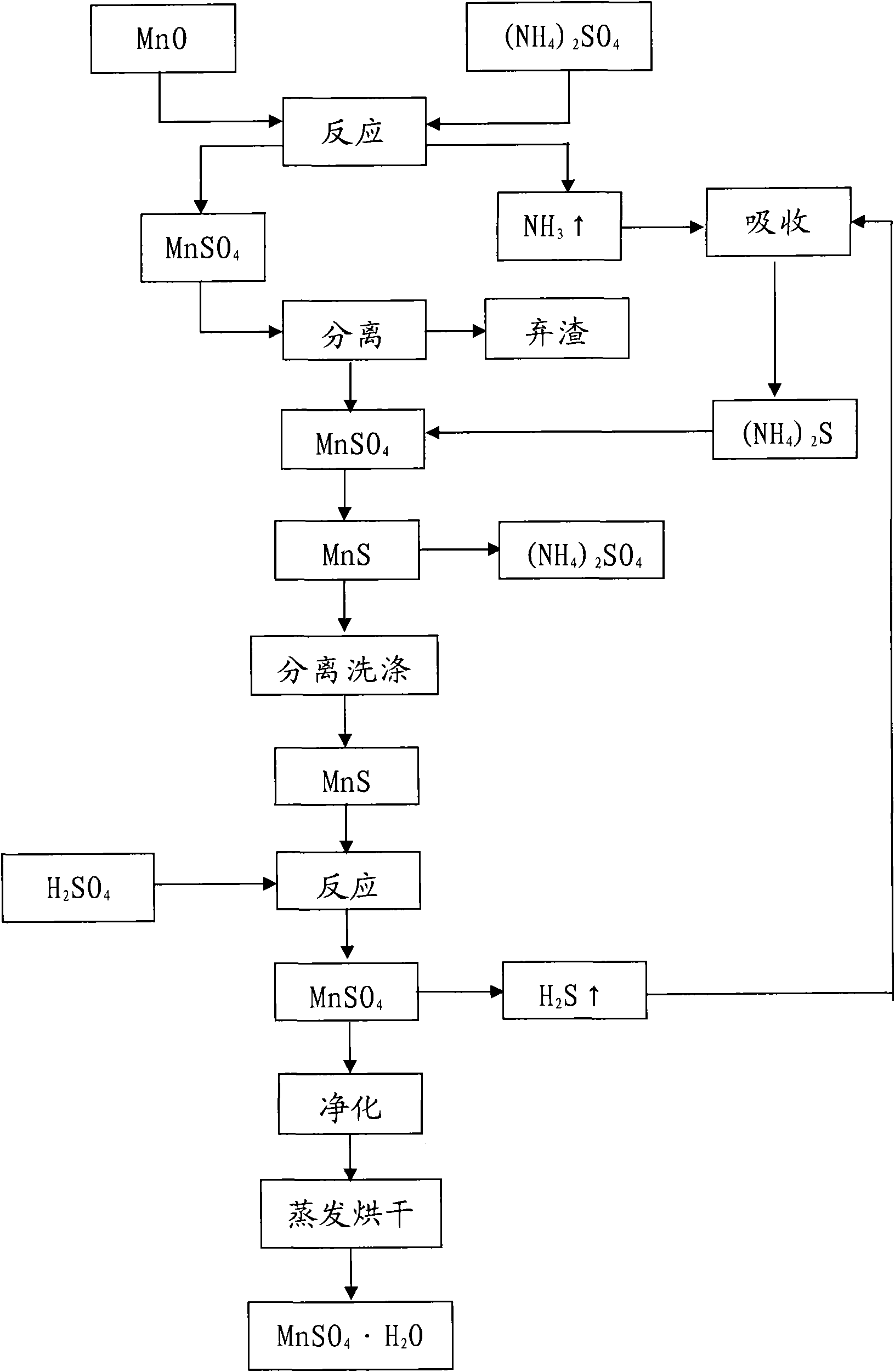

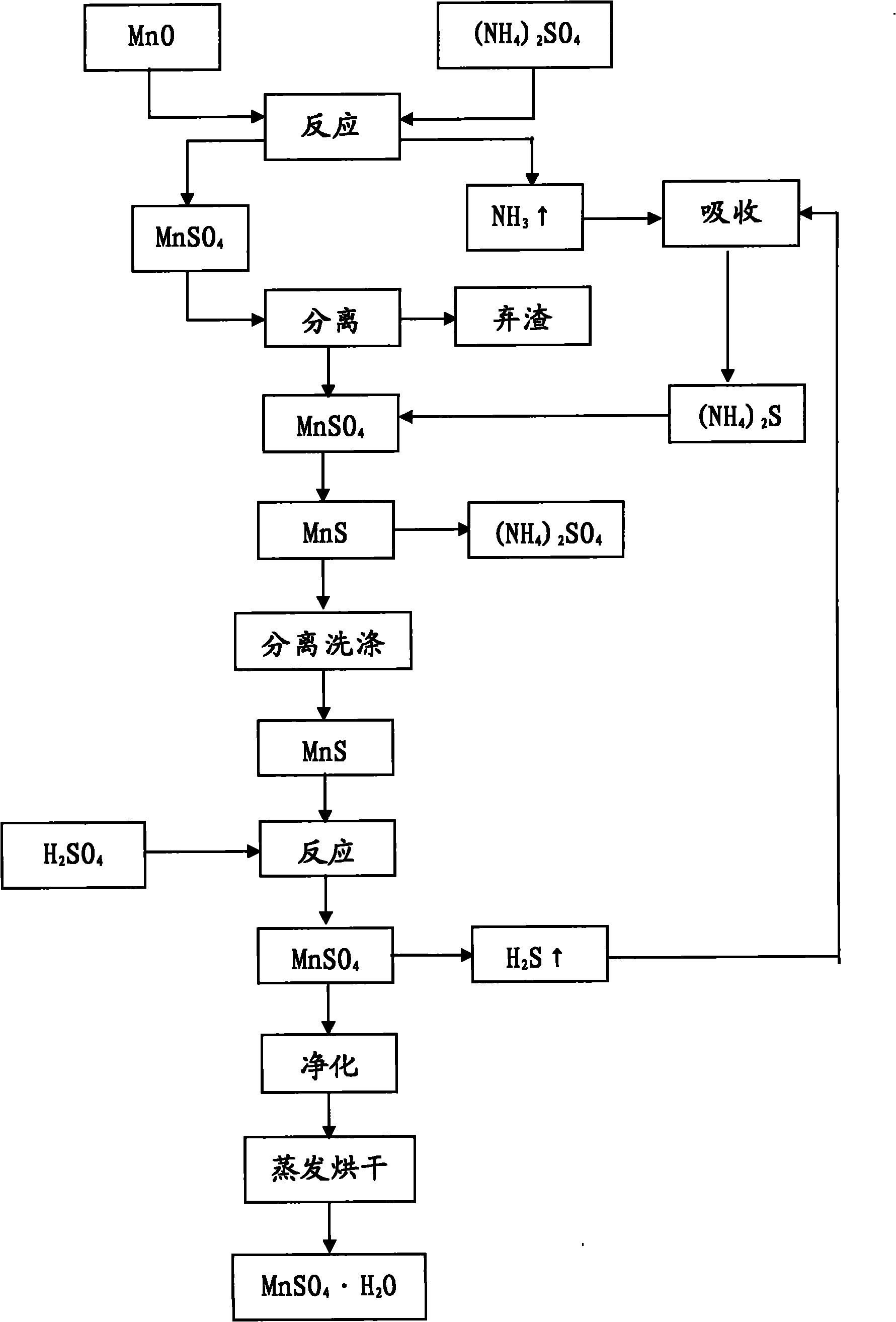

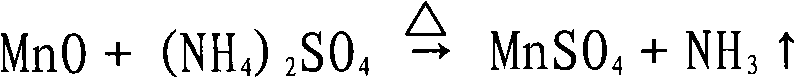

Method used

Image

Examples

Embodiment 1

[0029] Get the MnO (weight content 17.51%) that 1500gBa-Mn is combined (namely manganese dioxide ore powder and BaS solution reaction) to obtain and place in 5000mL beaker, add concentration and be 147g / L (NH 4 ) 2 SO 4 The solution was 3490mL, heated and reacted under stirring, the gas produced was recovered by a secondary bubbling absorption device, the device was heated to 100°C for 60 minutes, and the heating was stopped;

[0030] Separate the above solution by suction filtration, rinse the funnel with a small amount of deionized water, combine the filtrates, and measure MnSO 4 The concentration of the solution is 221.8g / L and the volume is 2443mL. Adding concentration under stirring is 1.47mol / L (NH 4 ) 2 S solution 2441ml equimolar reaction, keep stirring for 30 minutes, then separate by suction filtration, discard the filtrate, wash the filter cake with 60°C hot water, 1:5 ratio of material to water, wash for 2 hours, separate by suction filtration, discard the filtr...

Embodiment 2

[0033] The MnO (9.71% by weight) obtained by 1500g Ba-Sr combination (that is, the reaction of manganese dioxide ore powder and SrS solution) is placed in a 5000mL beaker, and the concentration of 130g / L (NH 4 ) 2 SO 4 The solution was 2084mL, heated and reacted under stirring, the gas generated was recovered by a secondary bubbling absorption device, the temperature of the device was raised to 100°C and maintained for 30 minutes, and the heating was stopped.

[0034] Separate the above solution by suction filtration, rinse the funnel with a small amount of deionized water, combine the filtrates, and measure MnSO 4 The concentration of the solution is 206.1mol / L, the volume is 1458mL, and the (NH4) concentration of 1.52mol / L is added under stirring 2 S solution 1309ml equimolar reaction, keep stirring for 30 minutes, then separate by suction filtration, discard the filtrate, wash the filter cake with 80°C hot water, 1:4 ratio of material to water for 2 hours, separate by suc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com